Hi TDH,

While collaborating with John Haigh from Elstree Precision Co Ltd on the upcoming Elstree Metal Ears run for the ESB Hero helmets, we both found ourselves in need of some additional metal components. John decided that he wanted to make his own bordens and has offered to do a run for us as well. We are on the tail end of the research and development end of the project and looking for your input and feedback before going live with a sale thread.

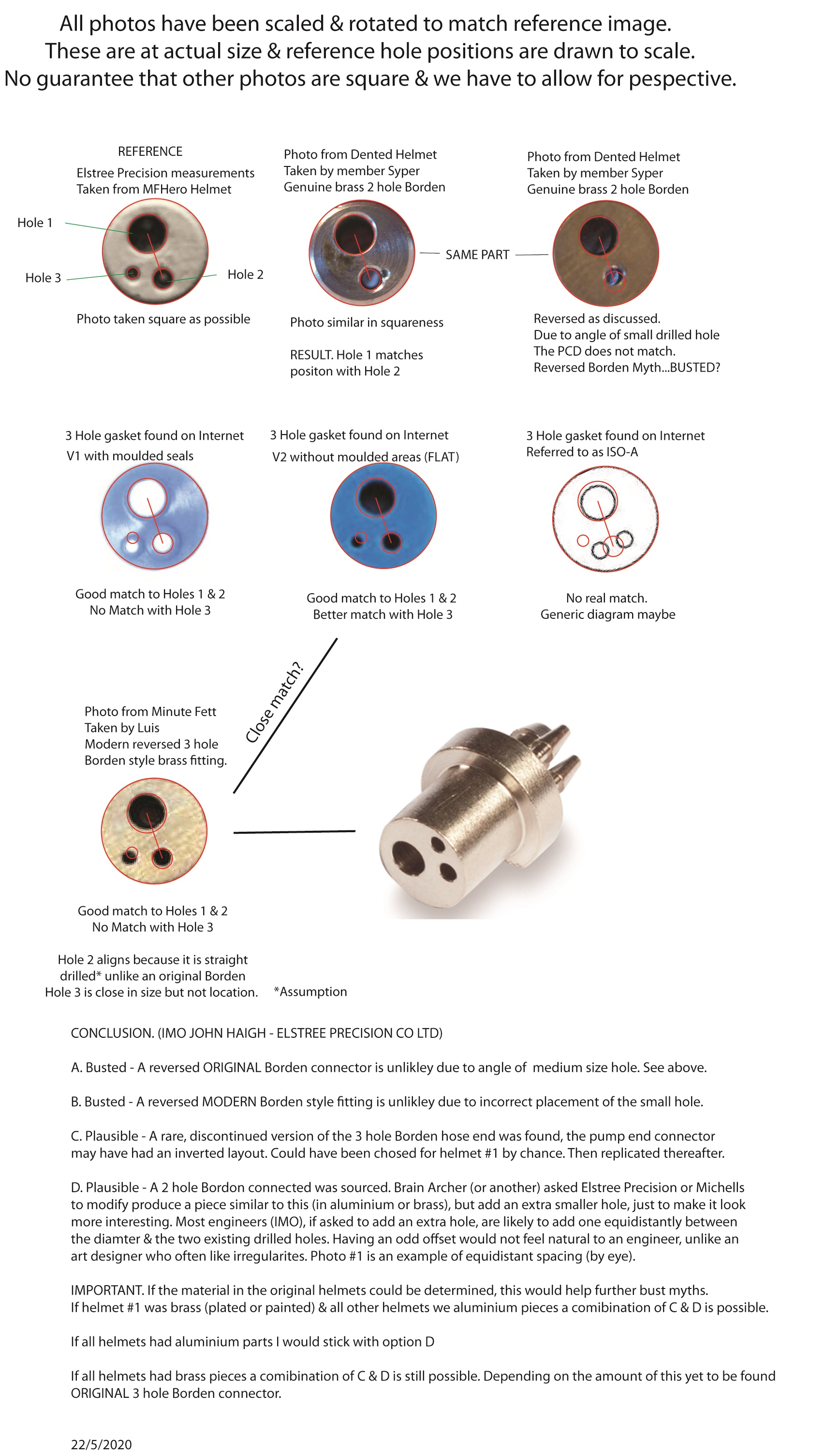

So, here is where we are at with a huge thanks to John for all of his hard work and devoted time to getting this right! He made the following reference to sum up of his research so far.

