Allrighty... Now that I have done several ESBs for folks here and my self... I think its time to try something new. I am currently working on finishing up my ROTJ costume and wanted to attempt the best possible ROTJ bucket I could. Of course just doing mine would be to simple right  well I took on good ol' Ripcodes as well.

well I took on good ol' Ripcodes as well.

Heres the stats!

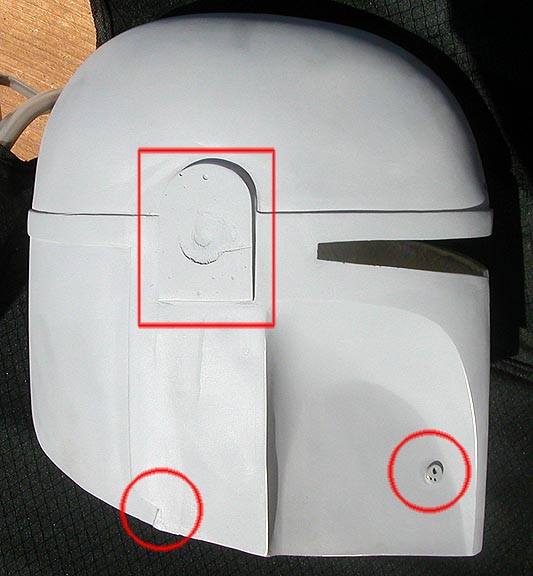

Good condition MS1 bucket with MS3 Coldcast earcap kit, BKBT metal stalk, and MS Keyhole replacement kit. One would think I had my work cut out for me!

What I hope to accomplish with his bucket:

1. Thining the thickness of where the visor meets the mandables to be more screen accurate.

2. Add an actual Molar Connector (Ripcode did this before he sent his bucket to me)

3. Fix all divits, pin holes, and chips with bondo

4. Fix the angle at the botom of both sides of the ears to be screen accurate

5. Remove the keyholes that came on the bucket and add the MS Keyholes with MQ-1 circut board in it

6. Add all accurate scrapes and goudges in the helmet as seen in the MOM exibit.

7. Fill all the crevises and holes at the bottom edge of the helmet

8. Fix the triangles on the forhead to be strait and correct.

9. Adapt the right side for the Cold cast MS Kit and add the slightly raised area that is seen on the screen used helmet (like the MS2 has)

10. Use magnet system in the Earcap for easy transportation of helmet in case

Okay... now here are my pics of where I am at so far.

THe pics showing the helmet unprimed show it as it came to me.

I then show a slightly primed bucket (I prime my buckets to highlight pinholes and inperfections to fix with bodo) and lastly the "Where I am at" pics off a primed and wetsanded bucket. I still have a few tweeks minus the ear caps and a few gouges before I can start to paint. I will disclose my custom mix and strait form bottle color list as I choose it.

Heres the stats!

Good condition MS1 bucket with MS3 Coldcast earcap kit, BKBT metal stalk, and MS Keyhole replacement kit. One would think I had my work cut out for me!

What I hope to accomplish with his bucket:

1. Thining the thickness of where the visor meets the mandables to be more screen accurate.

2. Add an actual Molar Connector (Ripcode did this before he sent his bucket to me)

3. Fix all divits, pin holes, and chips with bondo

4. Fix the angle at the botom of both sides of the ears to be screen accurate

5. Remove the keyholes that came on the bucket and add the MS Keyholes with MQ-1 circut board in it

6. Add all accurate scrapes and goudges in the helmet as seen in the MOM exibit.

7. Fill all the crevises and holes at the bottom edge of the helmet

8. Fix the triangles on the forhead to be strait and correct.

9. Adapt the right side for the Cold cast MS Kit and add the slightly raised area that is seen on the screen used helmet (like the MS2 has)

10. Use magnet system in the Earcap for easy transportation of helmet in case

Okay... now here are my pics of where I am at so far.

THe pics showing the helmet unprimed show it as it came to me.

I then show a slightly primed bucket (I prime my buckets to highlight pinholes and inperfections to fix with bodo) and lastly the "Where I am at" pics off a primed and wetsanded bucket. I still have a few tweeks minus the ear caps and a few gouges before I can start to paint. I will disclose my custom mix and strait form bottle color list as I choose it.