You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SingleSeat's Rangefinder (Scratch-built) *pics*

- Thread starter SingleSeat

- Start date

SingleSeat

Active Hunter

DL44 Blaster said:OK now that you have the "easy" stuff out of the way,....go paint the helmet

Steve

Maybe I'll just wait and get to work on the Blaster

Last edited by a moderator:

SingleSeat

Active Hunter

Nutcore said:wow, that if freakin awesome! are you gonna post blueprints?

I'm drawin' the last of the prints up for you guys now.

SingleSeat

Active Hunter

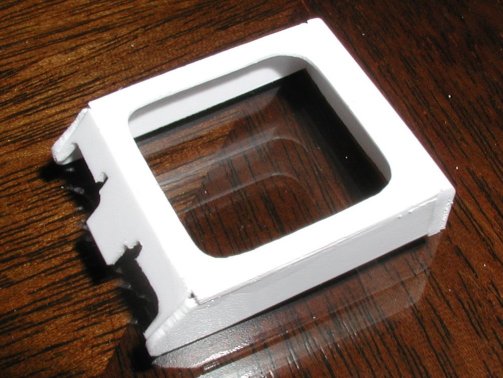

Hold on DL44, there’s still a bit more action left in these 2 ½ inches of black plastic  . Up next is what I call the window frame. It looks like a flip-up button protector since it has hinge holes on either side of a 45deg angled side (that allows the cover to flip all the way back in order to push the button) – it would be to a button that you wouldn’t want to push by accident.

. Up next is what I call the window frame. It looks like a flip-up button protector since it has hinge holes on either side of a 45deg angled side (that allows the cover to flip all the way back in order to push the button) – it would be to a button that you wouldn’t want to push by accident.

In this case, it’s just another assembly of .030” sheet styrene with one end made from .080” sheet. I cut the sides out, cemented them together, reinforced the interior with a super-small amount of 2-part epoxy (the clear locktite stuff is what I’ve been using). The centerpiece of the window required rounded corners and the dremel stepped up to the plate. With that piece, the window gets cut first, then the outside of the shape comes second. Once I could get all the parts together, I could putty the seems and sand the tips off the 45deg ends to blend with the slanted end. After everything was cut, blended, and sanded, I drilled the little “hinge” holes with dremel’s smallest drill bits and finished them with dremel’s smallest little ball-type engravers. They are about 0.8 - 0.9 mm in diameter.

In this case, it’s just another assembly of .030” sheet styrene with one end made from .080” sheet. I cut the sides out, cemented them together, reinforced the interior with a super-small amount of 2-part epoxy (the clear locktite stuff is what I’ve been using). The centerpiece of the window required rounded corners and the dremel stepped up to the plate. With that piece, the window gets cut first, then the outside of the shape comes second. Once I could get all the parts together, I could putty the seems and sand the tips off the 45deg ends to blend with the slanted end. After everything was cut, blended, and sanded, I drilled the little “hinge” holes with dremel’s smallest drill bits and finished them with dremel’s smallest little ball-type engravers. They are about 0.8 - 0.9 mm in diameter.

SingleSeat

Active Hunter

webchief said:You have GOT to be kidding me! This amount of detail in a two inch piece?

Dude... what do you do for a living? Incredible work!

<------ I stay busy

SingleSeat

Active Hunter

Flat black covered the piece and Testors Flat Tan weathered it, again with a tiny brush. Flicking a toothbrush would have been too random for me to duplicate the original. Finally some brown pastels, flaked onto the surface with a pin, and rubbed around with a small dry brush blended the weathering on the window frame.

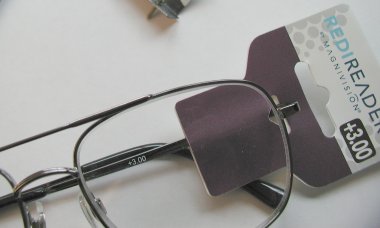

Since I’m a guy who doesn’t exactly need glasses, I had to go buy some and take the lenses out of a set of reading glasses ($8 at W/M) with a thick +3.00 correction factor. I cut out a square 23mm by 23mm of Duct tape and placed it in the middle of the lens on the [concave] inside. Then I covered the other side with another slab of Duct tape (to protect from minor scratches). I took two pieces of VERY dense black foam (from who knows where) and wrapped those in a scrap piece of Velcro (soft side). I placed this mess into a vice and used a coping saw to cut the 23mm square around the tape. The whole window frame is about 23mm, but I needed some extra room in the clear window to sand it down to perfection with the dremel.

**dremel cutting wheels and plastic reading glasses don’t get along…forget about it!...saw the piece by hand, it only takes a few seconds**

I rounded the corners of the clear piece also for a better fit. Now the piece wedges into the window frame nicely – no glue. I elected to have the concave side facing out since the ref. pics show a little upward bulge between the window frame and the clear RF part if you look through the side view (but I guess that doesn’t matter since I can switch it around if I want). I applied RTV silicone to adhere the window frame assembly to the RF clear part. If you use a healthy quantity, yet enough to not be oozing out the sides, it holds steady under jarring testing (I’m still curious about a replacement glue…maybe E6000…that doesn’t mar the RF clear part). The key is to set it, and let it dry for a day or two. Heck, I’ve got silicone holding the master link clip on my motorcycle chain too -- It'll hold. Also, the silicone cleans up easy wet or dry.

One point of note that I found was that in the ESB scenes where Fett is loading Solo into Slave I, his window frame is gone…I guess the real one just kept falling off, hah!