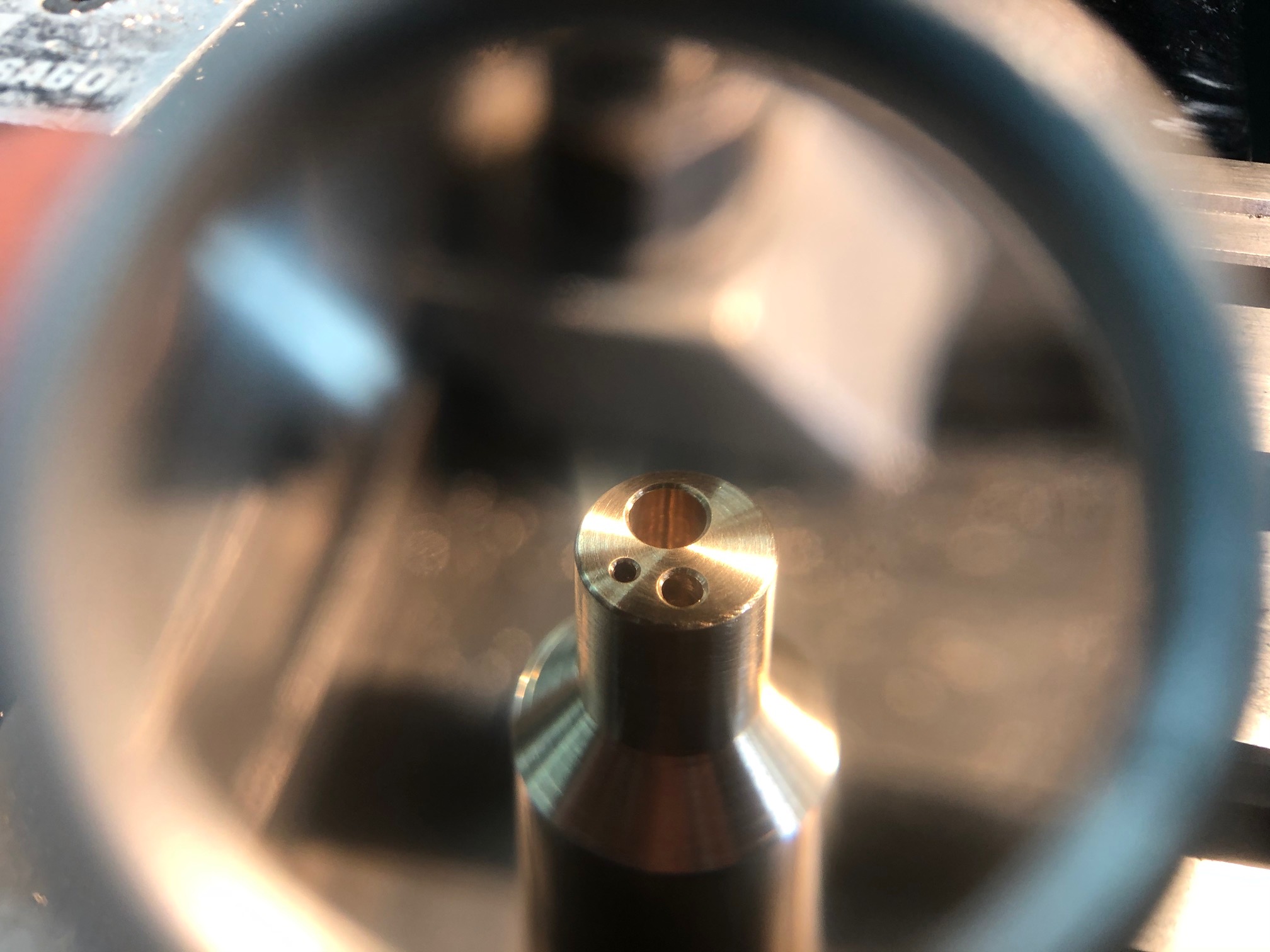

That being said, John decided to make this prototype borden from brass. He turned down a piece of stock to the diameter that he had measured from a raw casting of the ESB Hero helmet. He then added a chamfer by eye to suit the somewhat varied photos.

From the assessment data he had used on the computer, he was able to plot the exact co-ordinates he had achieved on the screen to Elstree's vintage milling machine. After drilling the 3 holes to the diameters that he had measured directly from the raw casting of the ESB Hero helmet, he added the chamfers.

Photographed here through a loupe:

Next, John trimmed to the borden to 9mm in length. (He suspects that they were 7-9mm looking at the inside helmet shots of various lineage helmets from the media section of TDH).

Then came the fun part. After an ultrasonic cleaning, John had the part electro plated in a vintage nickel plate inspired by a metal finishing expert.

We are quite happy with the results. What he was left with is a dull silver finish with a slight tarnished effect. Quite in keeping with a 40 year old component don’t you think?

Seen below though a jeweller's microscope:

John is totally happy with the orientation of the holes, but would appreciate some factual data on the hole sizes if anyone has it. So, if you have any info you would like to share, please free free to post it here or PM me if you would like to maintain discretion. We will make sure you get some bordens out of it if you can get us the info we are looking for!!

Even though John has treble checked the size of the larger hole, it does appear slightly larger than the one on the helmet. Maybe a bit of an optical illusion?? But John and I would really like to get it 100% right, so help us out

We would really like to know for sure if the ones in the helmet are indeed brass or aluminum (John finds it highly unlikely they would have been stainless steel).

Once we have the data mentioned above, John has said that he is happy to make a run of these for us and that he thinks he can produce them for (can't put the price here or it will be a sale thread, but less than most places serve dinner and an adult beverage plus shipping lol)

So, what do you think TDH? Help us get these right!

Thanks,

Steven and John

While collaborating with John Haigh from Elstree Precision Co Ltd on the upcoming Elstree Metal Ears run for the ESB Hero helmets, we both found ourselves in need of some additional metal components. John decided that he wanted to make his own bordens and has offered to do a run for us as well. We are on the tail end of the research and development end of the project and looking for your input and feedback before going live with a sale thread.

So, here is where we are at with a huge thanks to John for all of his hard work and devoted time to getting this right! He made the following reference to sum up of his research so far.

That being said, John decided to make this prototype borden from brass. He turned down a piece of stock to the diameter that he had measured from a raw casting of the ESB Hero helmet. He then added a chamfer by eye to suit the somewhat varied photos.

From the assessment data he had used on the computer, he was able to plot the exact co-ordinates he had achieved on the screen to Elstree's vintage milling machine. After drilling the 3 holes to the diameters that he had measured directly from the raw casting of the ESB Hero helmet, he added the chamfers.

Photographed here through a loupe:

Next, John trimmed to the borden to 9mm in length. (He suspects that they were 7-9mm looking at the inside helmet shots of various lineage helmets from the media section of TDH).

Then came the fun part. After an ultrasonic cleaning, John had the part electro plated in a vintage nickel plate inspired by a metal finishing expert.

We are quite happy with the results. What he was left with is a dull silver finish with a slight tarnished effect. Quite in keeping with a 40 year old component don’t you think?

Seen below though a jeweller's microscope:

John is totally happy with the orientation of the holes, but would appreciate some factual data on the hole sizes if anyone has it. So, if you have any info you would like to share, please free free to post it here or PM me if you would like to maintain discretion. We will make sure you get some bordens out of it if you can get us the info we are looking for!!

Even though John has treble checked the size of the larger hole, it does appear slightly larger than the one on the helmet. Maybe a bit of an optical illusion?? But John and I would really like to get it 100% right, so help us out

We would really like to know for sure if the ones in the helmet are indeed brass or aluminum (John finds it highly unlikely they would have been stainless steel).

Once we have the data mentioned above, John has said that he is happy to make a run of these for us and that he thinks he can produce them for (can't put the price here or it will be a sale thread, but less than most places serve dinner and an adult beverage plus shipping lol)

So, what do you think TDH? Help us get these right!

Thanks,

Steven and John

Last edited: