Cruzer

Well-Known Hunter

Here's a tutorial from start to finish to assemble the gauntlets from kit form. I know I should have posted this a long time ago, but I finally found the time, so here it is. Thanks.

Here's what I would do in these steps:

----Notes----

I use a flat file to make the 45 degree(roughly) taper in pic #5.

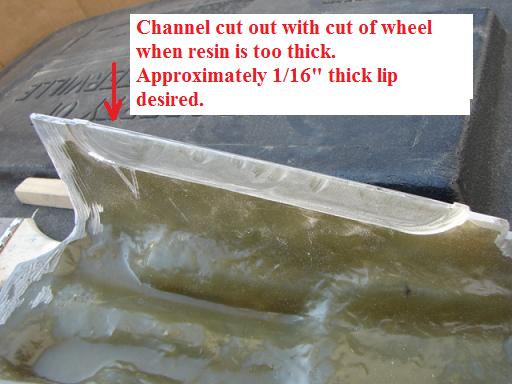

I cut a channel in the fiberglass with the cutoff wheel only when the resin is too thick for the desired 1/16"-3/32" lip. Most times, a channel is not necessary.

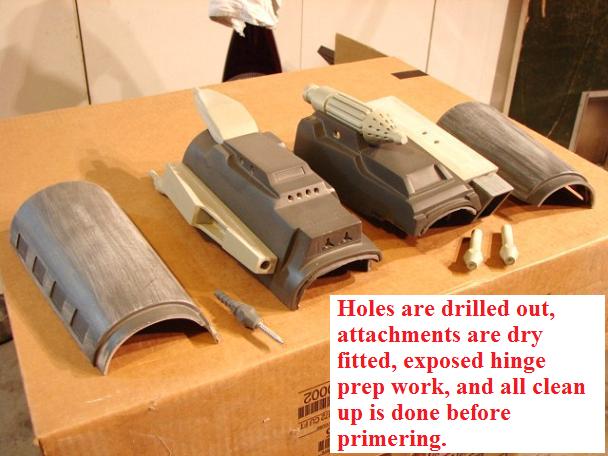

I prefer to finish trim/drill, primer, and finish sand the shells before I attach the hinge, however, it could be done before or after. The only reason I'm not drilling out the various holes is because they aren't my gauntlets, otherwise, I'd do that also before primering.

I use Super-T CA glue (green label) on the hinges themselves because it has a higher viscosity and I don't have to worry about the glue dripping. I try not to apply it close to the links, and I hold the hinge in place until it dries (45-60 seconds).

I then seal around the hinge edges/holes filling any gaps between the hinge and shells with the Special-T glue (yellow label). I'm careful not to let the glue run into the hinge links. Then I use the NCF Quick after I apply the Special-T to quickly cure and set everything. I don't recommend using the NCF Quick when initially setting the hinge with Super-T because it doesn't allow any time for repositioning because of its instant curing properties.

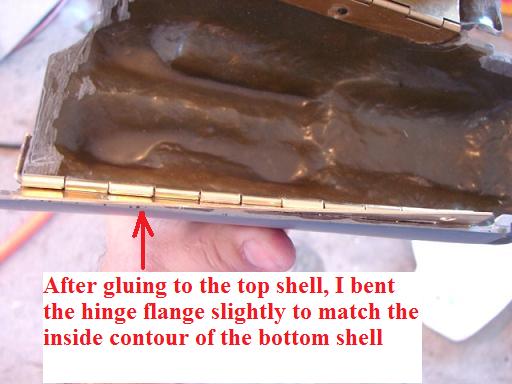

After the small exposed hinge is affixed, I applied heat mainly to the bottom shell to realign the edges. I then held them in the position I wanted and ran them under cool water in a sink to maintain the shape. If I had just let them air dry, they could start going back into their original unrealigned position. If after you have the hinge/pin side affixed there is still a lot of tension on the pin, I'd recommend heating up both sides significantly, placing the pin in and letting them cool with the pin installed. This should decrease the amount of tension that may be on the pin.

I'd recommend cutting off one link length from each of the hinge/pin closure lengths that came with the kits. I did that for the two pictured here and it made affixing the hinges a lot easier. It looks like I cut the hinges too long.

All the pics are of the left gauntlet because it is the more difficult in my opinion. The steps for the right gauntlet are exactly the same and is actually probably easier to assemble. I'd recommend starting with the right gauntlet since it's the easier of the two, and then tackle the left gauntlet.

Let me know if there are any questions.

Thanks,

Cruzer

Here's what I would do in these steps:

- Clean up all of the parts (flamethrower, flamethrower cap, flamethrower nozzles, whipcord, hose barb and flare nut, hose attachment, and missile) with an exacto knife, emory board, files, etc.

