So, lurked for a long time, but now with both of my boys (13 and 6) wanting to be mandelorians for Halloween, I've decided to get off my rear and get cracking on costumes. (Tried to get my daughter to go was Sabine, but she's not biting)

I've dabbled in auto repairs in my spare time on classic cars I've had over the decades, so fiberglass felt like a natural solution. Especially considering I've got a garage full of the stuff already.

Having to make 2 full suits by OCT, I gotta get to work. Not to mention I have to make one for me to, for... uh... testing puposes?

I started with WoF templates. Those things are amazing. I cut them out and used a gluestuck to marry them to cardboard. I went the cheapskate route for this first build and used the cardboard from the back of giant desk calendars I had lying around work. Wasn't as sturdy as If prefer. I'll definitely use 2mm grey board next go round. Also, cutting, then glueing, then cutting again was overkill. Not to mention it causes problems later and had to be (mostly) removed.

Overall, the assembly wasn't too bad. I just used hot glue to hold things together. I'll be reinforcing the entire helmet with fiberglass matting before bondo, so glue bits won't be an issue.

Additionally, I've just hot glued this sucker down to a wood plan from an old project. Thus should offer stability while I layer the glass. Once I get to the bottom and have some rigid glass on, I'll pull that off to glass in the bottom ridge.

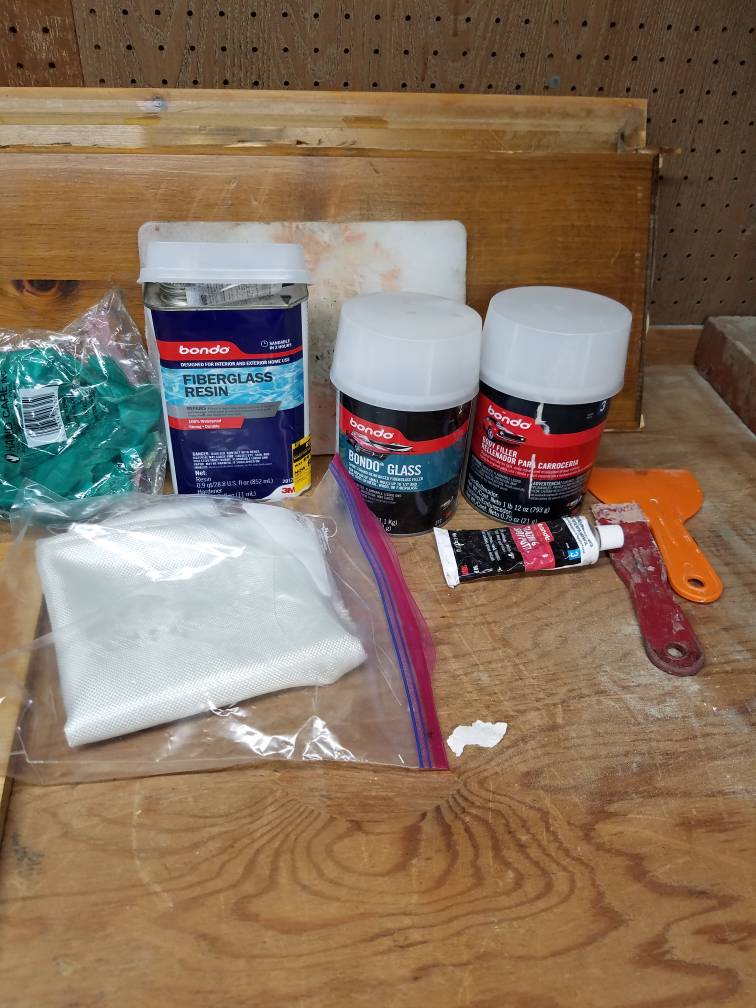

Anyhow, here's where were at now. Assembled cardboard helmet. Second photo is the gear I'm using for phase 2. Matting, resin, a few bondo variations, and some spot putty. I'll probably tackle that over the weekend and post some updates.

Sent from my SM-G930T

I've dabbled in auto repairs in my spare time on classic cars I've had over the decades, so fiberglass felt like a natural solution. Especially considering I've got a garage full of the stuff already.

Having to make 2 full suits by OCT, I gotta get to work. Not to mention I have to make one for me to, for... uh... testing puposes?

I started with WoF templates. Those things are amazing. I cut them out and used a gluestuck to marry them to cardboard. I went the cheapskate route for this first build and used the cardboard from the back of giant desk calendars I had lying around work. Wasn't as sturdy as If prefer. I'll definitely use 2mm grey board next go round. Also, cutting, then glueing, then cutting again was overkill. Not to mention it causes problems later and had to be (mostly) removed.

Overall, the assembly wasn't too bad. I just used hot glue to hold things together. I'll be reinforcing the entire helmet with fiberglass matting before bondo, so glue bits won't be an issue.

Additionally, I've just hot glued this sucker down to a wood plan from an old project. Thus should offer stability while I layer the glass. Once I get to the bottom and have some rigid glass on, I'll pull that off to glass in the bottom ridge.

Anyhow, here's where were at now. Assembled cardboard helmet. Second photo is the gear I'm using for phase 2. Matting, resin, a few bondo variations, and some spot putty. I'll probably tackle that over the weekend and post some updates.

Sent from my SM-G930T