Since I’m a guy who doesn’t exactly need glasses, I had to go buy some and take the lenses out of a set of reading glasses ($8 at W/M) with a thick +3.00 correction factor. I cut out a square 23mm by 23mm of Duct tape and placed it in the middle of the lens on the [concave] inside. Then I covered the other side with another slab of Duct tape (to protect from minor scratches). I took two pieces of VERY dense black foam (from who knows where) and wrapped those in a scrap piece of Velcro (soft side). I placed this mess into a vice and used a coping saw to cut the 23mm square around the tape. The whole window frame is about 23mm, but I needed some extra room in the clear window to sand it down to perfection with the dremel.

**dremel cutting wheels and plastic reading glasses don’t get along…forget about it!...saw the piece by hand, it only takes a few seconds**

I rounded the corners of the clear piece also for a better fit. Now the piece wedges into the window frame nicely – no glue. I elected to have the concave side facing out since the ref. pics show a little upward bulge between the window frame and the clear RF part if you look through the side view (but I guess that doesn’t matter since I can switch it around if I want). I applied RTV silicone to adhere the window frame assembly to the RF clear part. If you use a healthy quantity, yet enough to not be oozing out the sides, it holds steady under jarring testing (I’m still curious about a replacement glue…maybe E6000…that doesn’t mar the RF clear part). The key is to set it, and let it dry for a day or two. Heck, I’ve got silicone holding the master link clip on my motorcycle chain too -- It'll hold. Also, the silicone cleans up easy wet or dry.

One point of note that I found was that in the ESB scenes where Fett is loading Solo into Slave I, his window frame is gone…I guess the real one just kept falling off, hah!

Last edited by a moderator:

Spideyfett

Well-Known Hunter

You've GOT to be kiddin ME!!!!!

Brilliant bro!!

Brilliant bro!!

Last edited by a moderator:

Jango Fett Jr

Well-Known Hunter

Holy freakin gosh.

The original part hasn't been found yet, but you've created the best imaginiable alternative. Amazing creativity and eye for detail.

The original part hasn't been found yet, but you've created the best imaginiable alternative. Amazing creativity and eye for detail.

Spideyfett

Well-Known Hunter

I didn't read this part till now...SingleSeatForever said:This simple little thread is dedicated to Spideyfett's My MS2 tutorial where you can learn about more than just painting a great Fett helmet!

WOW...thanks SSF....

hear that? That's my EGO BLOWING UP..

Again GREAT tutorial so far...

Last edited by a moderator:

Gonzo Fett

Active Hunter

wow this is really cool..I wonder if my briot lens cutter could cut out a lens that small....either way you did a great job cutting it by hand! Wow...most impressive. Talk about raising the bar!

good job! :cheers

good job! :cheers

SingleSeat

Active Hunter

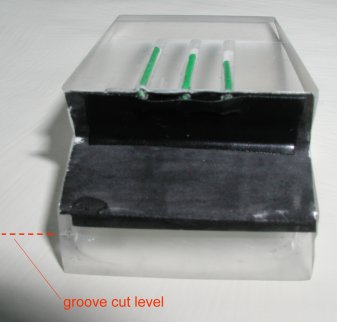

Almost wrapping up here  ! The clear part has a tiny groove cut into one end of it’s inside wall that serves to “click” into part of the steel bracket that is just barely too big – it wants to bite into the clear part. But with the groove, it just pops into place! I used the smallest Exacto saw blade for this cut (see hobby store – it’s a blade about 4.5” long). It’s not so easy to get this groove in the pictures so I showed where it is with dotted lines. It’s not very deep, maybe enough to catch your fingernail to know that it’s there, but not much more. No glue is required since the clear part is under too much pressure to go anywhere, and the welded and expoxied RF isn’t going anywhere either. To assemble the whole thing (such as after changing the batteries),

! The clear part has a tiny groove cut into one end of it’s inside wall that serves to “click” into part of the steel bracket that is just barely too big – it wants to bite into the clear part. But with the groove, it just pops into place! I used the smallest Exacto saw blade for this cut (see hobby store – it’s a blade about 4.5” long). It’s not so easy to get this groove in the pictures so I showed where it is with dotted lines. It’s not very deep, maybe enough to catch your fingernail to know that it’s there, but not much more. No glue is required since the clear part is under too much pressure to go anywhere, and the welded and expoxied RF isn’t going anywhere either. To assemble the whole thing (such as after changing the batteries),

1) Insert the Hyperdyne kit.

2) Slide the RF body onto the steel bracket.

3) Insert the clear part, narrow end first into the RF. Set the larger end of the clear part into the RF until it clicks into the setting groove. Make any adjustment necessary to the narrow end of the clear part to make it level.

There you have it. Ready to get good ranging on any pesky YT-1300 that tries to run! Simple as that.

1) Insert the Hyperdyne kit.

2) Slide the RF body onto the steel bracket.

3) Insert the clear part, narrow end first into the RF. Set the larger end of the clear part into the RF until it clicks into the setting groove. Make any adjustment necessary to the narrow end of the clear part to make it level.

There you have it. Ready to get good ranging on any pesky YT-1300 that tries to run! Simple as that.

Last edited by a moderator:

SingleSeat

Active Hunter

Bleahhh said:nice...any jango RFs for sale?

Nothin's for sale just yet, but maybe later

Last edited by a moderator:

Pirate BobaFett

New Hunter

That is one impressive rangefinder  !!!

!!!

Last edited by a moderator:

darkjediknight

New Hunter

Great job!

Last edited by a moderator:

Similar threads

- Replies

- 4

- Views

- 439

- Replies

- 0

- Views

- 217

- Replies

- 4

- Views

- 2,264

- Replies

- 6

- Views

- 925