- Sand down the really tough spots (mostly on the flamethrower).

- Place a piece of sandpaper on a flat surface (i.e. the floor) and sand flat the back of the flamethrower cap.

- Glue the flamethrower cap onto the flamethrower. I use only CA glue, but any type of superglue or epoxy would work.

- Drill out the holes for the pushbuttons on the flamethrower with a 9/32" drill bit.

- Drill out the holes for the flamethrower nozzles on the flamethrower with a 3/8" drill bit.

- Predrill the hole for the hose barb attachment on the whipcord with a 9/64" drill bit.

- If you are using a Dark-Side aluminum whipcord dart, drill out the hole for the dart on whipcord with a 21/64" drill bit.

- Do any necessary spot filling with Bondo, Evercoat, spot putty, etc.

- Finish sand and all of the parts with 220 grit.

- Primer all of the parts with a spray-can primer. I prefer Krylon grey. If you let it dry overnight, you'll get better sanding results. 24 hours is even better.

- Finish sand with some 320 grit, then maybe 400 grit. Some people suggest 600 grit for the final sanding before Rn'B, but personally I've never used higher than 400. Wet-sanding also make a difference.

- Finish trim the front and back curvatures of all four shells with a Dremel and a 60 Grit Sanding Band (Dremel part #408).

- On the left top shell, drill out the hole for the chrome Halo_1 LED housing with a 5/16" drill bit.

- On the left top shell, drill and clean out the oblong hole for the slider switch with a Dremel and Multipurpose Cutting Bit (Dremel part #561).

- On the left top shell, drill out the holes for the missile with an 11/64" drill bit.

- On the right top shell, drill out the holes for the mini-toggle switches with a 3/16" or 13/64" drill bit.

- On the right top shell, drill out the holes for the 4 darts with a 5/32" drill bit.

- On the right top shell, drill out the holes for the 2 mini-darts with a 1/8" drill bit.

- One at a time, hold in place all of the attachment parts and drilling out the holes in the shells for the set screws with an 11/64" drill bit. You already did this for the missile in Step #4 above. There are 2 set screws for each part.

- Once those holes are drilled, you can hold the parts in place again and mark for the predrill holes.

- Predrill with a 3/32" drill bit.

- Follow the pictoral tutorial steps to cut out the recessed areas for the exposed hinges and to bevel the edges.

- Do any necessary spot filling with Bondo, Evercoat, spot putty, etc.

- Lightly finish sand all four shells with 320 grit. I say lightly because they're already pretty smooth. Be careful not to sand away the line detail in the front of the right top shell.

- Lightly primer and let dry overnight.

- Finish sand.

- Attach the exposed hinge following the pictoral tutorial.

- Attach the hidden hinge and pin closing system following the pictorial tutorial.

- Rn'B or paint.

----Notes----

I use a flat file to make the 45 degree(roughly) taper in pic #5.

I cut a channel in the fiberglass with the cutoff wheel only when the resin is too thick for the desired 1/16"-3/32" lip. Most times, a channel is not necessary.

I prefer to finish trim/drill, primer, and finish sand the shells before I attach the hinge, however, it could be done before or after. The only reason I'm not drilling out the various holes is because they aren't my gauntlets, otherwise, I'd do that also before primering.

I use Super-T CA glue (green label) on the hinges themselves because it has a higher viscosity and I don't have to worry about the glue dripping. I try not to apply it close to the links, and I hold the hinge in place until it dries (45-60 seconds).

I then seal around the hinge edges/holes filling any gaps between the hinge and shells with the Special-T glue (yellow label). I'm careful not to let the glue run into the hinge links. Then I use the NCF Quick after I apply the Special-T to quickly cure and set everything. I don't recommend using the NCF Quick when initially setting the hinge with Super-T because it doesn't allow any time for repositioning because of its instant curing properties.

After the small exposed hinge is affixed, I applied heat mainly to the bottom shell to realign the edges. I then held them in the position I wanted and ran them under cool water in a sink to maintain the shape. If I had just let them air dry, they could start going back into their original unrealigned position. If after you have the hinge/pin side affixed there is still a lot of tension on the pin, I'd recommend heating up both sides significantly, placing the pin in and letting them cool with the pin installed. This should decrease the amount of tension that may be on the pin.

I'd recommend cutting off one link length from each of the hinge/pin closure lengths that came with the kits. I did that for the two pictured here and it made affixing the hinges a lot easier. It looks like I cut the hinges too long.

All the pics are of the left gauntlet because it is the more difficult in my opinion. The steps for the right gauntlet are exactly the same and is actually probably easier to assemble. I'd recommend starting with the right gauntlet since it's the easier of the two, and then tackle the left gauntlet.

Let me know if there are any questions.

Thanks,

Cruzer

Last edited by a moderator: