Lazerjock

Active Hunter

This tutorial may be helpful if you have damaged or missing parts and access to a 3D printer.

Boochman & I are working together to replace missing parts for his jet pack. There was some interest in seeing the process.

I will be doing the printing and Boochman will do the final assembly and paint work. The 3D models were created by RafalFett and are available for download from his Shapeways page here:

www.shapeways.com

www.shapeways.com

I will be printing 3 models.

Jet Pack Rocket

Rocket Base

Thruster Nozzles

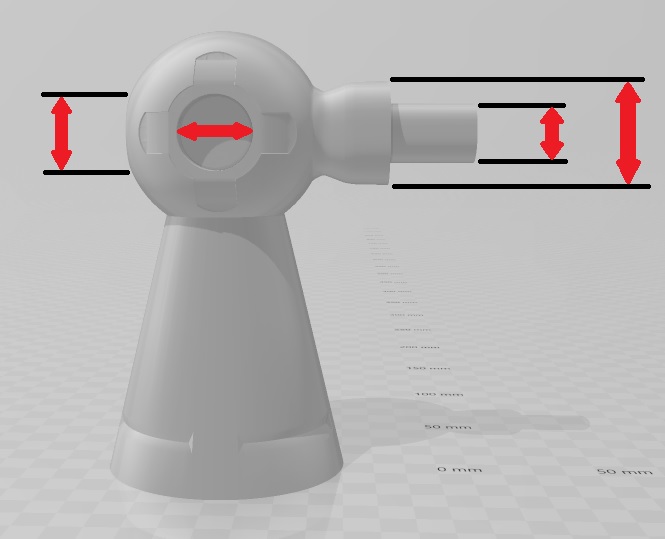

The models will need to be modified in order to mate properly with Boochman's jet pack and the metal parts he already has. So the first step is to get the dimensions. When doing this type of work digital calipers are required. A ruler or tape measure is not accurate enough. Inexpensive digital calipers can be picked up at Harbor Freight for around $20.

I will need to know these dimensions:

Boochman & I are working together to replace missing parts for his jet pack. There was some interest in seeing the process.

I will be doing the printing and Boochman will do the final assembly and paint work. The 3D models were created by RafalFett and are available for download from his Shapeways page here:

Rafal Works by rafalworks - Shapeways Shops

So far all my models are Star Wars - Boba Fett related, but I may add models from other universes too.

I will be printing 3 models.

Jet Pack Rocket

Rocket Base

Thruster Nozzles

The models will need to be modified in order to mate properly with Boochman's jet pack and the metal parts he already has. So the first step is to get the dimensions. When doing this type of work digital calipers are required. A ruler or tape measure is not accurate enough. Inexpensive digital calipers can be picked up at Harbor Freight for around $20.

I will need to know these dimensions: