RF Servo Tutorial

Here is the tutorial for the Radio Shack Zip Zap mini RC.

Here are the materials you will need to complete this project:

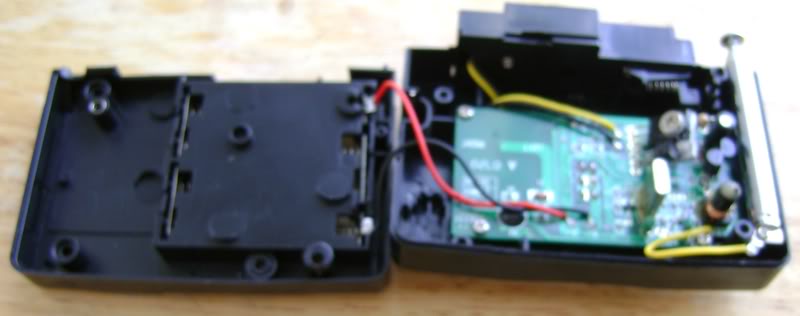

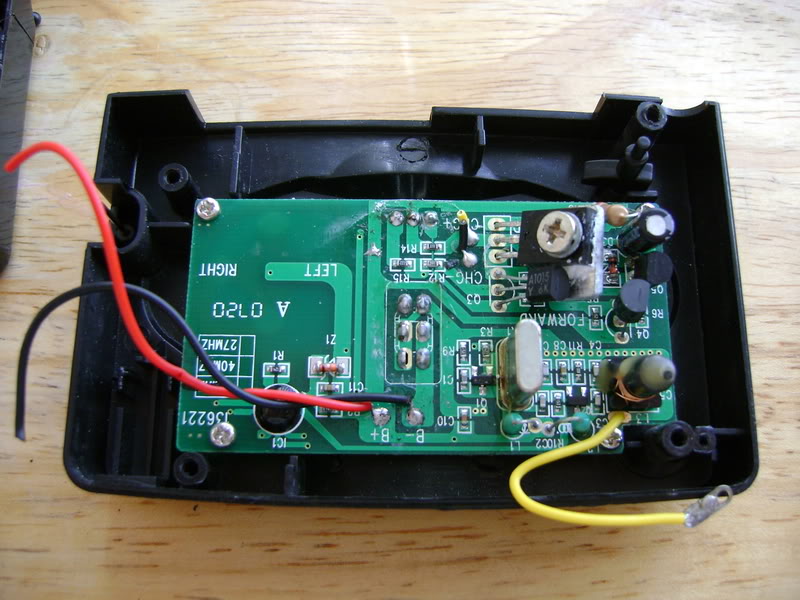

Flip the RC unit over and remove the screws from the back panel.

Pull the panel off carefully as not to pull the leads off the board.

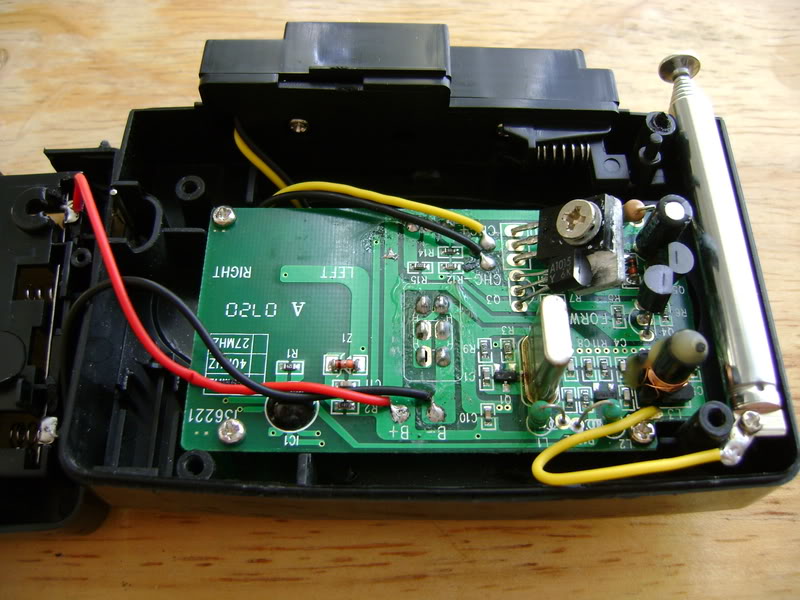

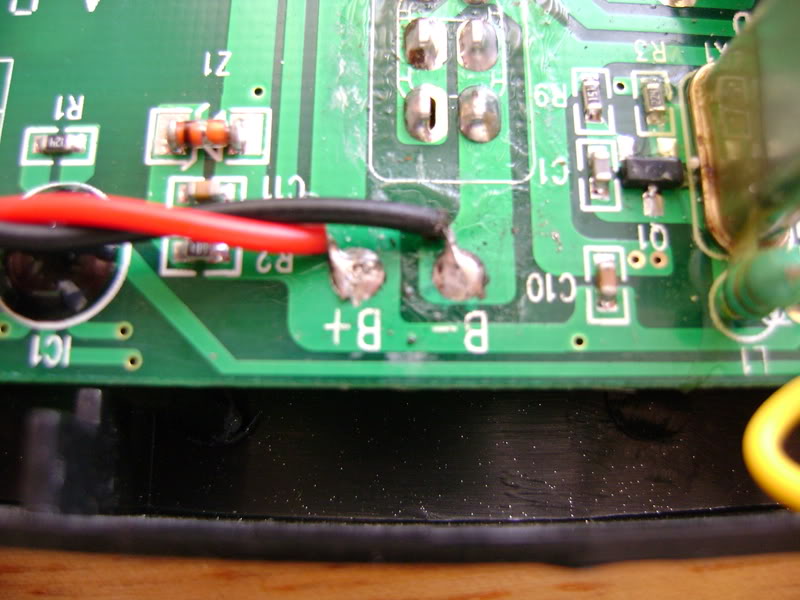

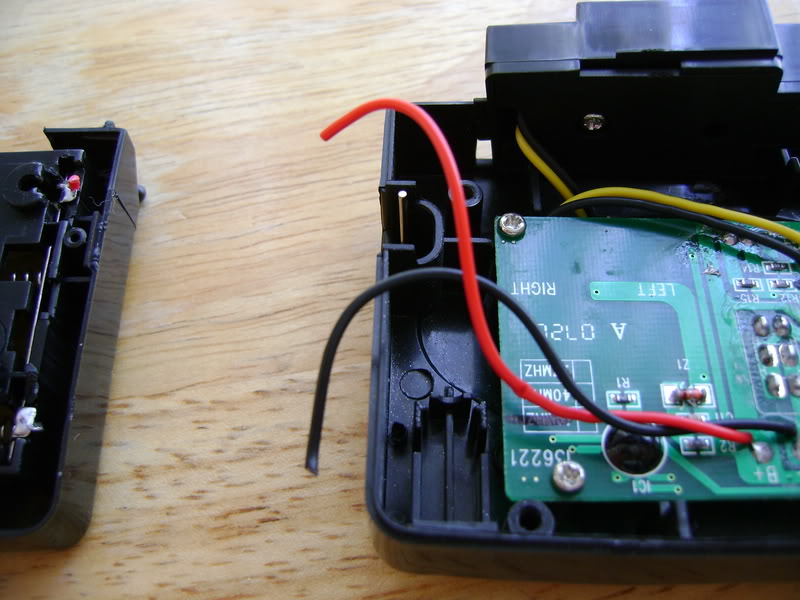

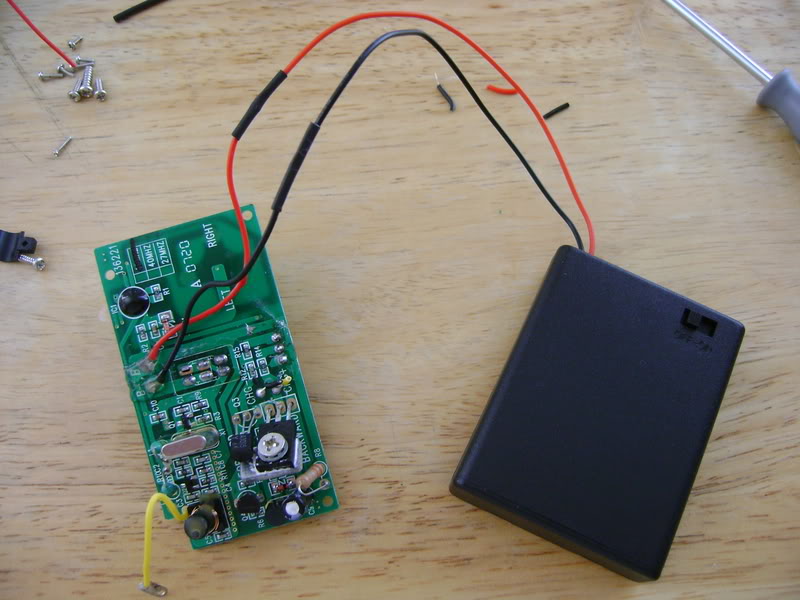

Here you can see the red and black power supply wires going to the board

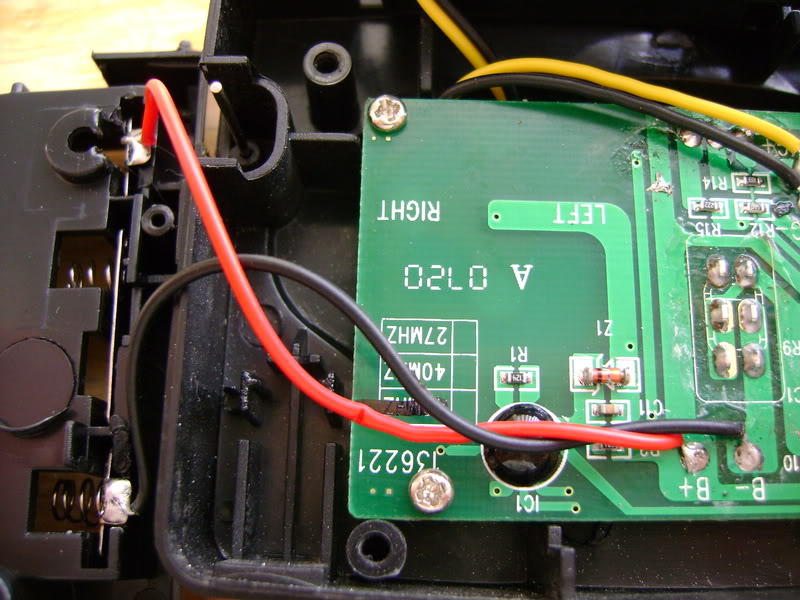

Follow the power supply wires to the battery compartment in the back panel

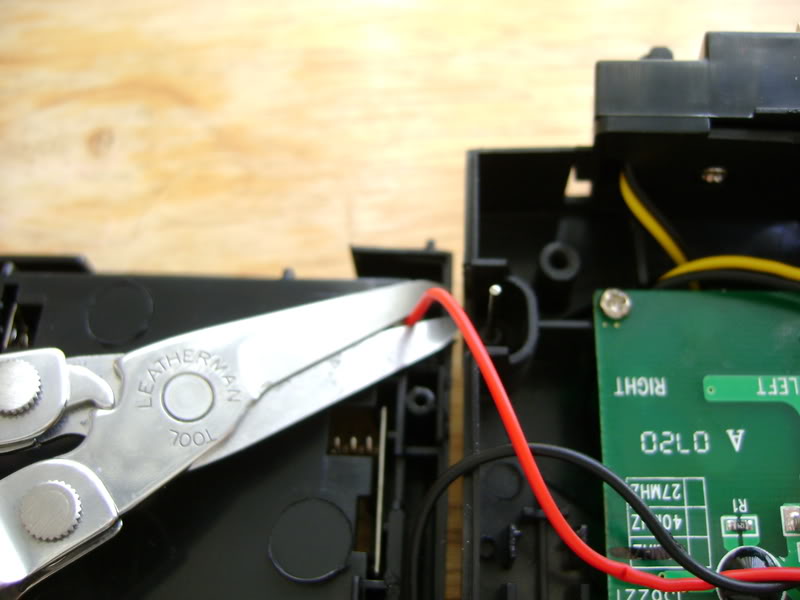

Cut the red and black wires on the battery compartment in the back panel

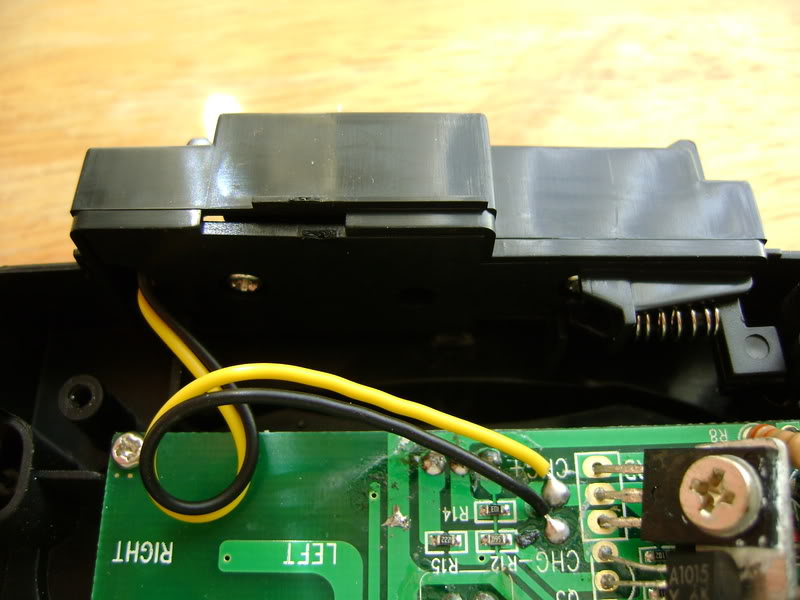

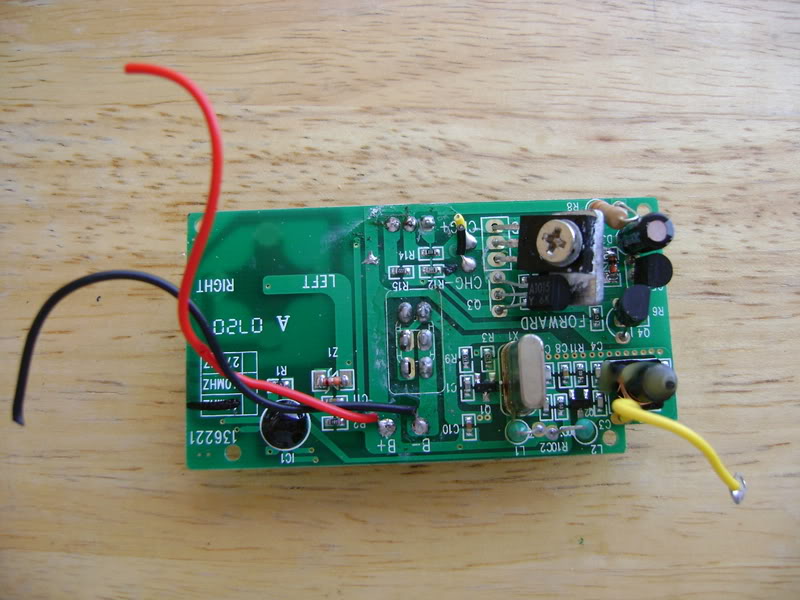

Here you can see the yellow and black wires for the charger unit. Cut them down to the board as it will not be needed for this project. The charger unit pops right off the top then put it aside.

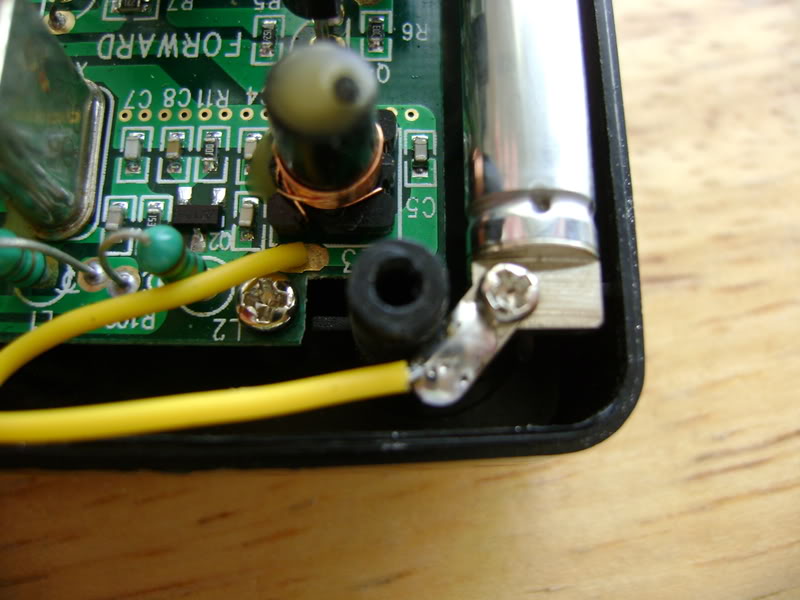

Here you can see the transmitter antenna and wire. Remove the screw that attaches the yellow wire to the base of the antenna post.

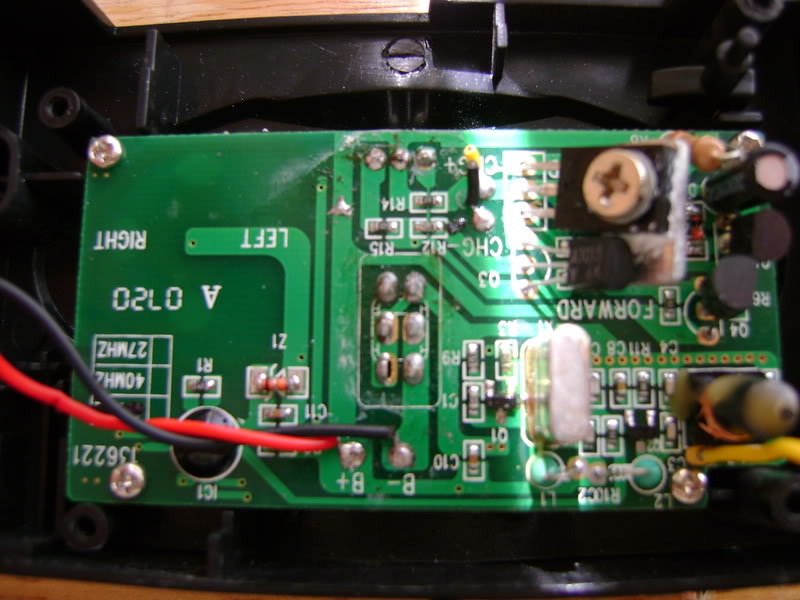

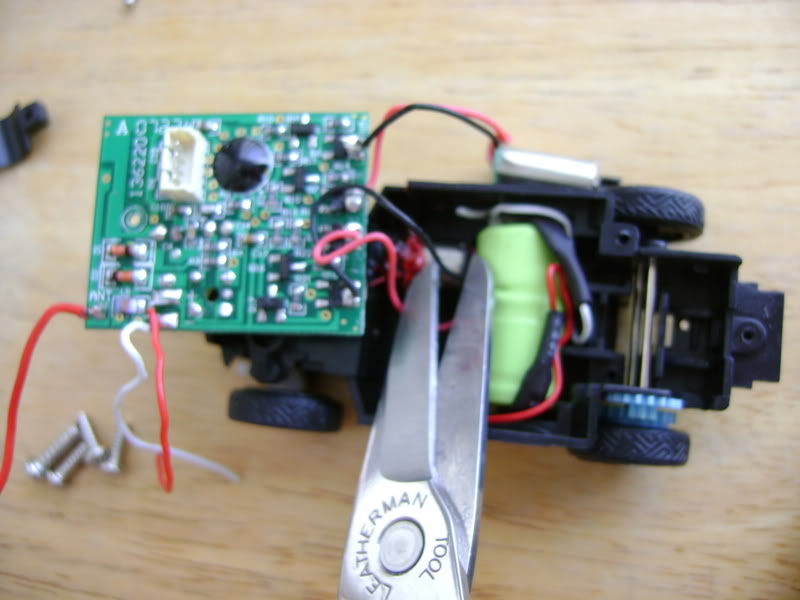

Here you can see 4 board screws, remove them and pull the board off the front panel

Hot glue the power supply black and red wire leads to the board to prevent them from breaking off.

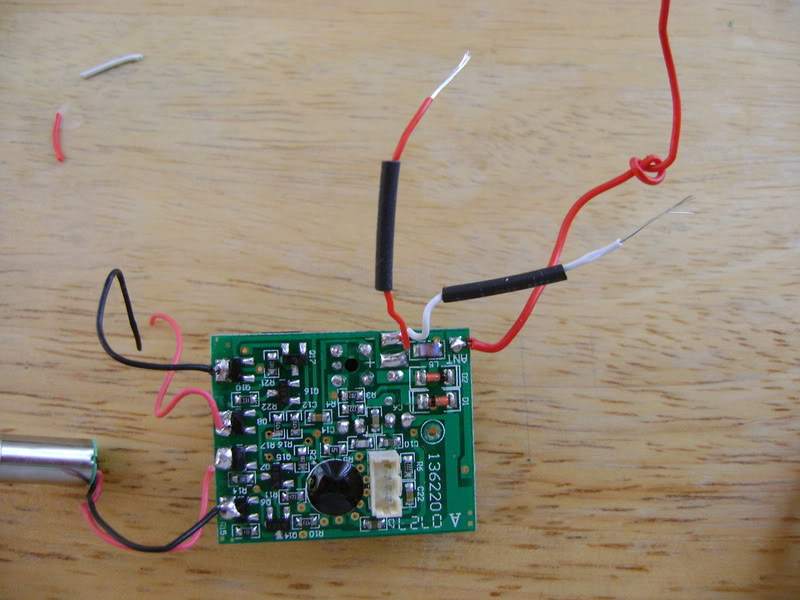

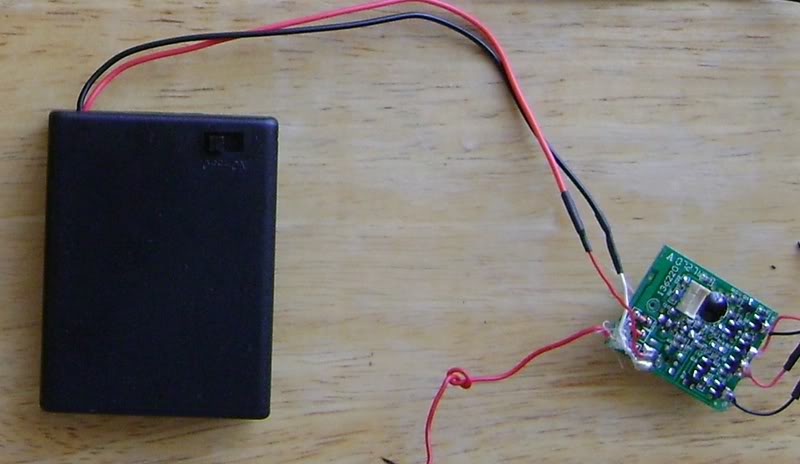

Slip on two short strips of heatshrink tubing on the power supply black and red wires then twist the exposed ends with wires from the AAA battery box with a switch. Solder the twisted wire ends then slip the heatshrink tubing over the soldered ends and heat with heat gun.

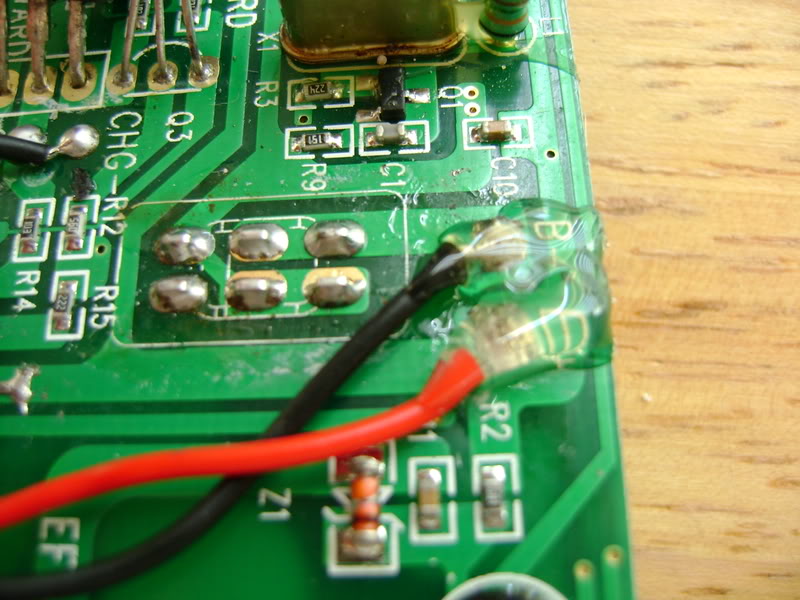

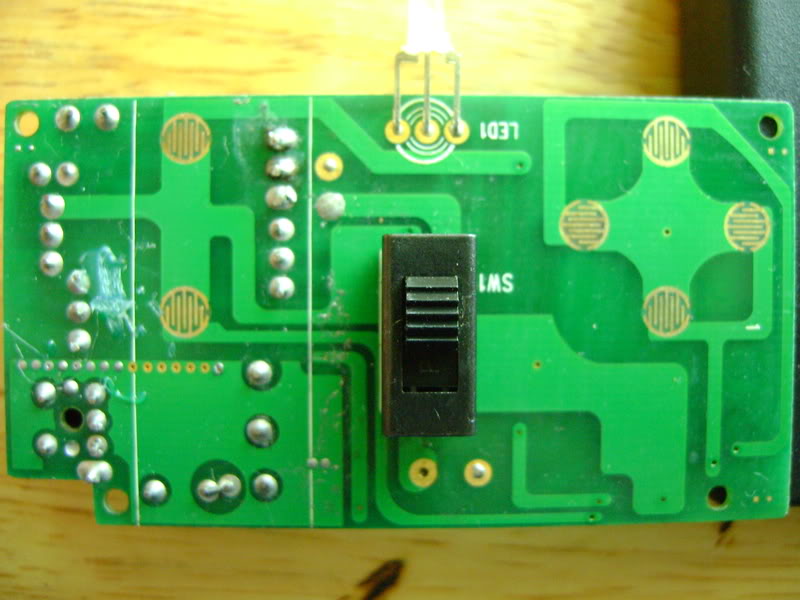

Flip the transmitter board over to locate the control pads. For this project, you will be using the control pads on the left hand side with 2 pads.

On the control pads, notice the subtle two halves of each circular contacts.

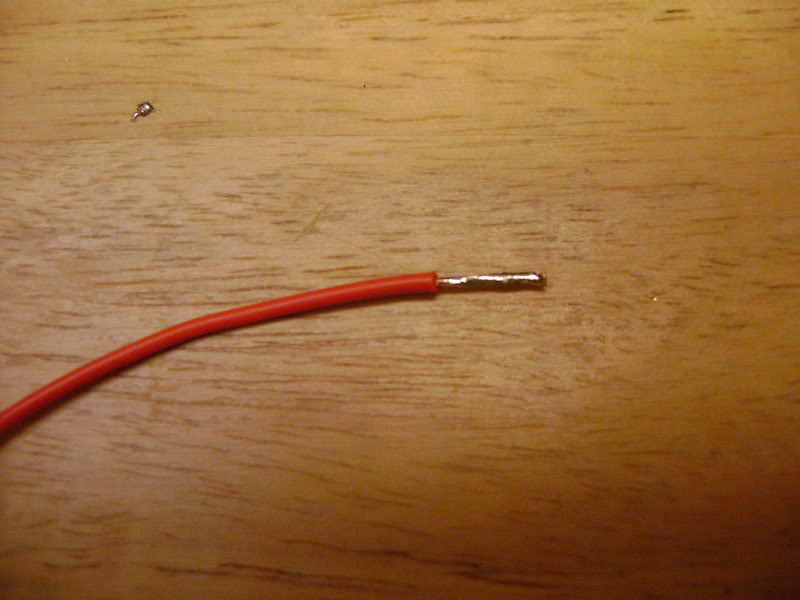

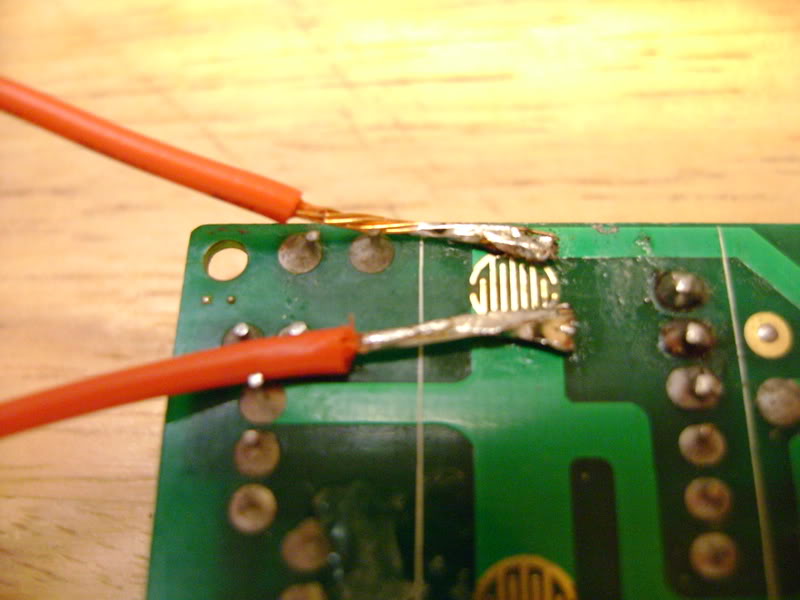

Pre-solder the wire leads before soldering to one half of controller pad contacts. Make sure you have just enough solder to cover the wire lead itself.

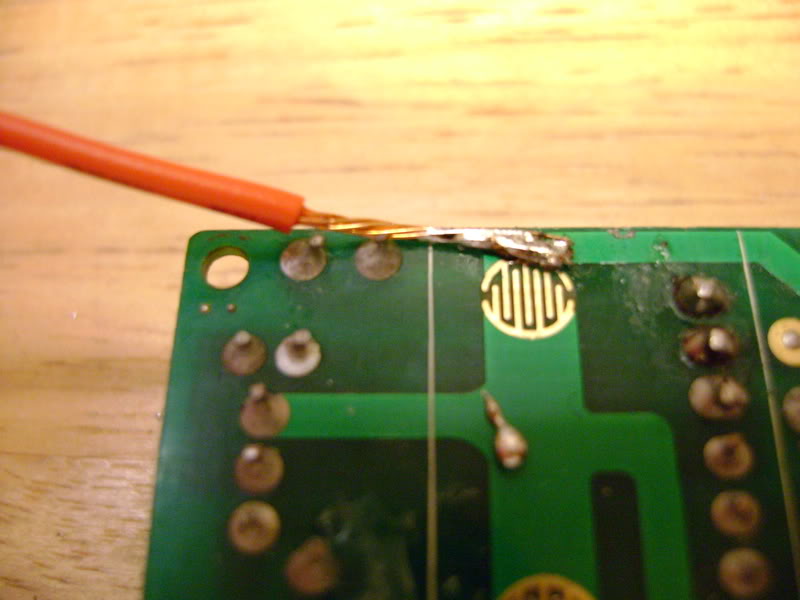

This is the real tricky part. Solder about 5 inches of wire to each half (the tip of the half circle) for a total of 4 strips of wire. Be very careful not to cross solder into the opposite half as this will short the circuit. Heat the wire lead long enough to melt the solder on the lead but just enough to make it stick to the contact's edge. This method will prevent cross soldering to the other half of the contact therefore, you will not see too much solder as you normally would.

This is how it should look after soldering the wires.

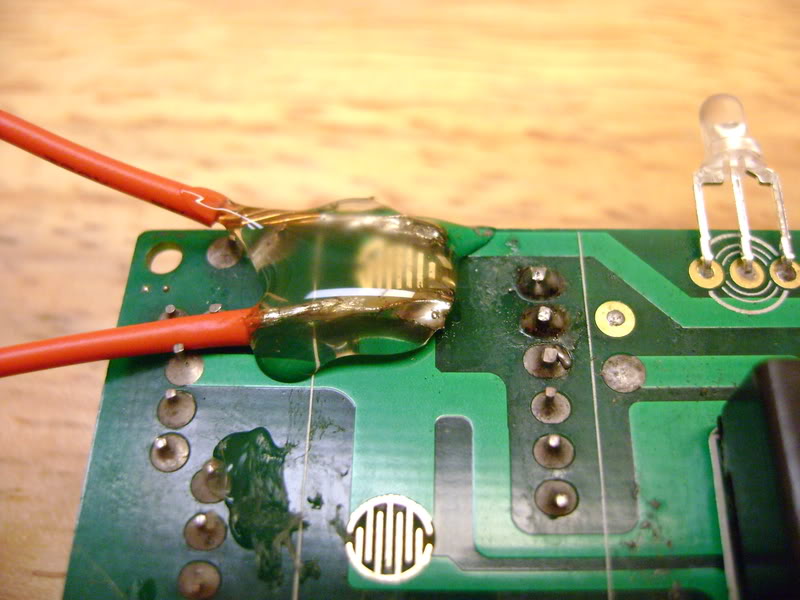

Hot glue the pads and the soldered wire leads to prevent them from breaking off.

