JustBlais

New Hunter

Backstory: As a kid, I always wanted a suit of Stormtrooper (and Halo's SPARTAN) armor - learned pepakura, but never got past the "glue the paper together" stage. Kept up making occasional props here and there, but functionally abandoned the armor dream. Fast forward 15 years later, and a post appears on reddit of someone's graphite-painted Mandalorian helmet that they 3D printed...the fire is lit anew. Impulse bought a 3D printer (the Ender 3X) and decided it was time to start up a brand new hobby!

This thread is going to track my WIP build of this costume. I have some experience cosplaying before, but nothing with these degree of armor prop work (lots of Spider-Man and the like). My goal is to have this ready for the small expo we have in-town, and use it as a learning basis that will transition into making my own custom set!

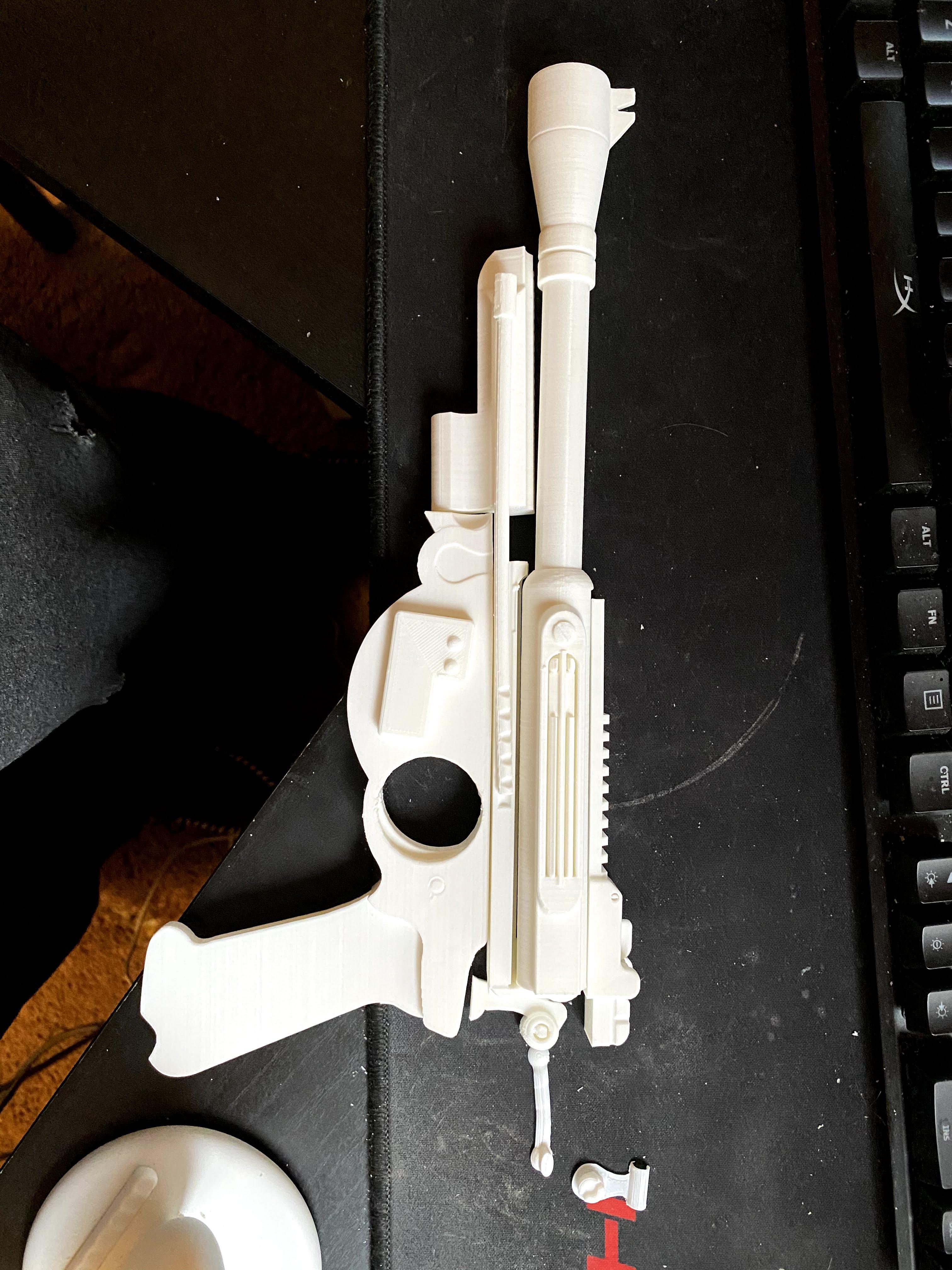

FIRST PRINT - Mandalorian Blaster Pistol

After that, it was time to move on to the next stage, the most exciting stage...the helmet!

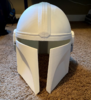

Mando Helmet

If anyone else has built using 3D prints before, would love to hear tips! Particularly if you live in cold climates - I'm Canadian and had to spend a LOT of time figuring out how people prime and fill in prints when it's cold outside (and you don't want to spray tons of primer-filler inside your place!).

This thread is going to track my WIP build of this costume. I have some experience cosplaying before, but nothing with these degree of armor prop work (lots of Spider-Man and the like). My goal is to have this ready for the small expo we have in-town, and use it as a learning basis that will transition into making my own custom set!

FIRST PRINT - Mandalorian Blaster Pistol

After some small cubes and other test prints, this pistol was the first thing I printed. I wanted to start with something small before I moved on to working on the actual armor and costume, so I could learn a little bit about printing. Ended up learning a lot! I think I'll ultimately come back to this pistol and re-do it down the line, after I have more experience, but for my first ever 3D print project (and indeed, first ever real painting project like this), I was happy with the results! Happy enough to keep going.)

Unfortunately, I didn't do a great job tracking the WIP status for this one, but here are what pictures I have.

Loosely laying out the printed pieces to get a sense of scale

Mostly glued and assembled!

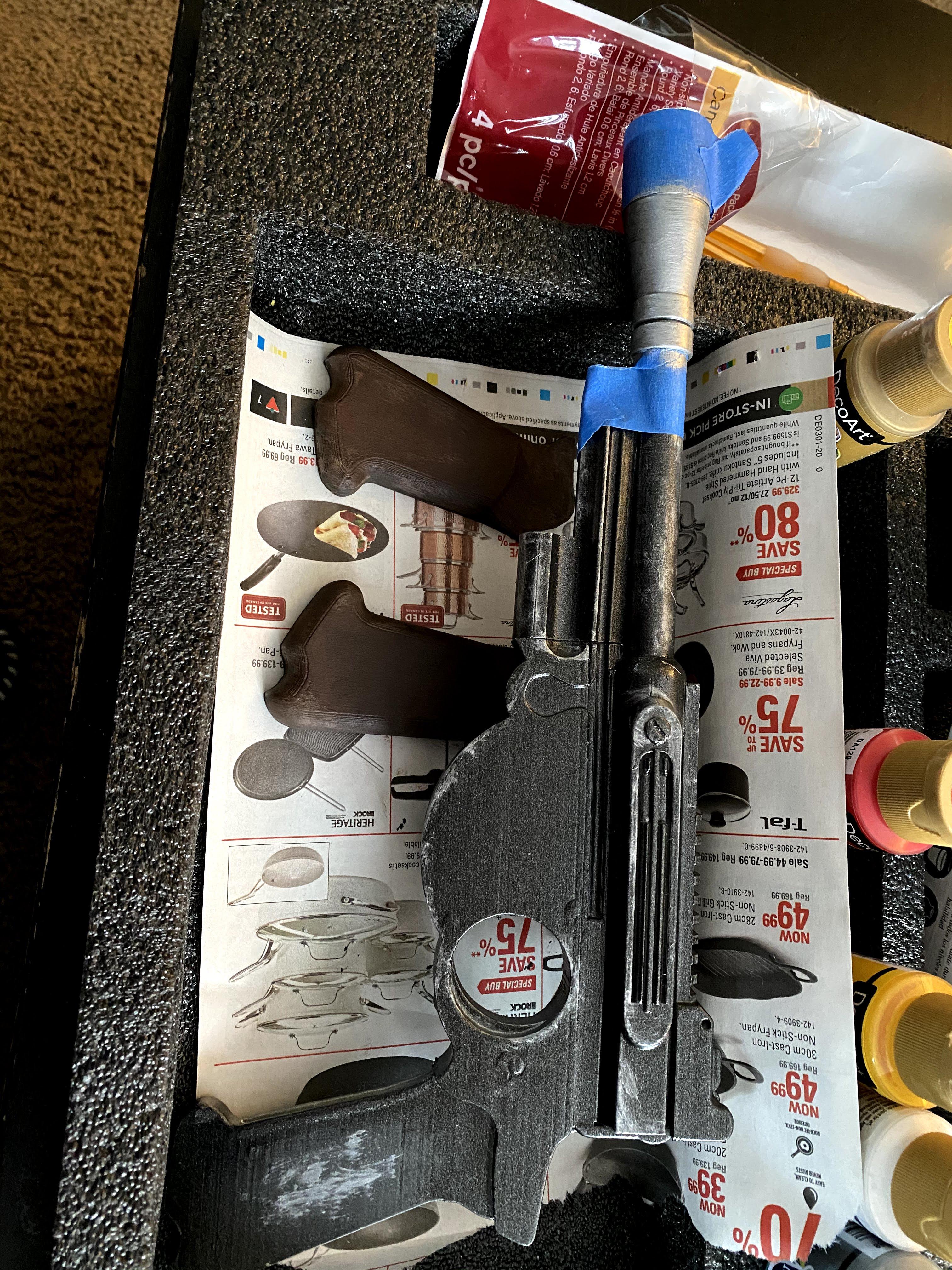

Skipping ahead a little bit - spray coats complete, taping off sections to paint silver! Some weathering already done (dry-brushed with silver acrylic.)

Complete! (See, told you I did a bad job tracking.)

Unfortunately, I didn't do a great job tracking the WIP status for this one, but here are what pictures I have.

Loosely laying out the printed pieces to get a sense of scale

Mostly glued and assembled!

Skipping ahead a little bit - spray coats complete, taping off sections to paint silver! Some weathering already done (dry-brushed with silver acrylic.)

Complete! (See, told you I did a bad job tracking.)

After that, it was time to move on to the next stage, the most exciting stage...the helmet!

Mando Helmet

Trying to do a better job of taking WIP pictures, but still not great!

Here's a link to the tweet I made of half the helmet taped up so I could get a sense of scale. Little did I know I taped the back incorrectly here, but that's ok! Whenever I'm coding or prototyping anything, I always try to get something "touchable" as fast as possible, as I find it dramatically increases my motivation to keep the project going. It sure worked here!

Assembled the "big" pieces - missing the vents and the ears. The lower front pieces were a real pain to glue, as there's very little actually connecting them to rest of the helmet - the sides are functionally free-standing until the ear components are added on.

Next up (after a brief vacation this weekend) - filler, a LOT of sanding, and prepping it for painting while the rest of the pieces print!

Here's a link to the tweet I made of half the helmet taped up so I could get a sense of scale. Little did I know I taped the back incorrectly here, but that's ok! Whenever I'm coding or prototyping anything, I always try to get something "touchable" as fast as possible, as I find it dramatically increases my motivation to keep the project going. It sure worked here!

Assembled the "big" pieces - missing the vents and the ears. The lower front pieces were a real pain to glue, as there's very little actually connecting them to rest of the helmet - the sides are functionally free-standing until the ear components are added on.

Next up (after a brief vacation this weekend) - filler, a LOT of sanding, and prepping it for painting while the rest of the pieces print!

If anyone else has built using 3D prints before, would love to hear tips! Particularly if you live in cold climates - I'm Canadian and had to spend a LOT of time figuring out how people prime and fill in prints when it's cold outside (and you don't want to spray tons of primer-filler inside your place!).

Attachments

Last edited: