Necronaut

Hunter

Hey guys.

Among my many Fett projects I currently have on the go, I really didn't need to add another project to the list. BUT I REALLY WANTED TO!!

On Monday or Tuesday, I'll be taking delivery of a bunch of Clone armour and helmet parts that will eventually turn into Clone Commander Bly from ROTS, my second SW costume. He has a pair of pistol sidearms, but I thought I'd up the bad @$$ quotient a little with this Clone DC-15A rifle:

From Wookiepedia

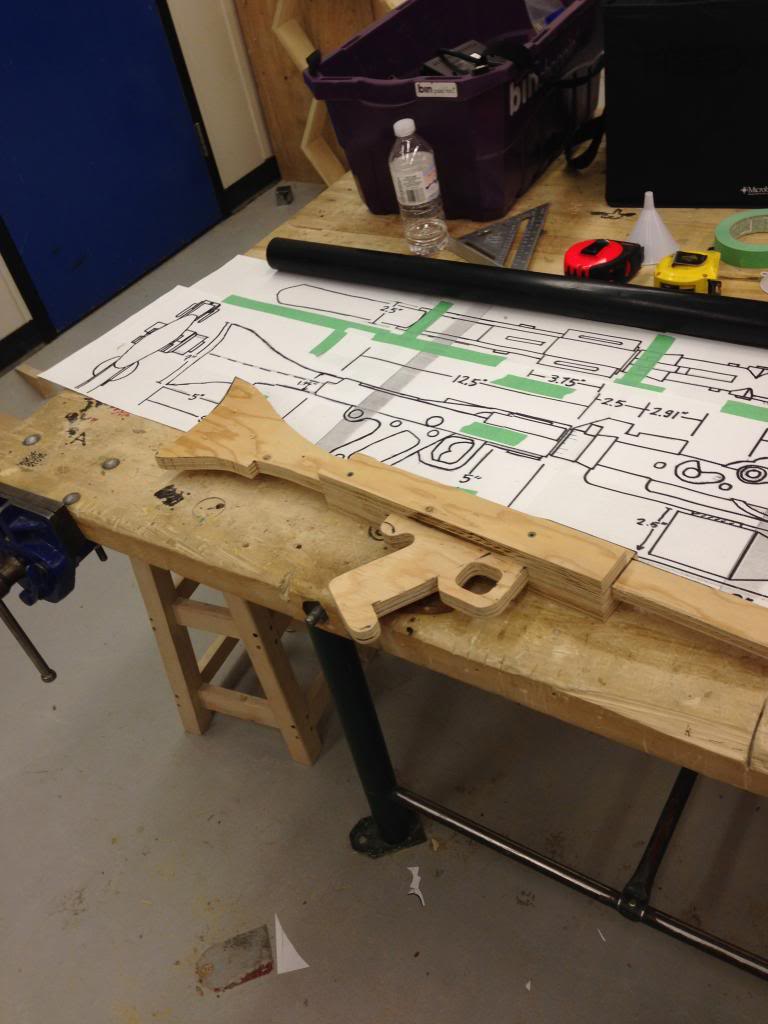

I started with what I think is a template originally made by wizardofflight for the old SW blaster builder boards. It had to be enlarged almost 600%. After putzing around at the school photocopier for a few hours (did I mention we're on spring break right now?), I had my templates. Time to start cutting some wood...

I've seen a lot of DC-15A builds that look like they could use a little Viagra, if you know what I mean. Because the rifle is so long, they tend to bend and sag. I didn't want that to happen to mine! I used a 3/4" plywood for the core of the build. I used the template to trace the back half of the rifle onto the plywood, then cut out as many of the straight and long cuts a I could on the table saw to ensure parallel, straight cuts. Everything else was cut out on the bandsaw or with Forstner bits for any tight curves.

I cut a 1 1/2" shaft sticking out of the front to mount my PVC pipe to. I am hoping that this will eliminate any tendency for the rifle to droop when held up.

I used the same sheet of 3/4" plywood to cut out the sides for the breech. They were screwed on.

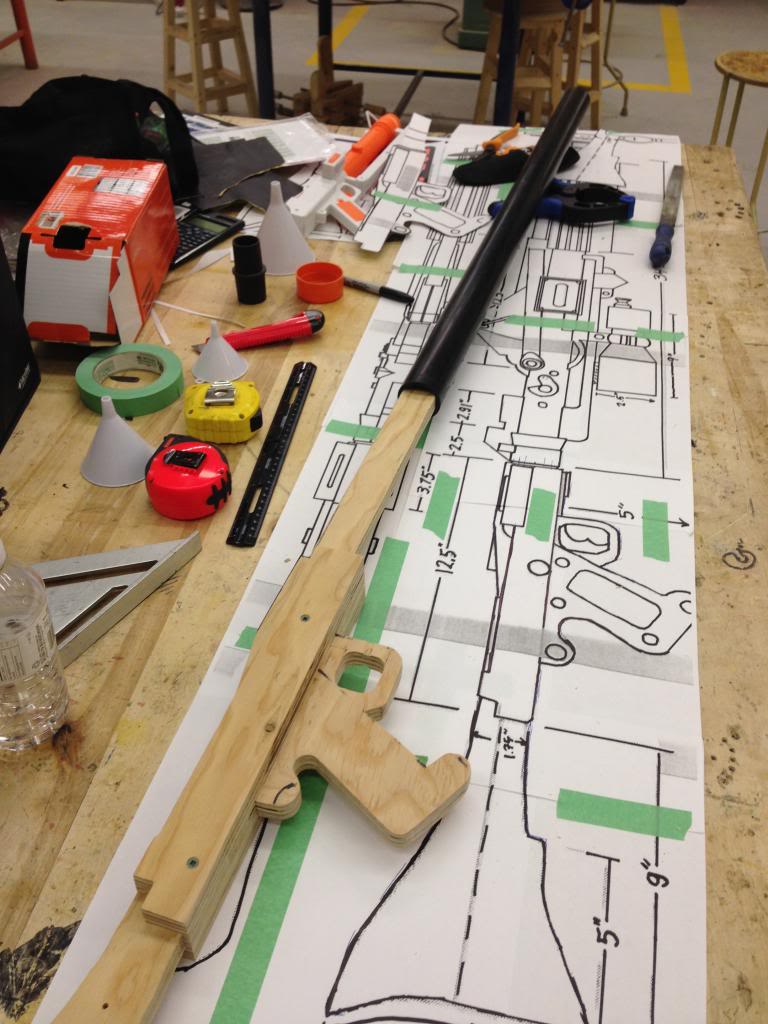

Here's a pic of the PVC sleeve for the front of the rifle. I used a rasp to round off the edges of the front part so the pipe would slide onto it. It's a pretty tight fit, which is exactly what I wanted. A couple screws and some epoxy ought to keep it from moving.

Pretty much every sander in the shop is out of commission. That's kinda bad for this because the rifle stock is really contoured. To overcome this, I used some pine (a soft, easily shaped wood) to block out the sides of the rifle stock. I contoured the shape using a hand rasp, then sanded it with a drum sander on the drill press and a mouse/detail sander.

It's screwed and glued onto the rifle. I'll let it set overnight, then I'll start blocking out the detail parts all over the rifle.

Cheers!

Among my many Fett projects I currently have on the go, I really didn't need to add another project to the list. BUT I REALLY WANTED TO!!

On Monday or Tuesday, I'll be taking delivery of a bunch of Clone armour and helmet parts that will eventually turn into Clone Commander Bly from ROTS, my second SW costume. He has a pair of pistol sidearms, but I thought I'd up the bad @$$ quotient a little with this Clone DC-15A rifle:

From Wookiepedia

I started with what I think is a template originally made by wizardofflight for the old SW blaster builder boards. It had to be enlarged almost 600%. After putzing around at the school photocopier for a few hours (did I mention we're on spring break right now?), I had my templates. Time to start cutting some wood...

I've seen a lot of DC-15A builds that look like they could use a little Viagra, if you know what I mean. Because the rifle is so long, they tend to bend and sag. I didn't want that to happen to mine! I used a 3/4" plywood for the core of the build. I used the template to trace the back half of the rifle onto the plywood, then cut out as many of the straight and long cuts a I could on the table saw to ensure parallel, straight cuts. Everything else was cut out on the bandsaw or with Forstner bits for any tight curves.

I cut a 1 1/2" shaft sticking out of the front to mount my PVC pipe to. I am hoping that this will eliminate any tendency for the rifle to droop when held up.

I used the same sheet of 3/4" plywood to cut out the sides for the breech. They were screwed on.

Here's a pic of the PVC sleeve for the front of the rifle. I used a rasp to round off the edges of the front part so the pipe would slide onto it. It's a pretty tight fit, which is exactly what I wanted. A couple screws and some epoxy ought to keep it from moving.

Pretty much every sander in the shop is out of commission. That's kinda bad for this because the rifle stock is really contoured. To overcome this, I used some pine (a soft, easily shaped wood) to block out the sides of the rifle stock. I contoured the shape using a hand rasp, then sanded it with a drum sander on the drill press and a mouse/detail sander.

It's screwed and glued onto the rifle. I'll let it set overnight, then I'll start blocking out the detail parts all over the rifle.

Cheers!