QuartZ

New Hunter

Slow and steady, I have another minor update that took me quite some time and effort. I have been meaning to get a resin 3D printer to supplement my FDM printer for a long time. The hammer on this prop was my excuse to finally dive in and get one. It's not that I didn't get a good part with the FDM print, but I really was after the texture on the hammer. So here's how it came out:

You can definitely see that the checkered area came out clean and crisp. However, the resin printer also exposed the low-polygon nature of other areas of the model (particularly some curved surfaces). No worries, that's easily fixed with some sanding and it's a much simpler issue to address than the checkers, Also resin sands easier than filament plastic.

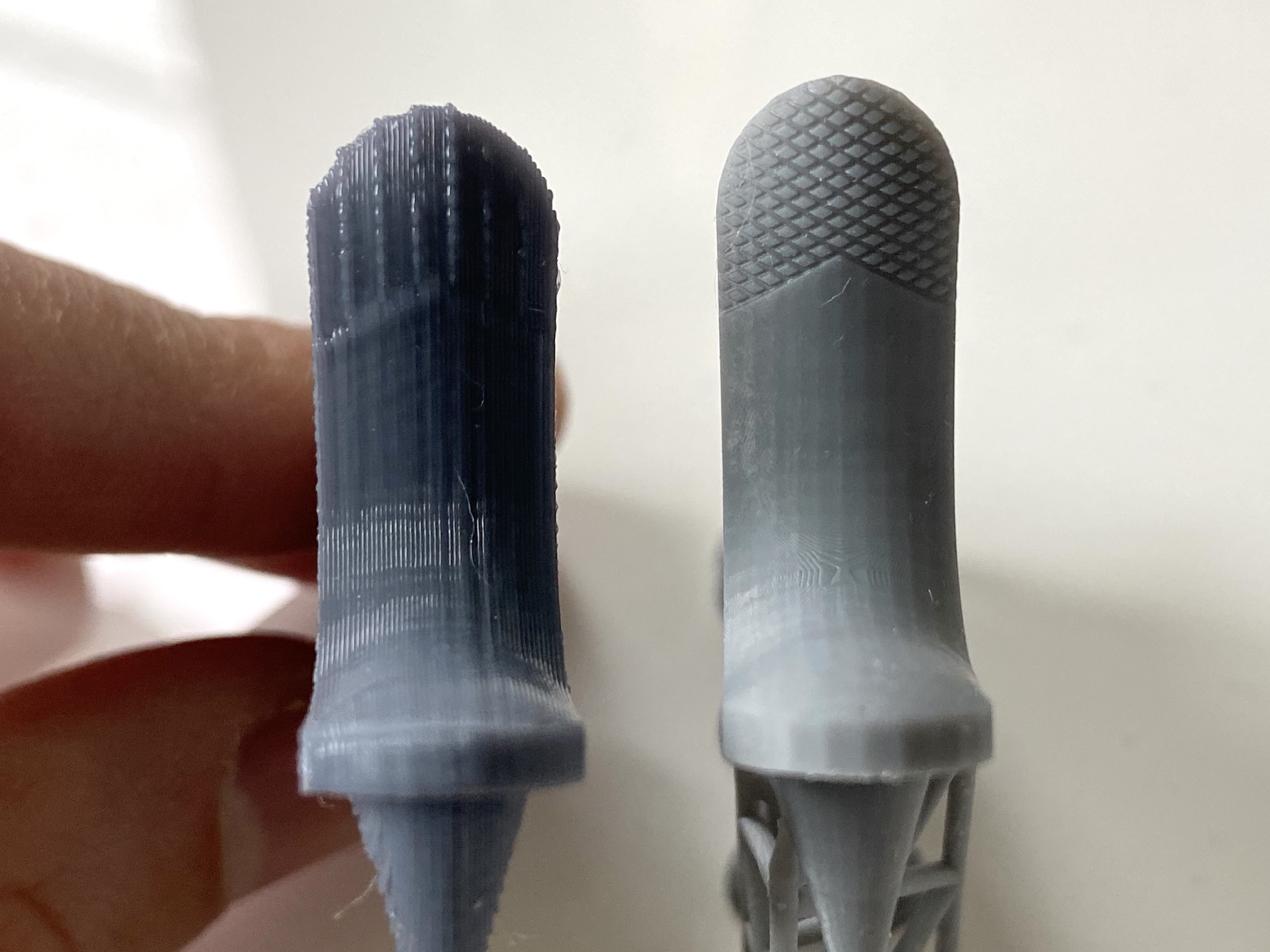

Here's a comparison of the new resin printed part with the original placeholder I made with my FDM (obviously I need to remove the supports):

And a closer look at that pattern:

If anyone is curious, the resin printer I chose was a Phrozen Sonic Mini 4K. It's a little printer, but high detail which is currently my need when making props/costumes. I think it's amazing to have both technologies as tools and I look forward to more projects where they work in together.

OK, back to work!

-Dana

You can definitely see that the checkered area came out clean and crisp. However, the resin printer also exposed the low-polygon nature of other areas of the model (particularly some curved surfaces). No worries, that's easily fixed with some sanding and it's a much simpler issue to address than the checkers, Also resin sands easier than filament plastic.

Here's a comparison of the new resin printed part with the original placeholder I made with my FDM (obviously I need to remove the supports):

And a closer look at that pattern:

If anyone is curious, the resin printer I chose was a Phrozen Sonic Mini 4K. It's a little printer, but high detail which is currently my need when making props/costumes. I think it's amazing to have both technologies as tools and I look forward to more projects where they work in together.

OK, back to work!

-Dana