QuartZ

New Hunter

Hello!

Wow, I've been gone so long that my account didn't exist anymore. In truth, I've been away from prop replica building for a while as well but I've slowly made my way back in the last few years. It feels great. So rather than blabber any more about that, I wanted to share a build I recently started (I hope I finish it... you know). But even if I don't, I hope some of the information or images help or inspire someone else.

I wanted to build a Fett ESB EE-3 blaster and so I started by looking around at my Webley base options. My goal is to have something that looks really authentic/accurate but I'm not looking to use found parts or spend much money on this. Also, I'm going to be making it out of a variety of materials/methods and using part offerings from others on this forum whenever it helps with the goals I just mentioned. I've also gotten really into using 3D printing in my recent projects so it made sense to look for an accurate model to use. I found the great model by RafalFett and after comparing other options decided that was the right base for me. So I got to slicing and printing. I printed the "metal" parts in grey PLA:

And here's a quick test fit of the main parts:

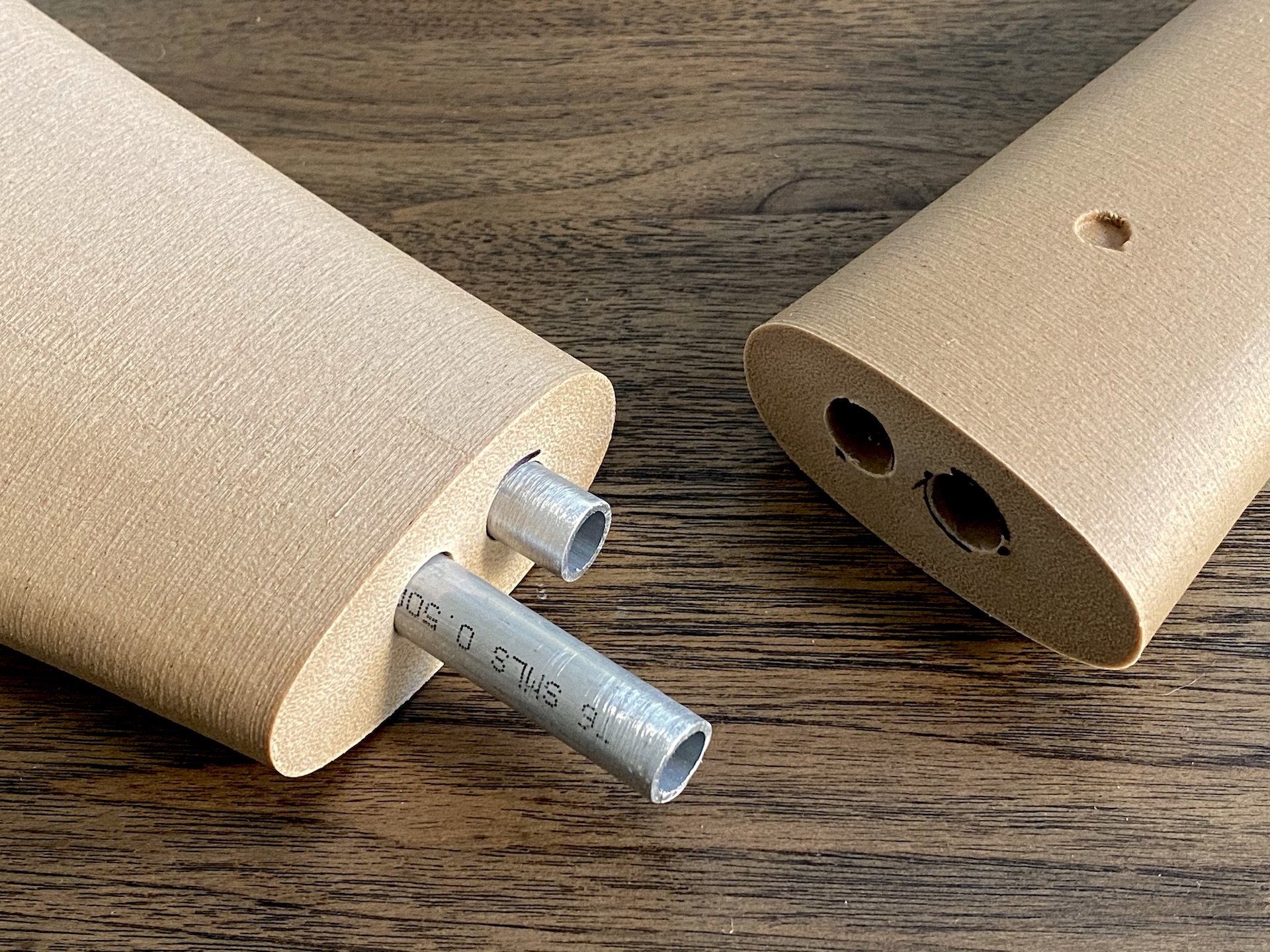

I wanted to try something different with the stock. I know I'll end up painting all the parts in the end, but I wanted to try working with Fillamentum Timberfill as it has wood fibers in the plastic. I don't know if it will make ANY difference, but it was fun to try and I already had it sitting around. The stock is too big for my printer (a Prusa i3 MK2.5S) so I brought the stock STL into mesh mixer and split it. While I was there, I also added to 1/2" holes to insert an aluminum tube for some additional reinforcement and a shorter piece of aluminum tube to act as an alignment "key" when assembling the halves.

The alignment looks good. There's a little bit of a raised lip at the joint or "elephants foot" from the mating surfaces being the area that was on the bed of the printer. Should be easy enough to sand away. Feels really strong and has a good heft to it so I'm happy.

Next, I put everything together for a test fit. Nothing is glued at this point and I've used various tricks like dowels wrapped in blue painters tape to create snug temporary pins/hardware. Also, you'll see me using painters tape to lash the pistole grip frame to the stock bracket. It was nice to be able to handle the whole flare gun after a few days of printing.

I wanted to get an idea of how much the whole thing weighed. I'd like for it to be heavy enough to not feel hollow or toy-like, but I'd also be happy if it didn't feel like a tank. I managed to weigh it on a food scale and at this point we hit 650 g (just under 1.5 lbs). Pretty light so far... but I'm missing the revolver grip which I plan to make myself in cold-cast brass/resin. That will add a little, then there's all of the metal hardware that's missing like screws, metal dowel pins, sling mounts, etc. I'd like to hit around 2 lbs with just the Webley (I know that's like 1/4 of the real item weight). I may replace the longer aluminum tube in the stock with a solid aluminum rod and I have thought about a thin metal tube to sleeve the interior of the 3D printed barrel that could help add some strength/weight there. In this state, it does feel pretty good to me. So I'll keep my options open and try some things.

So that's my start. Let me know if anything wasn't clear or if you have any questions. Again, huge thank you to RafalFett for the superb model!

-Dana

Wow, I've been gone so long that my account didn't exist anymore. In truth, I've been away from prop replica building for a while as well but I've slowly made my way back in the last few years. It feels great. So rather than blabber any more about that, I wanted to share a build I recently started (I hope I finish it... you know). But even if I don't, I hope some of the information or images help or inspire someone else.

I wanted to build a Fett ESB EE-3 blaster and so I started by looking around at my Webley base options. My goal is to have something that looks really authentic/accurate but I'm not looking to use found parts or spend much money on this. Also, I'm going to be making it out of a variety of materials/methods and using part offerings from others on this forum whenever it helps with the goals I just mentioned. I've also gotten really into using 3D printing in my recent projects so it made sense to look for an accurate model to use. I found the great model by RafalFett and after comparing other options decided that was the right base for me. So I got to slicing and printing. I printed the "metal" parts in grey PLA:

And here's a quick test fit of the main parts:

I wanted to try something different with the stock. I know I'll end up painting all the parts in the end, but I wanted to try working with Fillamentum Timberfill as it has wood fibers in the plastic. I don't know if it will make ANY difference, but it was fun to try and I already had it sitting around. The stock is too big for my printer (a Prusa i3 MK2.5S) so I brought the stock STL into mesh mixer and split it. While I was there, I also added to 1/2" holes to insert an aluminum tube for some additional reinforcement and a shorter piece of aluminum tube to act as an alignment "key" when assembling the halves.

The alignment looks good. There's a little bit of a raised lip at the joint or "elephants foot" from the mating surfaces being the area that was on the bed of the printer. Should be easy enough to sand away. Feels really strong and has a good heft to it so I'm happy.

Next, I put everything together for a test fit. Nothing is glued at this point and I've used various tricks like dowels wrapped in blue painters tape to create snug temporary pins/hardware. Also, you'll see me using painters tape to lash the pistole grip frame to the stock bracket. It was nice to be able to handle the whole flare gun after a few days of printing.

I wanted to get an idea of how much the whole thing weighed. I'd like for it to be heavy enough to not feel hollow or toy-like, but I'd also be happy if it didn't feel like a tank. I managed to weigh it on a food scale and at this point we hit 650 g (just under 1.5 lbs). Pretty light so far... but I'm missing the revolver grip which I plan to make myself in cold-cast brass/resin. That will add a little, then there's all of the metal hardware that's missing like screws, metal dowel pins, sling mounts, etc. I'd like to hit around 2 lbs with just the Webley (I know that's like 1/4 of the real item weight). I may replace the longer aluminum tube in the stock with a solid aluminum rod and I have thought about a thin metal tube to sleeve the interior of the 3D printed barrel that could help add some strength/weight there. In this state, it does feel pretty good to me. So I'll keep my options open and try some things.

So that's my start. Let me know if anything wasn't clear or if you have any questions. Again, huge thank you to RafalFett for the superb model!

-Dana