You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Visor installation?

- Thread starter SEEKER

- Start date

MilenkoFett

New Hunter

Alright. No need to ask, this thread has weighed all the pros and cons for mounting methods

. Thanks folks!

. Thanks folks!

mattman1138

Hunter

Alright. No need to ask, this thread has weighed all the pros and cons for mounting methods

. Thanks folks!

lol yea it's pretty thorough. I will say, for me, the chicago screw/binding post method was a the best way to go. I can replace the visor at any time I need. Takes more work than gluing but I think it was worth it.

MilenkoFett

New Hunter

Definitely Chicago screws. Seems most aesthetically pleasing, easier maintenance, and cleaner overall.

Radioman1017

New Hunter

Hello all,

I have a Don Post helmet from the mid-90's. (Yes, it's real because that's when I bought it.)

I need to install a visor and am confused on the "T" patterns. Which one do I need for this helmet?

Also, I saw someone mention a ring that could be constructed and placed inside to prevent warping. Can someone provide details?

Thanks much!

Mark

I have a Don Post helmet from the mid-90's. (Yes, it's real because that's when I bought it.)

I need to install a visor and am confused on the "T" patterns. Which one do I need for this helmet?

Also, I saw someone mention a ring that could be constructed and placed inside to prevent warping. Can someone provide details?

Thanks much!

Mark

mattman1138

Hunter

I didn't use a visor from t-visor, used a welding faceshield and cut it myself, much thicker. However, the chicago screws, I used either 3/16 in x 1/4 in. They work perfectly. If they seem to small go longer but I have small rubber o-rings between the screw and the inside of the visor (to protect the visor and make the contact tighter so it doesn't move around. Hope this helps.

Artakha

Active Hunter

Are T-Visors pre-curved? Also does anyone know the thickness of the material they use? I found some 1/8" Chicago screws but want to be sure that isn't too short if the visor material is thicker..

Yeah they're pre-curved, but you will still probably want to take a heat gun or similar and bend it to fit your helmet. The visor thickness is something like 2-3 millimeters.

Moonsault

New Hunter

Yeah they're pre-curved, but you will still probably want to take a heat gun or similar and bend it to fit your helmet. The visor thickness is something like 2-3 millimeters.

Thanks for the info! I went with a T-Visor and love it! Great quality and it looks fantastic! Highly recommended! Yes a little more than a welding mask I guess, but the extra thickness and sturdyness make it much better and far higher quality in my opinion.

Artakha

Active Hunter

Thanks for the info! I went with a T-Visor and love it! Great quality and it looks fantastic! Highly recommended! Yes a little more than a welding mask I guess, but the extra thickness and sturdyness make it much better and far higher quality in my opinion.

Nice little Fett corner you got there!

Last edited by a moderator:

Moonsault

New Hunter

Nice little Fett corner you got there!

lol thanks! Tip of the iceberg

Artakha

Active Hunter

lol thanks! Tip of the iceberg

lol...wow!

Last edited by a moderator:

Lynn TXP 0369

Well-Known Hunter

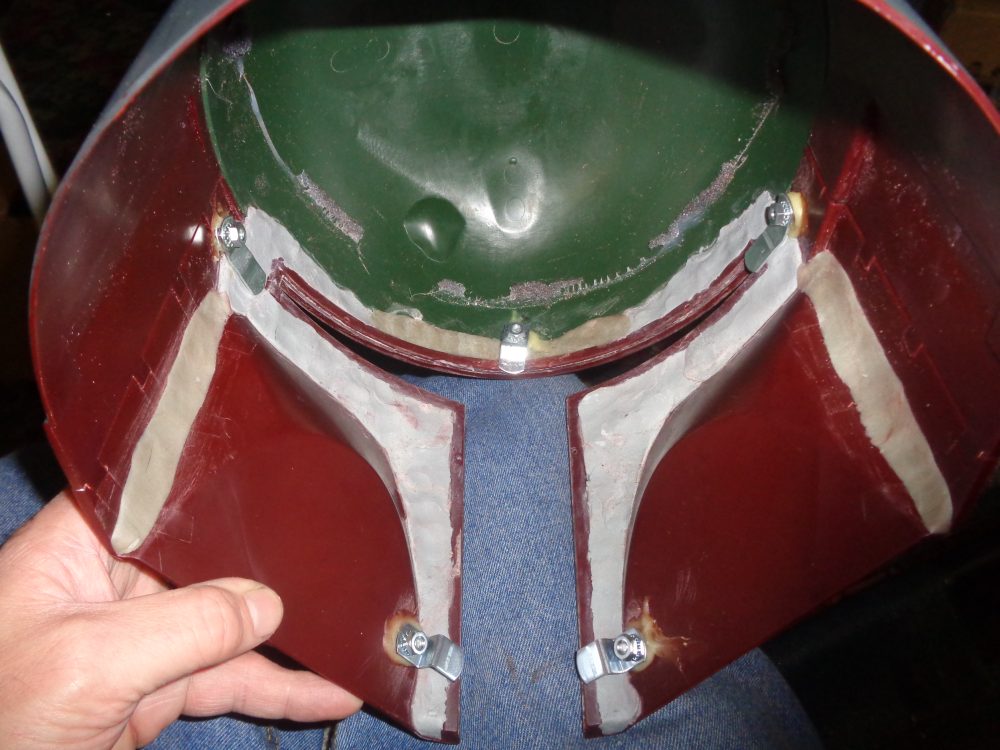

My install in my Target helmet.

I used pin post screws with the screw part epoxied to the helmet, modified picture hangers, and nuts to hold everything together. I got to find some 8/32 thumb nuts to fit the screws instead of the nuts as it will make visor removal much easier.

No glue, no fuss no muss easy visor removal.

My old MSH was similar.

Lynn

I used pin post screws with the screw part epoxied to the helmet, modified picture hangers, and nuts to hold everything together. I got to find some 8/32 thumb nuts to fit the screws instead of the nuts as it will make visor removal much easier.

No glue, no fuss no muss easy visor removal.

My old MSH was similar.

Lynn

intwenothor

Well-Known Hunter

This is effectively a bit of a double post but as this thread is a sticky and mine ain't it can stand to be reposted. Here was my attempt at accurate visor installation according to the best available images of the interior of screen helmets I had available at the time:

In my opinion it's best to have the visor area cut out and sanded properly before you start installation. You might try before that's done but then your visor won't fit as well. You can buy pre made visors from a number of vendors but there wasn't a boba fett visor shop in 1978 so I won't be using one. My way is more fun too. When I first started looking at this I was thinking that those guys in 1978 were crazy and that from a design point of view the chicago screw method was better. Actually I've changed my mind and think this is probably one of the better methods to attach a visor. One of the great advantages is that the visor is a proper rigid fit rather than constantly fighting the wish of flexible welding visors to return to flat.

The first thing you'll need to do is buy some A4 sheets of 3mm dark grey smoked perspex. It'll likely come in packs of 5 or 10 but don't worry about that as you may not get it right first time and perspex is brittle and prone to snapping so your spares will come in handy (I went through 7 sheets before I was happy).

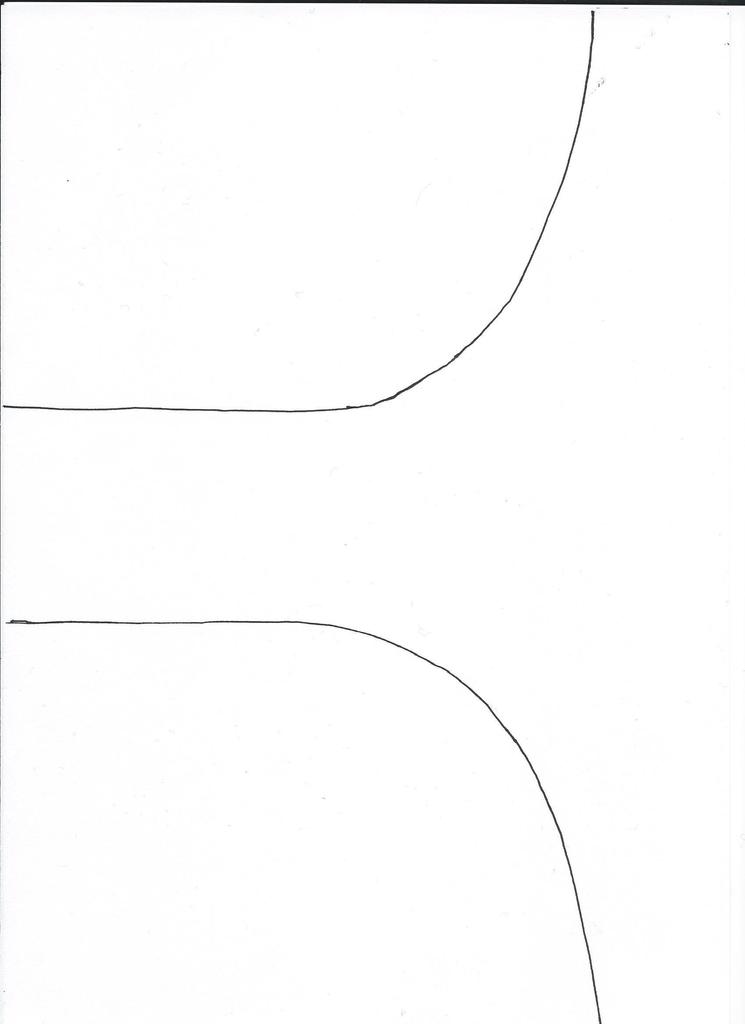

Then you'll need to take some measurements from your helmet to come up with a general visor shape and from that you'll make a template. Here's my template which should work for most helmets but will probably work best for those in the MR size and shape range.

This is an scan of a drawing of the outside of the template I cut out using my measurements. If you're thinking it looks a bit untidy and uneven then you're right but as the helmet is not symetrical and as you'll be trimming. sanding and tweaking after the initial cutting that really doesn't matter. The bottom section is deliberately left overlong and it shall remain so on the visor until the visor fitting is complete when it will then be trimmed to match the fit of the visor to the helmet.

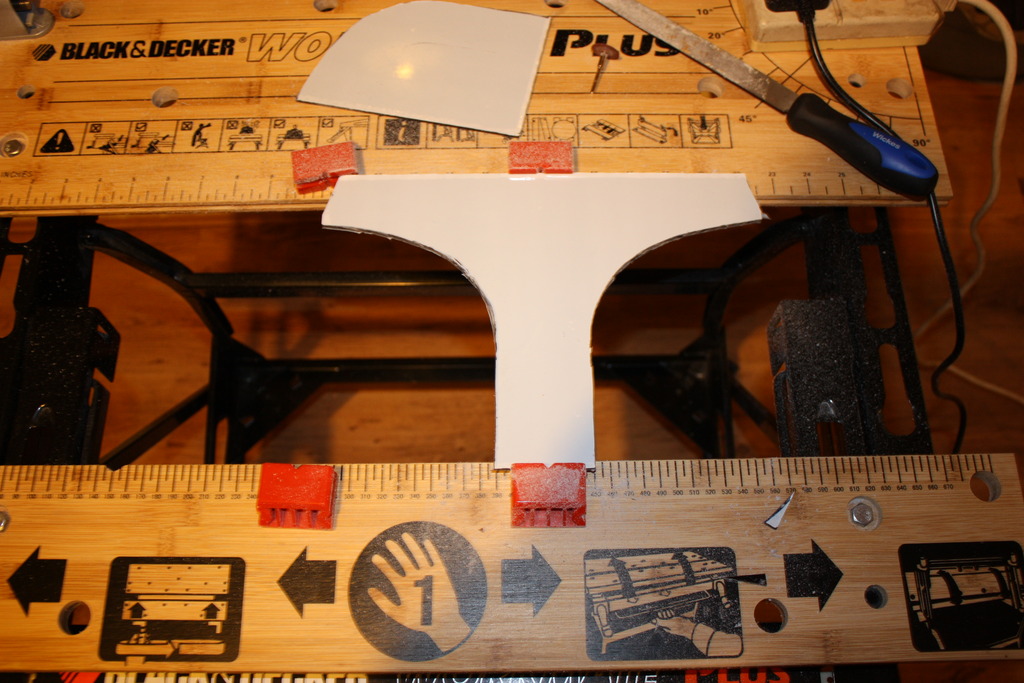

Once you've done the cutting you'll end up with something like this:

This was actually an early one I didn't end up using. I hand cut mine which was more difficult but I suspect it was how it was done back then. The visor that is taped inside the PP2 is pretty untidy in a handcut kind of way. I could be wrong of course.

Avoid the temptation to remove the protective film if you can because if you remove it you run the risk of marking it when fitting it.

Now, this next method is really only going to be available to those of you working with fibreglass helmets. Those with resin lids that warp under heat won't be able to do this.

Use a heat gun (mine's a black and decker) to warm your visor so it becomes mildly flexible and then lay it on the OUTSIDE of your helmet and then apply a bit more heat unitl it starts to match the shape of the curve of the outside of the helmet. Let it cool slowly for a bit until it becomes slightly less flexible and then place it INSIDE your helmet and heat some more to match the inside curve. Once it's more or less where it needs to be place it in cold water to cool it quickly and set to shape. The story won't end here and there'll be lots of trimming and minor reheats to get a better fit but that's the essence of it.

Once you've got that good fit the visor will actully sit in place with minimal pressure. Tape your visor into place using gaffer tape. For the next phase you'll need some visor clips. It will be easier to do the bottom set first so start there. I used milliput to fix mine into place (i'll paint it a better colour match later). Enusre the screws are in place in the tabs but after you've fitted the tabs make sure there is no pressure on the screws (because that will push the tabs out of place). Once you've got a decent placement you'll need to LEAVE IT ALONE FOR 24 HOURS so it can cure properly. This is roughly where you'll end up (you can't tell from this picture but the visor is long at the bottom because it hasn't yet been trimmed).

I'm no good with anything metal or technical so following some discussion with kurtyboy I turned to Sidewinder for these. There was an initial consultation in which I provided SAS with not very much material and he provided me a prototype set. Based on those I then sent SAS a drawing with some revisions and he made me a revised set. On arrival I could see they would be the ones. I made some minor tweaks to them before installation. If you want a set of clips sidewinder is your man.

After the lower set were cured I finished laying the upper clips. Sidewinder supplied me with two little aluminium squares with threaded holes. In order to afix one I rolled two little milliput sausages and squeezed them either side of the screw hole to give a platform to the square to sit on and allow a little room underneath for the screw to drop into. Then I built up around the square to lock it into place. Again 24 hours for curing is required. After that I trimmed all four screws to length and fitted the visor in.

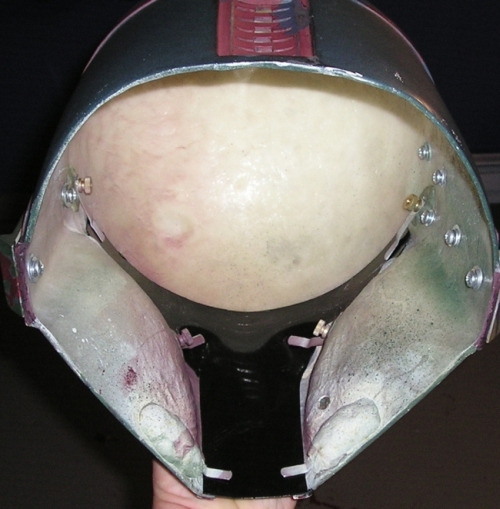

It's difficult to get inside the helmet in such a way as to show exactly what's going on but this should give the idea. Note these upper screws are steel domed like the ESB ones whereas the bottom are brass cheese heads.

Here's the interior as it stands. Cradle is just laid in. Mark off the bottom of the visor for trimming with some tape now that it is fitted and then cut, trim, and sand to for the final fit.

Live the dream

Andy

In my opinion it's best to have the visor area cut out and sanded properly before you start installation. You might try before that's done but then your visor won't fit as well. You can buy pre made visors from a number of vendors but there wasn't a boba fett visor shop in 1978 so I won't be using one. My way is more fun too. When I first started looking at this I was thinking that those guys in 1978 were crazy and that from a design point of view the chicago screw method was better. Actually I've changed my mind and think this is probably one of the better methods to attach a visor. One of the great advantages is that the visor is a proper rigid fit rather than constantly fighting the wish of flexible welding visors to return to flat.

The first thing you'll need to do is buy some A4 sheets of 3mm dark grey smoked perspex. It'll likely come in packs of 5 or 10 but don't worry about that as you may not get it right first time and perspex is brittle and prone to snapping so your spares will come in handy (I went through 7 sheets before I was happy).

Then you'll need to take some measurements from your helmet to come up with a general visor shape and from that you'll make a template. Here's my template which should work for most helmets but will probably work best for those in the MR size and shape range.

This is an scan of a drawing of the outside of the template I cut out using my measurements. If you're thinking it looks a bit untidy and uneven then you're right but as the helmet is not symetrical and as you'll be trimming. sanding and tweaking after the initial cutting that really doesn't matter. The bottom section is deliberately left overlong and it shall remain so on the visor until the visor fitting is complete when it will then be trimmed to match the fit of the visor to the helmet.

Once you've done the cutting you'll end up with something like this:

This was actually an early one I didn't end up using. I hand cut mine which was more difficult but I suspect it was how it was done back then. The visor that is taped inside the PP2 is pretty untidy in a handcut kind of way. I could be wrong of course.

Avoid the temptation to remove the protective film if you can because if you remove it you run the risk of marking it when fitting it.

Now, this next method is really only going to be available to those of you working with fibreglass helmets. Those with resin lids that warp under heat won't be able to do this.

Use a heat gun (mine's a black and decker) to warm your visor so it becomes mildly flexible and then lay it on the OUTSIDE of your helmet and then apply a bit more heat unitl it starts to match the shape of the curve of the outside of the helmet. Let it cool slowly for a bit until it becomes slightly less flexible and then place it INSIDE your helmet and heat some more to match the inside curve. Once it's more or less where it needs to be place it in cold water to cool it quickly and set to shape. The story won't end here and there'll be lots of trimming and minor reheats to get a better fit but that's the essence of it.

Once you've got that good fit the visor will actully sit in place with minimal pressure. Tape your visor into place using gaffer tape. For the next phase you'll need some visor clips. It will be easier to do the bottom set first so start there. I used milliput to fix mine into place (i'll paint it a better colour match later). Enusre the screws are in place in the tabs but after you've fitted the tabs make sure there is no pressure on the screws (because that will push the tabs out of place). Once you've got a decent placement you'll need to LEAVE IT ALONE FOR 24 HOURS so it can cure properly. This is roughly where you'll end up (you can't tell from this picture but the visor is long at the bottom because it hasn't yet been trimmed).

I'm no good with anything metal or technical so following some discussion with kurtyboy I turned to Sidewinder for these. There was an initial consultation in which I provided SAS with not very much material and he provided me a prototype set. Based on those I then sent SAS a drawing with some revisions and he made me a revised set. On arrival I could see they would be the ones. I made some minor tweaks to them before installation. If you want a set of clips sidewinder is your man.

After the lower set were cured I finished laying the upper clips. Sidewinder supplied me with two little aluminium squares with threaded holes. In order to afix one I rolled two little milliput sausages and squeezed them either side of the screw hole to give a platform to the square to sit on and allow a little room underneath for the screw to drop into. Then I built up around the square to lock it into place. Again 24 hours for curing is required. After that I trimmed all four screws to length and fitted the visor in.

It's difficult to get inside the helmet in such a way as to show exactly what's going on but this should give the idea. Note these upper screws are steel domed like the ESB ones whereas the bottom are brass cheese heads.

Here's the interior as it stands. Cradle is just laid in. Mark off the bottom of the visor for trimming with some tape now that it is fitted and then cut, trim, and sand to for the final fit.

Live the dream

Andy

KanoFett

New Hunter

Hey all... I'm brand new to the site, but I've been lurking forever. I started building my first Boba Fett costume in the late 90's and have used this site as a resource often.

When it was time to replace the old flimsy visor in my Don Post helmet, I read the install options and went with the Chicago screw method. It worked, but I wasn't very happy with the overall appearance of what was available from the hardware stores. Thanks to my PRIMARY hobby (firearms) I was able to find some specific hardware that was more suitable for my Visor install using the Chicago Screw methods.

I hope I'm not breaking any rules by providing brand names. I am not affiliated with any of these companies and I will not include links to specific sites.

First thing I noticed was how long the Chicago screws were. They stick out way past the visor, uncomfortably close to my face, and they just looked sloppy. The BlackHawk "Serpa" holsters use extremely short chicago screws that leave no overhang and are already black so they hide very well. I won't post any links, but if you just google "Blackhawk Serpa screws" you'll find an assorted pack of replacement hardware for less than $6.

The second issue I wanted to deal with was the washers I tried were a little too soft and flimsy. I was looking for something less "rubbery". There's a holster company, appropriately named "Alien Gear" that sells a "Mod Pack Plus" that runs about $7. It is available with either black or green hard rubber washers of various thicknesses as well as screws of various lengths. There is also a type of T-nut in the Mod Plus pack, but it's got "teeth" to bite into leather and prevent turning, so I didn't want to use that since the teeth would be facing the visor.

I don't have any pics here, but by using those 2 sets of hardware, I was able to install my visor in a way that I thought was much cleaner, less obvious, and didn't protrude as far into the helmet space that's already taken up by my huge cranium.

When it was time to replace the old flimsy visor in my Don Post helmet, I read the install options and went with the Chicago screw method. It worked, but I wasn't very happy with the overall appearance of what was available from the hardware stores. Thanks to my PRIMARY hobby (firearms) I was able to find some specific hardware that was more suitable for my Visor install using the Chicago Screw methods.

I hope I'm not breaking any rules by providing brand names. I am not affiliated with any of these companies and I will not include links to specific sites.

First thing I noticed was how long the Chicago screws were. They stick out way past the visor, uncomfortably close to my face, and they just looked sloppy. The BlackHawk "Serpa" holsters use extremely short chicago screws that leave no overhang and are already black so they hide very well. I won't post any links, but if you just google "Blackhawk Serpa screws" you'll find an assorted pack of replacement hardware for less than $6.

The second issue I wanted to deal with was the washers I tried were a little too soft and flimsy. I was looking for something less "rubbery". There's a holster company, appropriately named "Alien Gear" that sells a "Mod Pack Plus" that runs about $7. It is available with either black or green hard rubber washers of various thicknesses as well as screws of various lengths. There is also a type of T-nut in the Mod Plus pack, but it's got "teeth" to bite into leather and prevent turning, so I didn't want to use that since the teeth would be facing the visor.

I don't have any pics here, but by using those 2 sets of hardware, I was able to install my visor in a way that I thought was much cleaner, less obvious, and didn't protrude as far into the helmet space that's already taken up by my huge cranium.

Last edited by a moderator:

Similar threads

- Replies

- 2

- Views

- 1,580

- Replies

- 0

- Views

- 303

- Replies

- 2

- Views

- 2,832