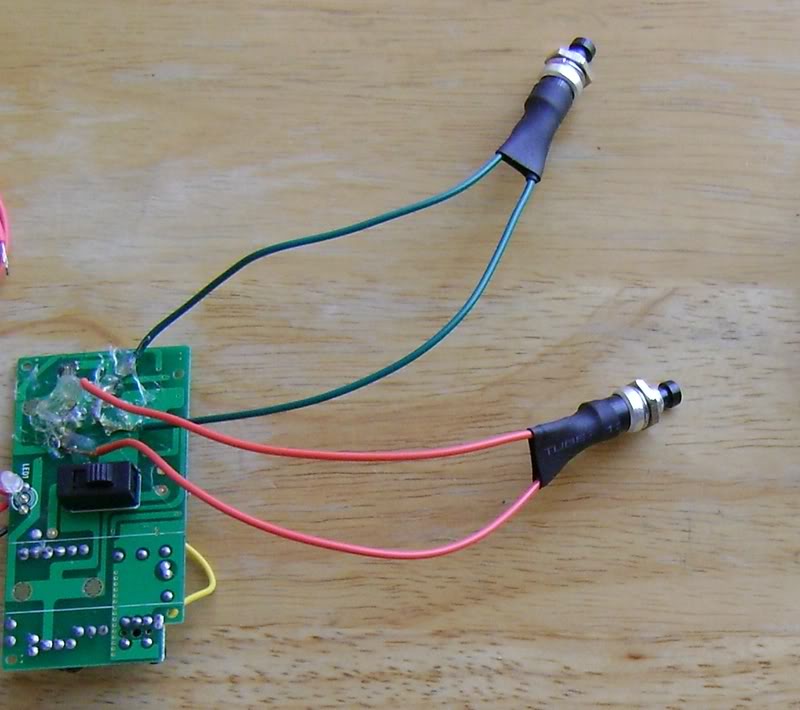

I know that in this picture I am using the right side controller pad but the concept is the same for the left controller pad. Slip 4 short strips of heatshrink tubing on each of the 4 wires on the control pads. Solder the exposed ends from the two wires coming from one control pad to leads of one SPST momentary switch. Heat the heatshrink tubing over the leads. Repeat for the other control pad wires.

End Of Step 1

Step 2: Open the car body to remove the receiver board from the chassis

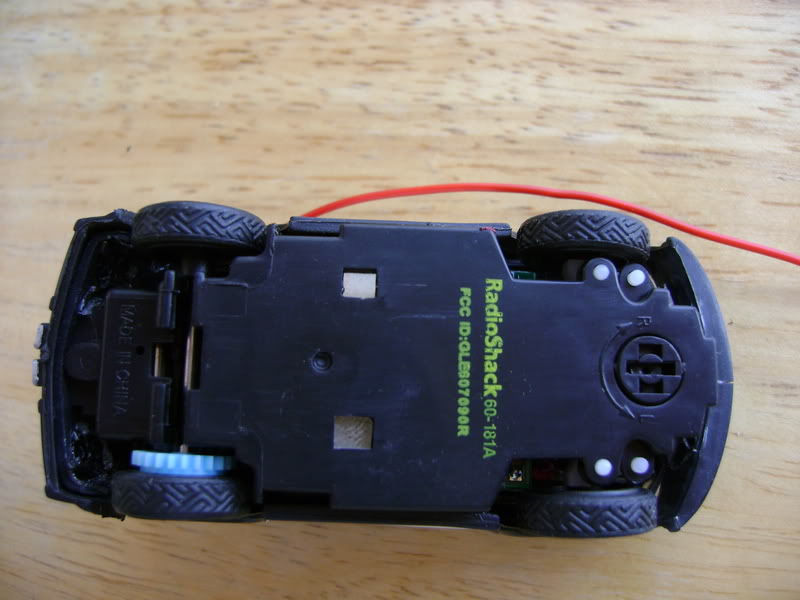

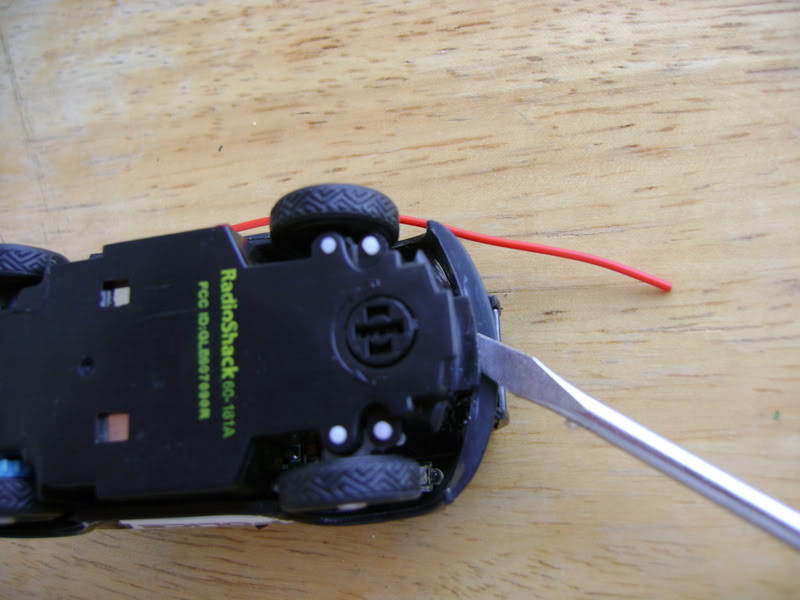

Here is the car body. Flip the car over and pry the front and back lock tab with a small screw driver.

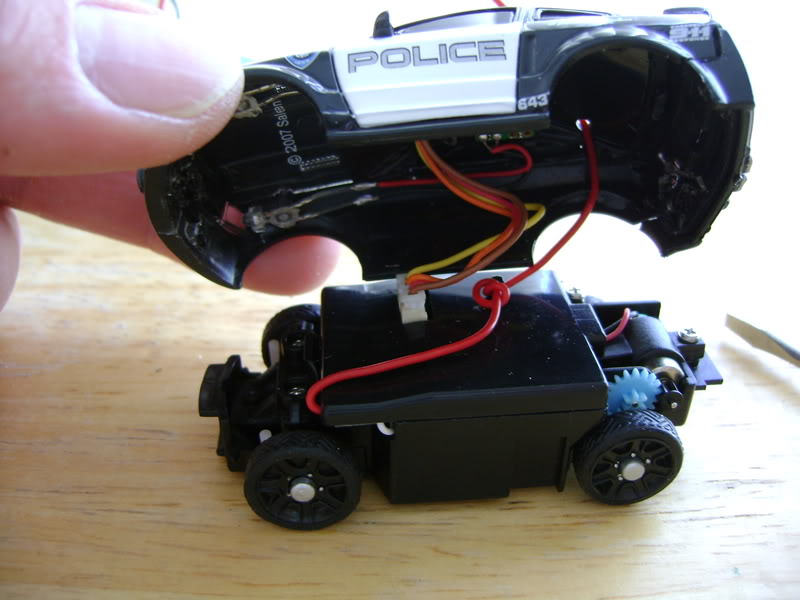

Now carefully pull the top off then you will see a connector for the car lights attached to the chassis. Carefully pull the connector off then slip the red antenna wire through the hole in the car top.

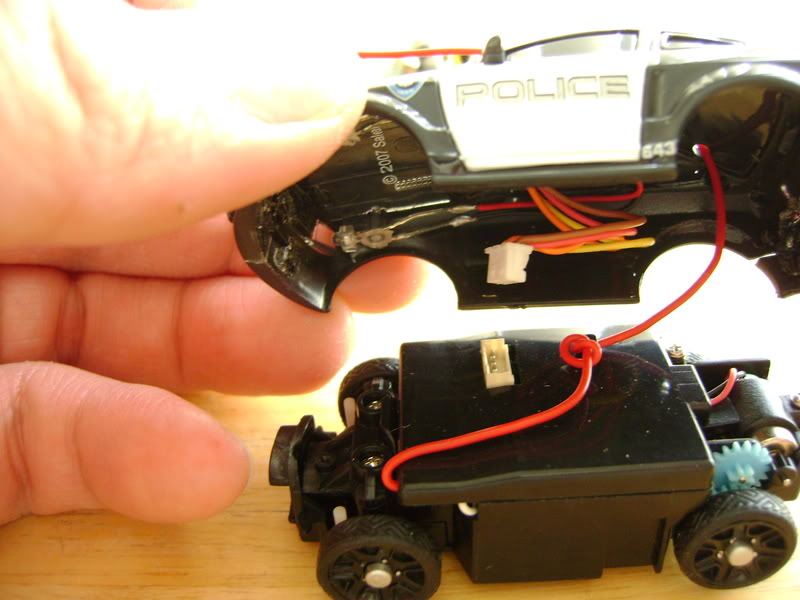

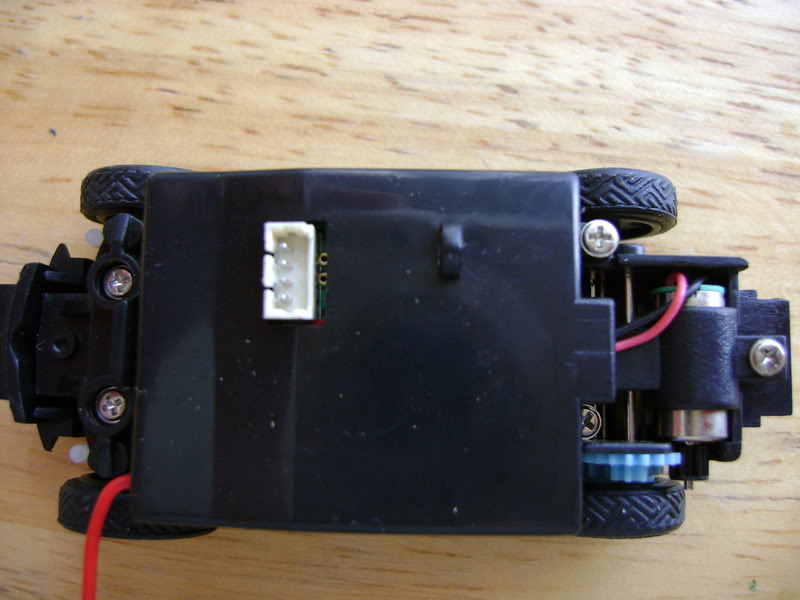

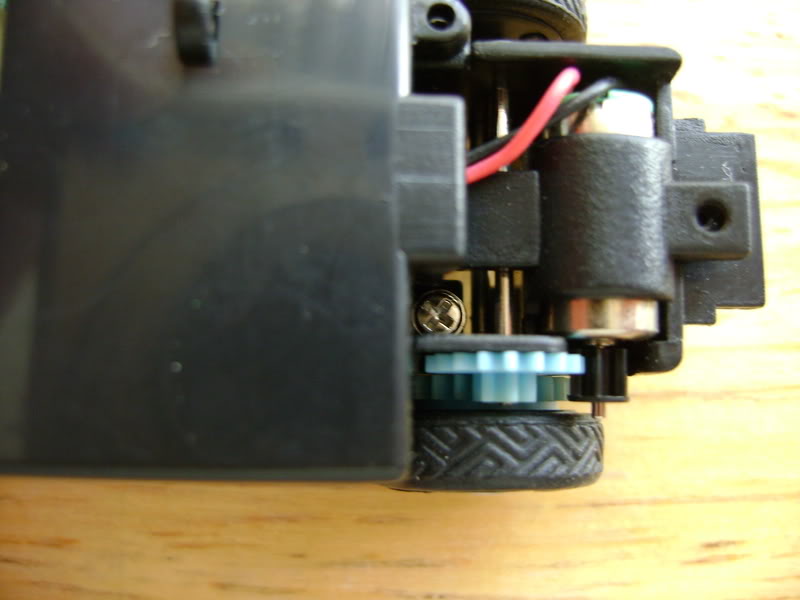

Next, remove five screws from the top of the chassis. The second picture below shows one screw in front of the motor compartment which is kinda hidden.

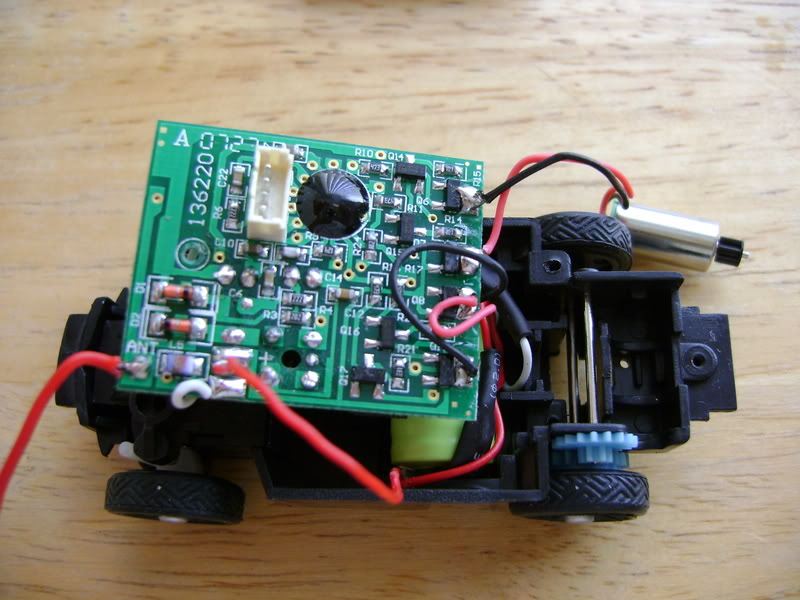

At this point, you should be able to pull the board of the chassis with a little bit jiggling some plastic parts to free it.

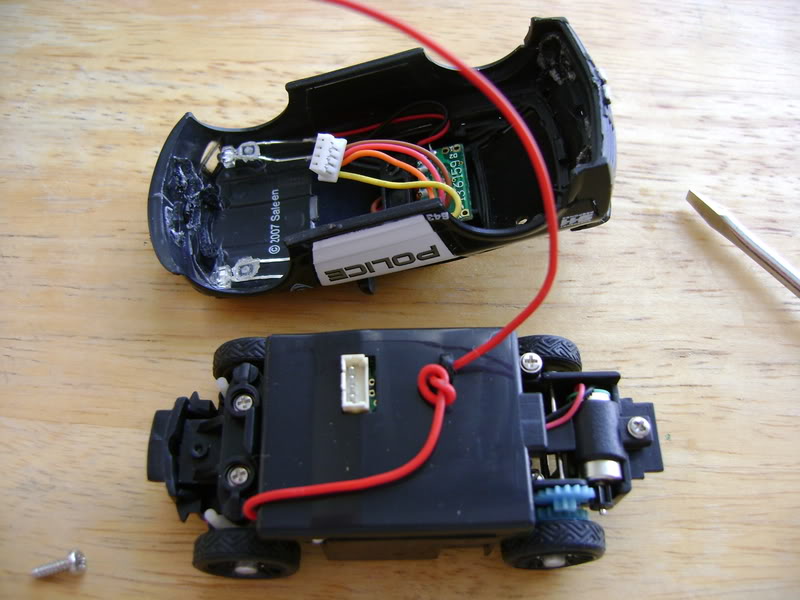

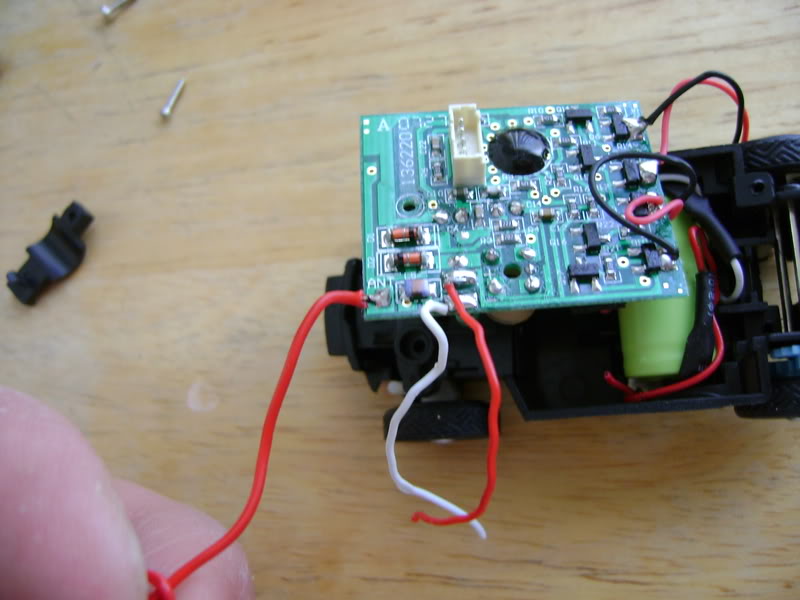

Cut the red and white wires from the light green capacitor in the chassis.

Then, cut the black and red wires connected to the steering motor.

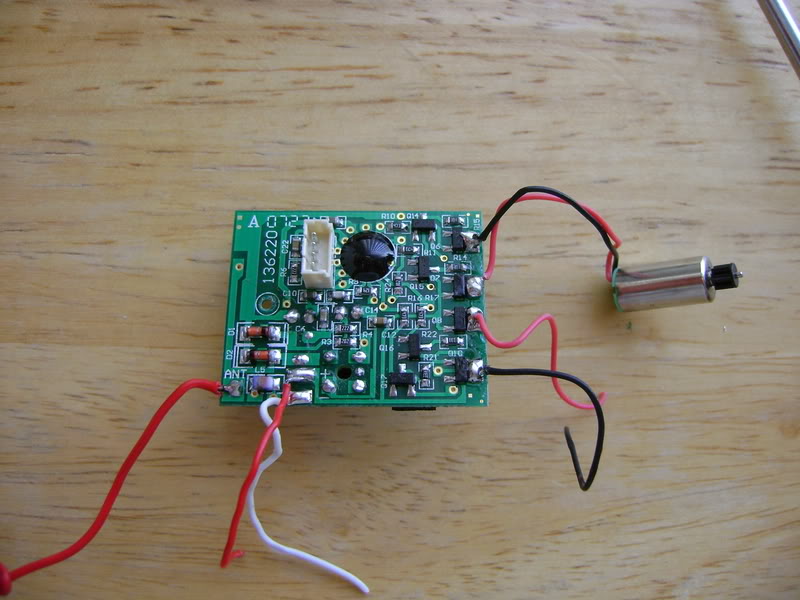

This is what you should have so far with the receiver board.

Now cut two short strips of heatshrink tubing and slip them on the power supply red and white wires on the receiver board. Strip and expose about 1/4" of wire at the loose end of the red and white wires.

Twist the exposed wire ends to the wires from one of the AAA battery box with a switch. Solder the wires and slip the heatshrink tubing over the exposed wires to protect them from shorting. Hot glue the red and white power supply wire leads and the motor red and black wires on the receiver board to protect it from breaking off.

Note: At this point, turn on the switches in the transmitter battery box and the receiver battery box. Then turn on the onboard switch on the transmitter board (Green LED light should come on). Press on one of the SPST switches and the test motor should spin one way. Press the other SPST switch and the test motor should spin the other way. Congratulations! You just passed your connectivity test!

End Of Step 2

Step 3: Tweaking the Hitec HS-77BB Low Profile Analog Servo

I used a low profile servo for a better helmet fit. Otherwise, your head might not fit inside the helmet with a regular size servo.

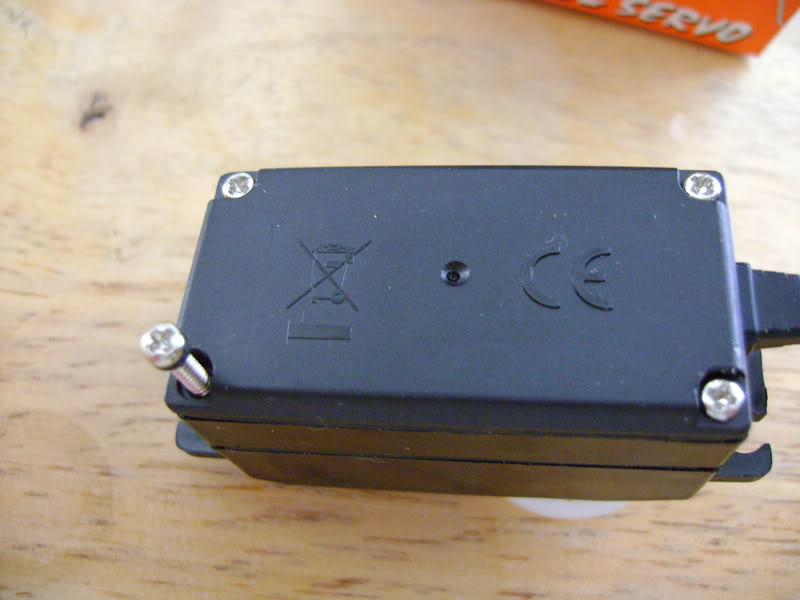

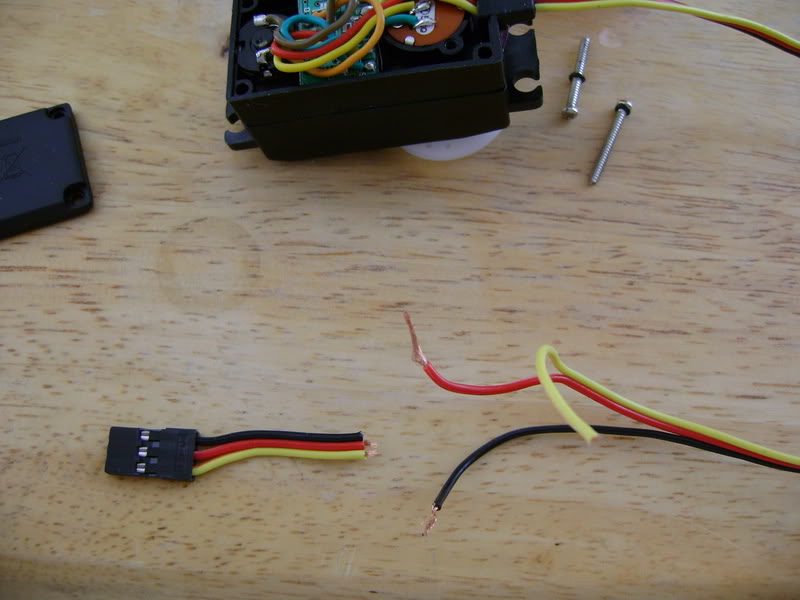

Flip the servo over and remove the 4 screws on the back panel.

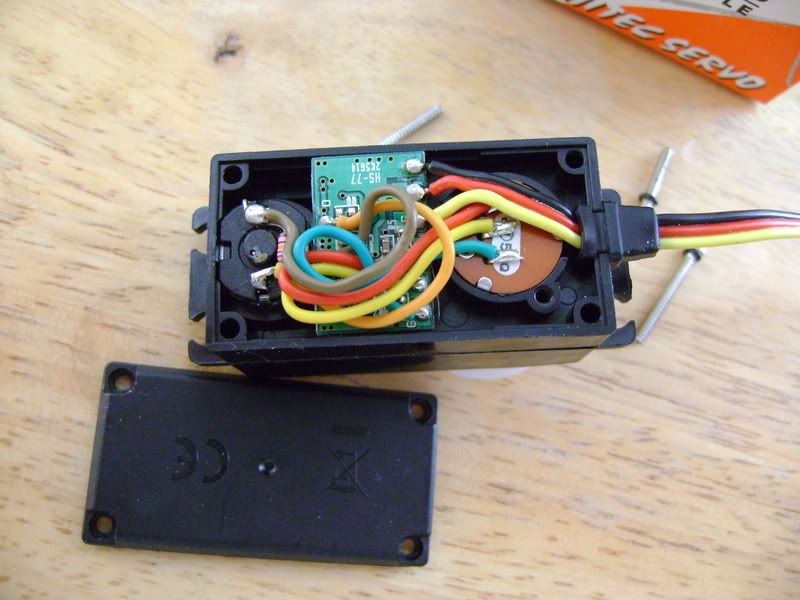

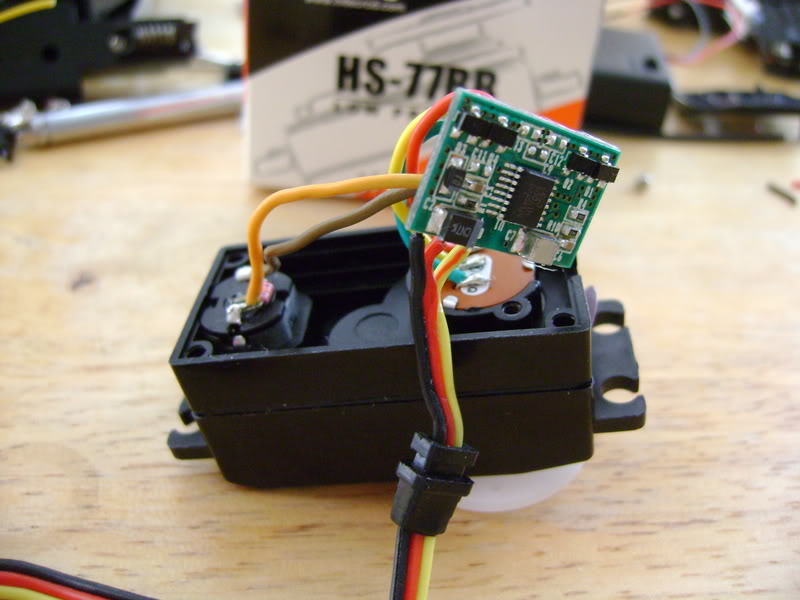

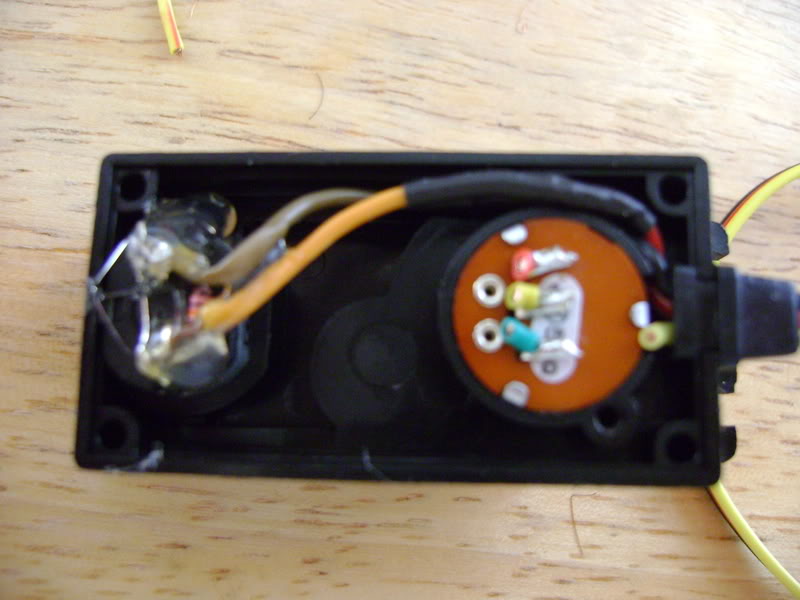

Here is the layout of the onboard servo controller board.

Now cut the yellow, red and green wires off the board. Then cut the yellow, red and black wires off the board. Lastly, cut the brown and yellow wires off the board.

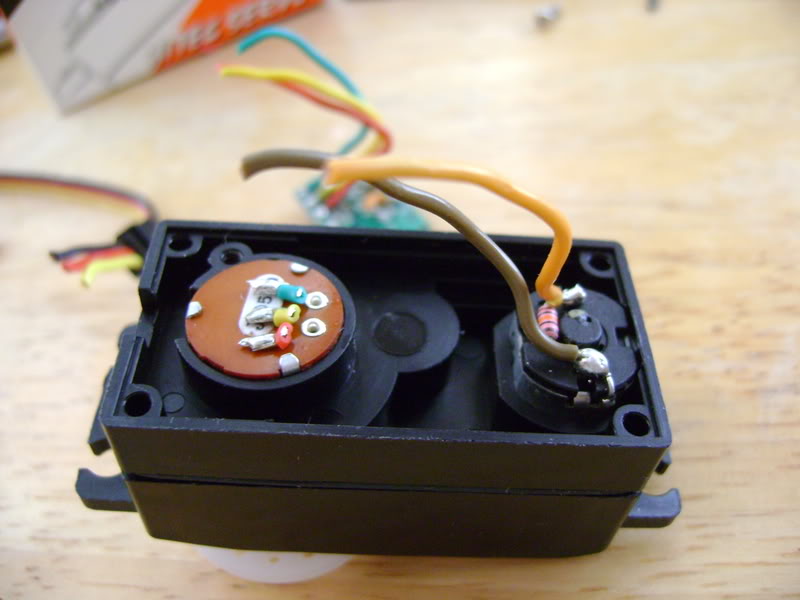

The brown and yellow wires are connected to the servo motor itself. These wires will be used later to connect to the receiver black and red wires.

Slip on two short strips of heatshrink tubing to the yellow and brown wires coming from the servo motor. Connect and then solder the servo (red, black and yellow wires) power wire to the servo motor yellow and brown wires by using only the red and black wires.

Hot glue the wire leads on the servo motor to prevent it from breaking off. This is where you should be at this point.

Screw the panel back onto the servo.

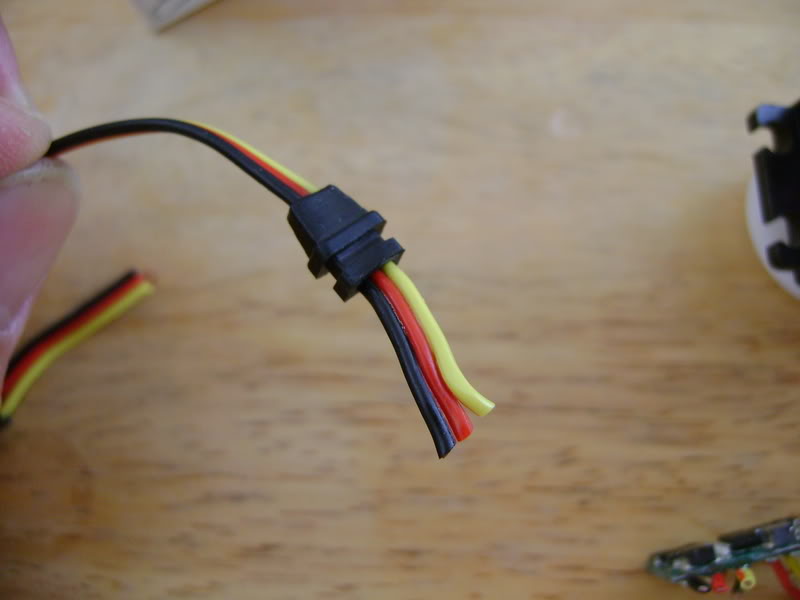

Now cut off the connector from the servo red, black and yellow power wire.

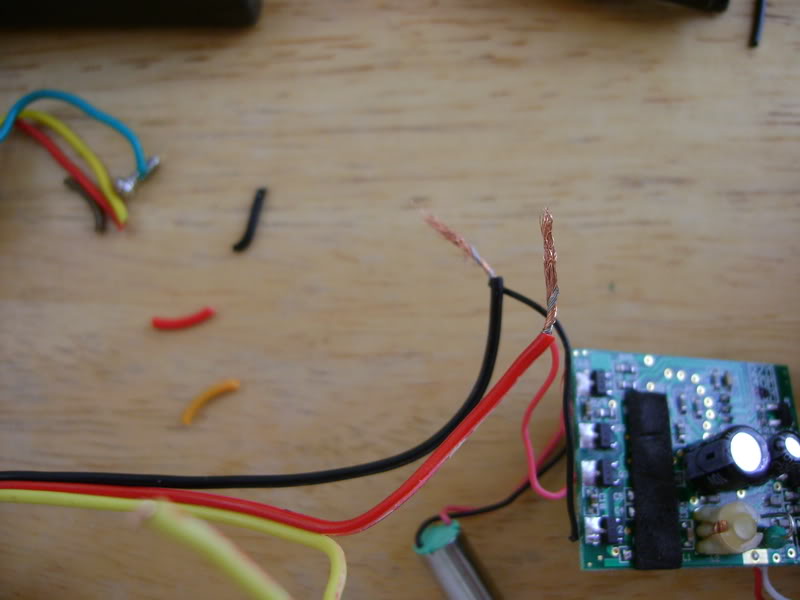

Cut off the test motor from the receiver board. Slip on two short strips of heatshrink tubing on the black and red wires from the test motor. Connect and solder the black and red wires from test motor to the servo red, black and yellow wire by using only the red and black wires.

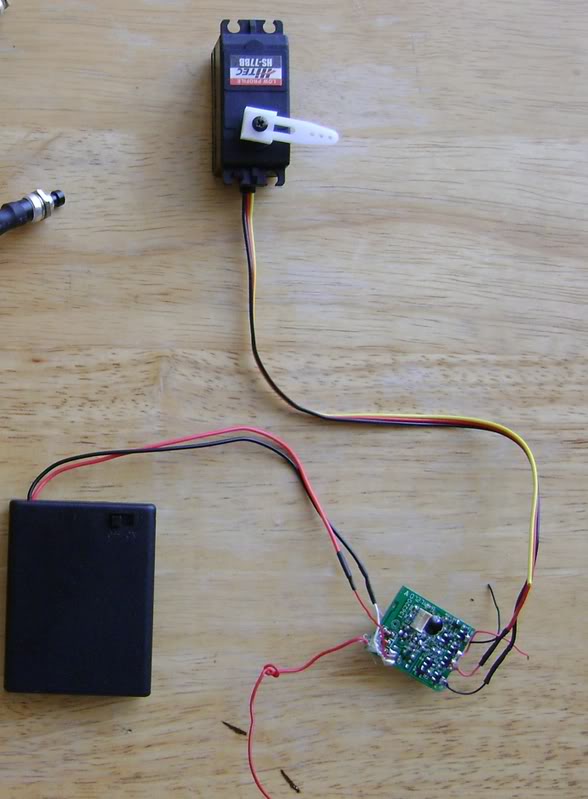

Slip the heatshrink tubing over the solder connections from the receiver board and the servo and apply heat with heat gun. The picture below is where you should be at this point.

Step 4: Servo Trial Run

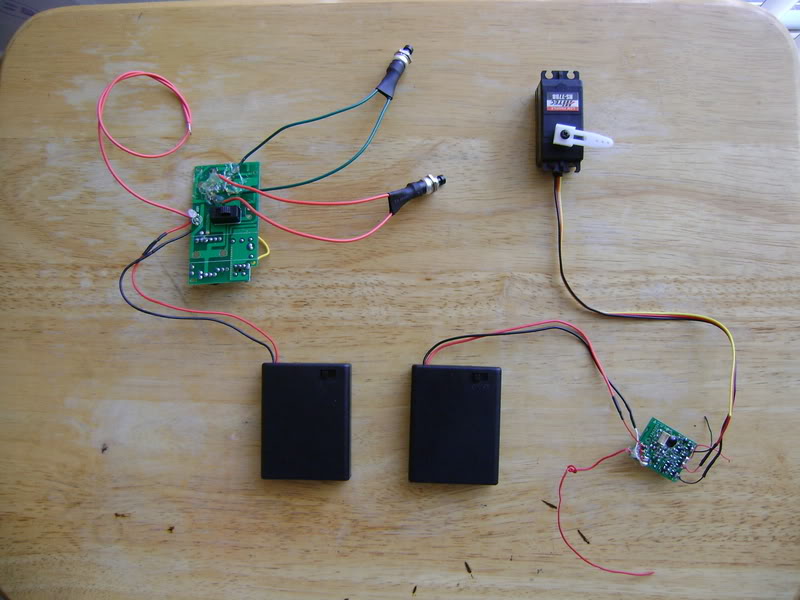

This is the RF actuator system as a whole minus the RF stalk and helmet. One switch will move the stalk down and the other will move it up. It’s up to you how you will install your servo in the helmet according to it’s movement. Once you see how the actuator moves, you will have a reference point on how you should place it in the helmet according to how the RF should behave.

End of Step 4.

Here is a clip of the servo in action

Step 5: Attaching the servo shaft attachment, RF stalk and servo unit into the helmet:

The servo shaft can be cut according to the thickness of the particular helmet you are using. You'd want to have just enough length for the stalk to attach to. I had to cut mine just about halfway down so that it will be flushed with the thickness of the RF stalk. Cut the screw a bit longer than the shaft coz it has to thread into the servo spline to hold the shaft in.

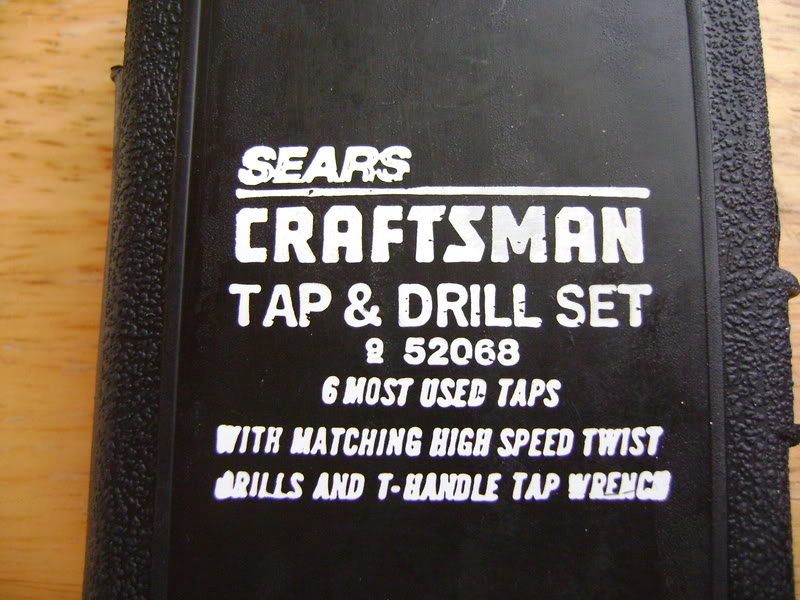

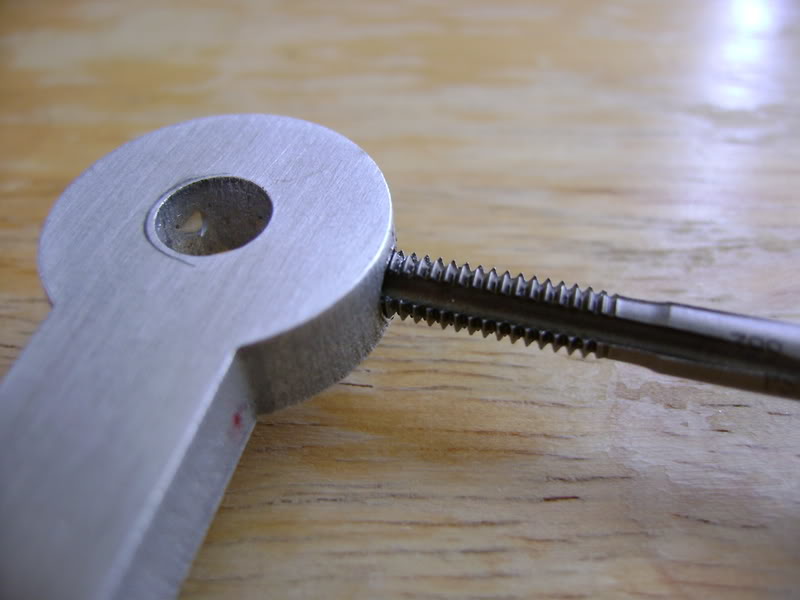

For the RF stalk, I have a BKBT aluminum stalk in which I drilled an 8-32 size hole using a Craftsman Tap & Drill set.

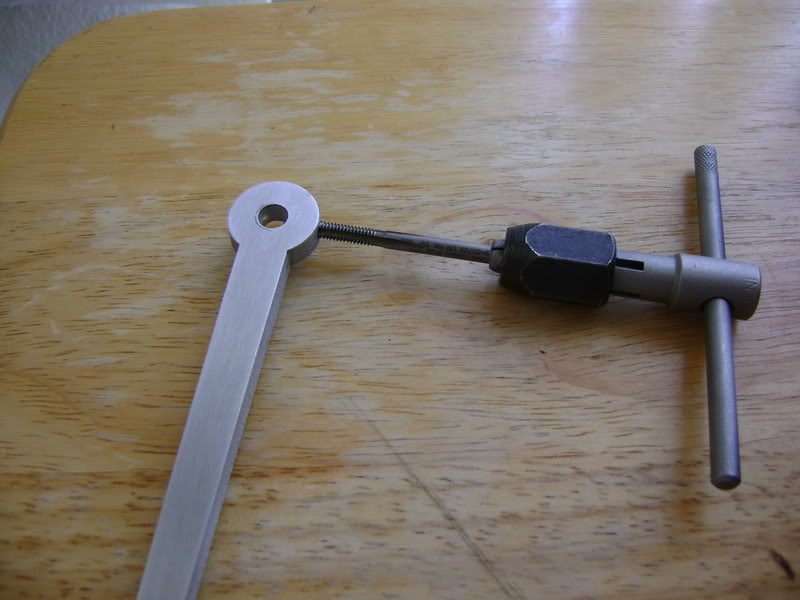

Then I used the tap to cut 8-32 size threads into the hole on the stalk. The position of hole is at the top of the rounded end of the stalk when it's in the down position. This way, the hole is not seen while its in the up position.

Then I got some size 8-32 x 5/16 socket head set screws from Lowes that can be tightened with an allen wrench. Using this method of attachment, the stalk can be removed when stowing the helmet away.

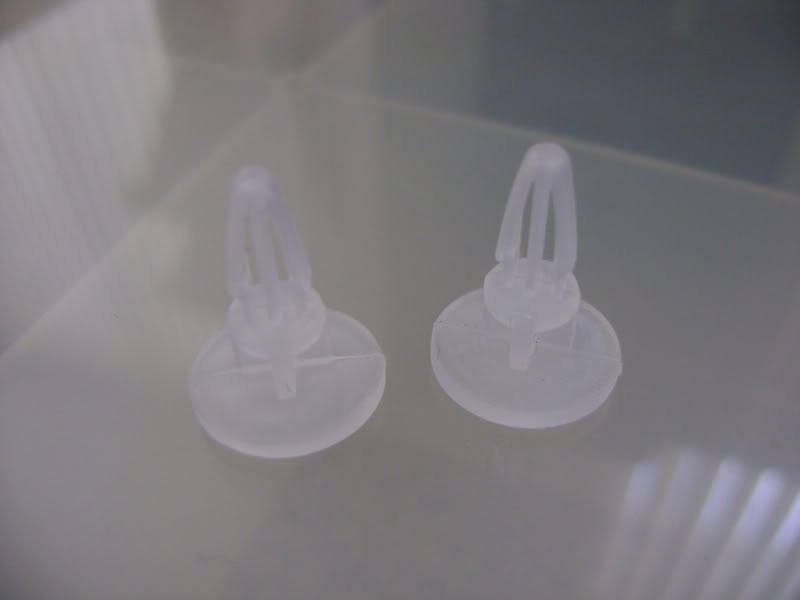

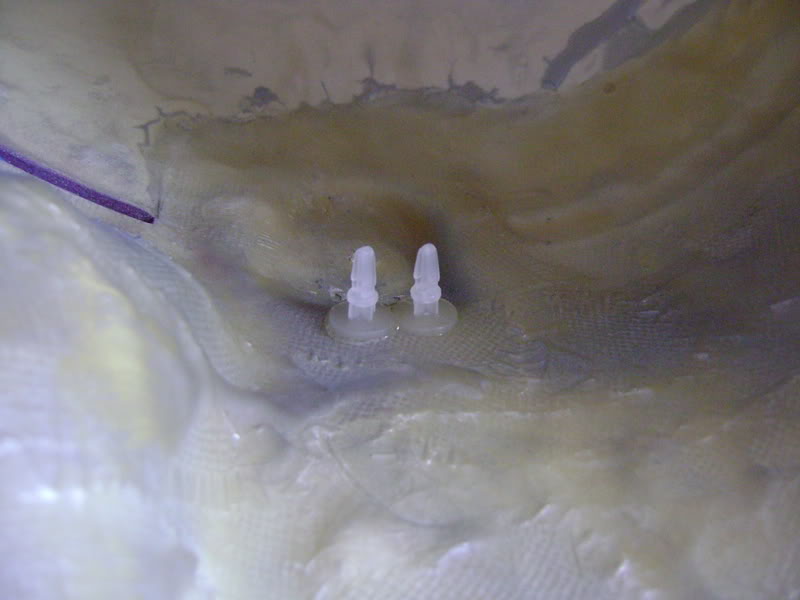

To attach the servo unit to the helmet, I used two plastic computer case motherboard fasteners hot glued to the helmet. The servo attachment holes just slides in and snaps into place and is easily removed by sliding it out.

Notice how I positioned the servo unit in the helmet.

This is how it looks with the shaft attachment.

I positioned the shaft in the down position so I can tighten the screw in place.

This is how the RF stalk should work installed in the helmet.

FINISHED HELMET WITH RF ACTUATOR INSTALLED IN HELMET AND LEFT GAUNTLET.

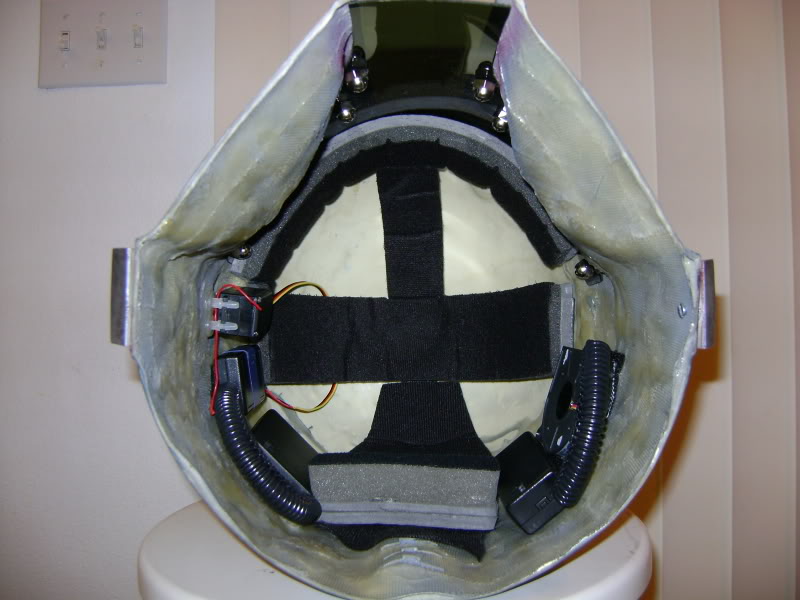

Here is the underside of the helmet showing the RF actuator receiver assembly on the left side and the helmet squirrel/blower fan on the right.

LEFT GAUNTLET WITH ZIP ZAP TRANSMITTER BOARD AND SWITCHES

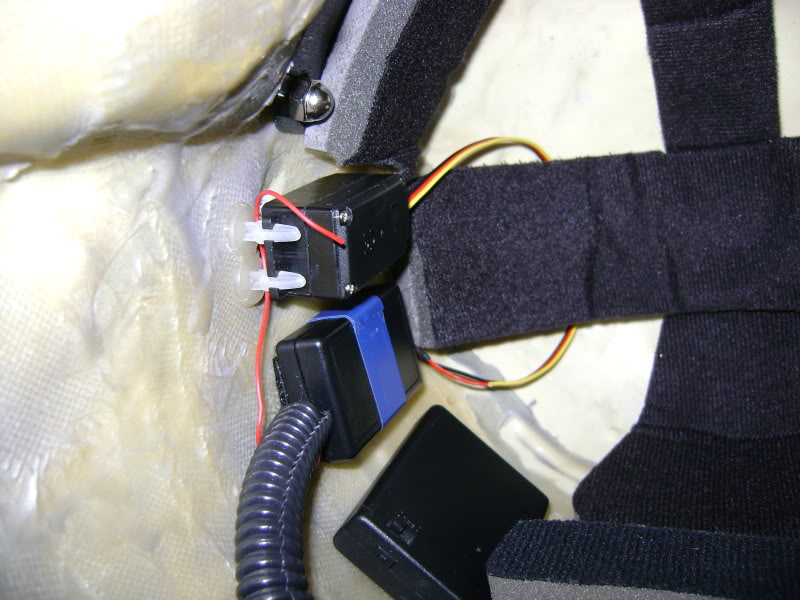

Here is the inside/underside of the gaunt showing the transmitter board, SPST switches, battery boxes for the transmitter and the red LED light on the side of the left gaunt.

Here is a clip of the RF system activated.

Here is the tutorial for the Radio Shack Zip Zap mini RC.

Here are the materials you will need to complete this project:

- 1 Radio Shack Zip Zap Mini RC

- 2 4 Cell AAA Battery Boxes with switches

- 1 Hitec HS-77BB Low Profile Analog Servo

- 1 Package of Radio Shack Mini SPST Switches # 275-1547

- 1 Pack of Heat Shrink Tubing

- 1 Heat Gun

- 1 Cold Heat or soldering iron/gun

- Some solder

- 1 Hot Glue Gun

Flip the RC unit over and remove the screws from the back panel.

Pull the panel off carefully as not to pull the leads off the board.

Here you can see the red and black power supply wires going to the board

Follow the power supply wires to the battery compartment in the back panel

Cut the red and black wires on the battery compartment in the back panel

Here you can see the yellow and black wires for the charger unit. Cut them down to the board as it will not be needed for this project. The charger unit pops right off the top then put it aside.

Here you can see the transmitter antenna and wire. Remove the screw that attaches the yellow wire to the base of the antenna post.

Here you can see 4 board screws, remove them and pull the board off the front panel

Hot glue the power supply black and red wire leads to the board to prevent them from breaking off.

Slip on two short strips of heatshrink tubing on the power supply black and red wires then twist the exposed ends with wires from the AAA battery box with a switch. Solder the twisted wire ends then slip the heatshrink tubing over the soldered ends and heat with heat gun.

Flip the transmitter board over to locate the control pads. For this project, you will be using the control pads on the left hand side with 2 pads.

On the control pads, notice the subtle two halves of each circular contacts.

Pre-solder the wire leads before soldering to one half of controller pad contacts. Make sure you have just enough solder to cover the wire lead itself.

This is the real tricky part. Solder about 5 inches of wire to each half (the tip of the half circle) for a total of 4 strips of wire. Be very careful not to cross solder into the opposite half as this will short the circuit. Heat the wire lead long enough to melt the solder on the lead but just enough to make it stick to the contact's edge. This method will prevent cross soldering to the other half of the contact therefore, you will not see too much solder as you normally would.

This is how it should look after soldering the wires.

Hot glue the pads and the soldered wire leads to prevent them from breaking off.

I know that in this picture I am using the right side controller pad but the concept is the same for the left controller pad. Slip 4 short strips of heatshrink tubing on each of the 4 wires on the control pads. Solder the exposed ends from the two wires coming from one control pad to leads of one SPST momentary switch. Heat the heatshrink tubing over the leads. Repeat for the other control pad wires.

End Of Step 1

Step 2: Open the car body to remove the receiver board from the chassis

Here is the car body. Flip the car over and pry the front and back lock tab with a small screw driver.

Now carefully pull the top off then you will see a connector for the car lights attached to the chassis. Carefully pull the connector off then slip the red antenna wire through the hole in the car top.

Next, remove five screws from the top of the chassis. The second picture below shows one screw in front of the motor compartment which is kinda hidden.

At this point, you should be able to pull the board of the chassis with a little bit jiggling some plastic parts to free it.

Cut the red and white wires from the light green capacitor in the chassis.

Then, cut the black and red wires connected to the steering motor.

This is what you should have so far with the receiver board.

Now cut two short strips of heatshrink tubing and slip them on the power supply red and white wires on the receiver board. Strip and expose about 1/4" of wire at the loose end of the red and white wires.

Twist the exposed wire ends to the wires from one of the AAA battery box with a switch. Solder the wires and slip the heatshrink tubing over the exposed wires to protect them from shorting. Hot glue the red and white power supply wire leads and the motor red and black wires on the receiver board to protect it from breaking off.

Note: At this point, turn on the switches in the transmitter battery box and the receiver battery box. Then turn on the onboard switch on the transmitter board (Green LED light should come on). Press on one of the SPST switches and the test motor should spin one way. Press the other SPST switch and the test motor should spin the other way. Congratulations! You just passed your connectivity test!

End Of Step 2

Step 3: Tweaking the Hitec HS-77BB Low Profile Analog Servo

I used a low profile servo for a better helmet fit. Otherwise, your head might not fit inside the helmet with a regular size servo.

Flip the servo over and remove the 4 screws on the back panel.

Here is the layout of the onboard servo controller board.

Now cut the yellow, red and green wires off the board. Then cut the yellow, red and black wires off the board. Lastly, cut the brown and yellow wires off the board.

The brown and yellow wires are connected to the servo motor itself. These wires will be used later to connect to the receiver black and red wires.

Slip on two short strips of heatshrink tubing to the yellow and brown wires coming from the servo motor. Connect and then solder the servo (red, black and yellow wires) power wire to the servo motor yellow and brown wires by using only the red and black wires.

Hot glue the wire leads on the servo motor to prevent it from breaking off. This is where you should be at this point.

Screw the panel back onto the servo.

Now cut off the connector from the servo red, black and yellow power wire.

Cut off the test motor from the receiver board. Slip on two short strips of heatshrink tubing on the black and red wires from the test motor. Connect and solder the black and red wires from test motor to the servo red, black and yellow wire by using only the red and black wires.

Slip the heatshrink tubing over the solder connections from the receiver board and the servo and apply heat with heat gun. The picture below is where you should be at this point.

Step 4: Servo Trial Run

This is the RF actuator system as a whole minus the RF stalk and helmet. One switch will move the stalk down and the other will move it up. It’s up to you how you will install your servo in the helmet according to it’s movement. Once you see how the actuator moves, you will have a reference point on how you should place it in the helmet according to how the RF should behave.

End of Step 4.

Here is a clip of the servo in action

Step 5: Attaching the servo shaft attachment, RF stalk and servo unit into the helmet:

The servo shaft can be cut according to the thickness of the particular helmet you are using. You'd want to have just enough length for the stalk to attach to. I had to cut mine just about halfway down so that it will be flushed with the thickness of the RF stalk. Cut the screw a bit longer than the shaft coz it has to thread into the servo spline to hold the shaft in.

For the RF stalk, I have a BKBT aluminum stalk in which I drilled an 8-32 size hole using a Craftsman Tap & Drill set.

Then I used the tap to cut 8-32 size threads into the hole on the stalk. The position of hole is at the top of the rounded end of the stalk when it's in the down position. This way, the hole is not seen while its in the up position.

Then I got some size 8-32 x 5/16 socket head set screws from Lowes that can be tightened with an allen wrench. Using this method of attachment, the stalk can be removed when stowing the helmet away.

To attach the servo unit to the helmet, I used two plastic computer case motherboard fasteners hot glued to the helmet. The servo attachment holes just slides in and snaps into place and is easily removed by sliding it out.

Notice how I positioned the servo unit in the helmet.

This is how it looks with the shaft attachment.

I positioned the shaft in the down position so I can tighten the screw in place.

This is how the RF stalk should work installed in the helmet.

FINISHED HELMET WITH RF ACTUATOR INSTALLED IN HELMET AND LEFT GAUNTLET.

Here is the underside of the helmet showing the RF actuator receiver assembly on the left side and the helmet squirrel/blower fan on the right.

LEFT GAUNTLET WITH ZIP ZAP TRANSMITTER BOARD AND SWITCHES

Here is the inside/underside of the gaunt showing the transmitter board, SPST switches, battery boxes for the transmitter and the red LED light on the side of the left gaunt.

Here is a clip of the RF system activated.

Last edited by a moderator: