You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boushh Boushh Helmet/Costume Build by alvo

- Thread starter alvomedia

- Start date

alvomedia

Hunter

Amazing build thread right here. Excellent work.

Thanks! I am trying to be as thorough as possible. I've spent about a year researching the costume, and relied heavily on threads from other builders. So I hope this thread will be useful for others as well!

alvomedia

Hunter

The spats for the boots have been a work in progress. My first attempt was a fail, in my eyes anyway. So I re-tooled the pattern to get it right. I'm more interested in getting it right than making it passable. Plus, it's like I always say - it's my signature style to always have to do things twice.

I picked up these boots on amazon for $15 and I'm seriously impressed that they aren't total garbage. Yes, they are made from totally synthetic material, but you only see the toe of the boot, so why spend more than you need to? The color is perfect, and I think they are a great match. I got half a size larger than I usually do so I can put a good supportive insole in them to make them nice and comfortable.

It took me 2 tries to get the spats right. I made pattern, did all the stitching, and in the end realised that they just weren't right. The spats on the original costume come down and cover much more of the boot. So I took the pattern and reworked it. They just didn't look right. You can see them here:

So after I fixed the pattern things went really well. I used the same material used for the tunic. For the batting I used this really neat fusible quilters batting that I could iron onto the material. It really worked well and made the spats more stiff so they won't sag.

I first cut out the material then fused one piece onto the quilt batting. I trimmed around the edges to remove the excess batting then sewed the two pieces together, good sides together Once they were sewn together I flipped them right side out and ironed the other side to fuse it to the batting.

After this point I measured out the vertical lines about 1.25" apart, sewing every second line as a double line. I added some velcro on the back to keep it closed and a strap that will go under the boot and keep it in place as well.

I'm not finished with the spats yet. I haven't gotten the boot disks yet, and will have to sew up the piece that goes across the front and round the sides. I've the buckles that will go on the backs. But I think that version 2.0 of the spats came out nicely.

I picked up these boots on amazon for $15 and I'm seriously impressed that they aren't total garbage. Yes, they are made from totally synthetic material, but you only see the toe of the boot, so why spend more than you need to? The color is perfect, and I think they are a great match. I got half a size larger than I usually do so I can put a good supportive insole in them to make them nice and comfortable.

It took me 2 tries to get the spats right. I made pattern, did all the stitching, and in the end realised that they just weren't right. The spats on the original costume come down and cover much more of the boot. So I took the pattern and reworked it. They just didn't look right. You can see them here:

So after I fixed the pattern things went really well. I used the same material used for the tunic. For the batting I used this really neat fusible quilters batting that I could iron onto the material. It really worked well and made the spats more stiff so they won't sag.

I first cut out the material then fused one piece onto the quilt batting. I trimmed around the edges to remove the excess batting then sewed the two pieces together, good sides together Once they were sewn together I flipped them right side out and ironed the other side to fuse it to the batting.

After this point I measured out the vertical lines about 1.25" apart, sewing every second line as a double line. I added some velcro on the back to keep it closed and a strap that will go under the boot and keep it in place as well.

I'm not finished with the spats yet. I haven't gotten the boot disks yet, and will have to sew up the piece that goes across the front and round the sides. I've the buckles that will go on the backs. But I think that version 2.0 of the spats came out nicely.

alvomedia

Hunter

I wanted to take a break from all the sewing, so I thought I'd start weathering some of the clothing pieces. I started with the cape, using shoe polish. The results were underwhelming, and I wasn't very happy with the product. I was trying for a more gradual/blend for the cape. It just turned out blotchy. You can see the results here:

So I soaked the cape in some hot water with a bit of laundry detergent to tone down/get rid of the shoe polish weathering. Then I went and got my bottle of india ink and mixed up a bath to try and dye the cape that way. The results where great, I think. It created a nice dirty gradient.

I figured this was a good time to do the tunic too, so that got some weathering too. I soaked the tunic in the india ink bath then pulled it out to let it drip dry. I added a bit more grime to the tunic by putting a drop or two of india ink on my hands and wiping it directly onto the tunic while it was still wet. As the tunic dried, some of the ink bled out with the water dripping off, so I may have to go back and add just a touch more in a few strategic places.

I also had a pretty great idea for the pants for the gathered areas around the knees. But I'll have to put that in another post. Pretty good day today.

So I soaked the cape in some hot water with a bit of laundry detergent to tone down/get rid of the shoe polish weathering. Then I went and got my bottle of india ink and mixed up a bath to try and dye the cape that way. The results where great, I think. It created a nice dirty gradient.

I figured this was a good time to do the tunic too, so that got some weathering too. I soaked the tunic in the india ink bath then pulled it out to let it drip dry. I added a bit more grime to the tunic by putting a drop or two of india ink on my hands and wiping it directly onto the tunic while it was still wet. As the tunic dried, some of the ink bled out with the water dripping off, so I may have to go back and add just a touch more in a few strategic places.

I also had a pretty great idea for the pants for the gathered areas around the knees. But I'll have to put that in another post. Pretty good day today.

DeathProof

Active Hunter

Great work! Those pants were a huge pain. Nice job on the weathering - the drip method really makes a nice gradient!

Badgerdash

Jr Hunter

This is an amazing progress thread. Thanks for sharing.

DeathProof

Active Hunter

Thank god we're finally on page 2. That load time near the end was getting crazy

alvomedia

Hunter

This is an amazing progress thread. Thanks for sharing.

Thanks! Happy to share!

Thank god we're finally on page 2. That load time near the end was getting crazy

Yea, I know right! Sorry for the picture heavy thread. lol.

DeathProof

Active Hunter

Hahah! No worries

alvomedia

Hunter

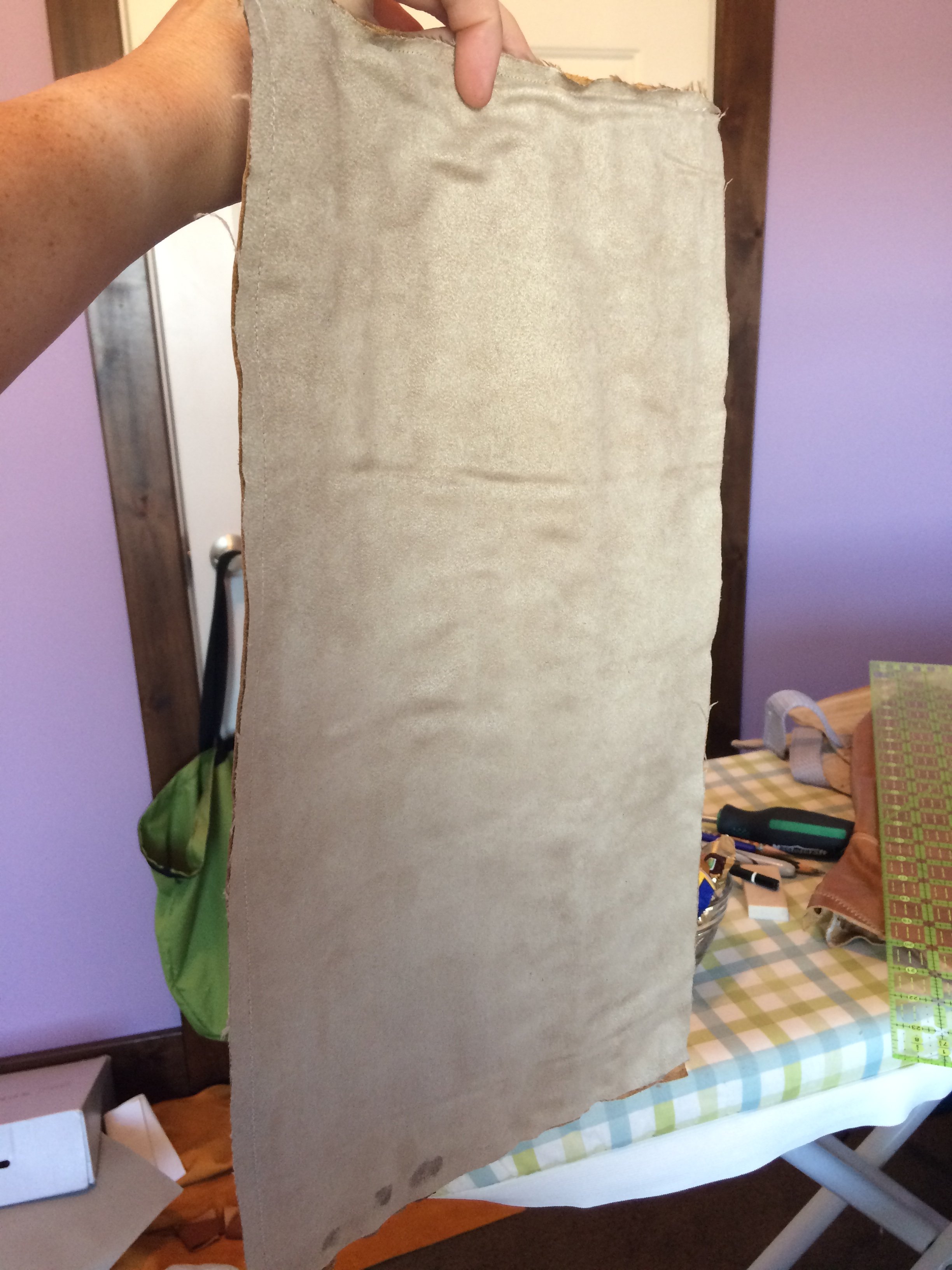

Alright, pants update. It sort of dawned on me finally one night how to get the wrinkled/folding effect on the pants at the knees. First, I didn't want to sew pleats into the knees for the effect. Secondly, I really liked a wrinkled look, achieved by soaking the leather then letting it dry in a bunched up bundle all tied together. My only problem with this method was I was skeptical as to how long the wrinkles would stay crisp and defined. So then I had a sort of light bulb moment. What if I took the dried out, wrinkled piece of leather and somehow glued it to another piece of material to keep the wrinkles from disappearing after repeated wearing? I figured it was worth a shot.

I ended up using some krylon spray adhesive, recommended for use with material etc. and is supposed to stay flexible. I cut out a piece of material (same as the tunic) that was the right size for where I was sewing them onto the pants. I sewed two sides of the leather to the material (one short, one long side). Then I simply sprayed the adhesive onto the leather and the material and pressed them together, keeping the wrinkles defined. Then I sewed the other two sides, just for good measure.

And then I had a beautifully defined wrinkled knee patch.

I went to try and sew the piece onto my pants, but in some parts the needle has to go through 4 layers of leather and my sewing machine just wasn't having it. So I stalled there. Luckily I have a friend with a legitimate leather sewing machine that will do the job easily. The pants were one of the items I just wasn't sure how to approach, so I'm glad it is working out WAY better than I anticipated!

I ended up using some krylon spray adhesive, recommended for use with material etc. and is supposed to stay flexible. I cut out a piece of material (same as the tunic) that was the right size for where I was sewing them onto the pants. I sewed two sides of the leather to the material (one short, one long side). Then I simply sprayed the adhesive onto the leather and the material and pressed them together, keeping the wrinkles defined. Then I sewed the other two sides, just for good measure.

And then I had a beautifully defined wrinkled knee patch.

I went to try and sew the piece onto my pants, but in some parts the needle has to go through 4 layers of leather and my sewing machine just wasn't having it. So I stalled there. Luckily I have a friend with a legitimate leather sewing machine that will do the job easily. The pants were one of the items I just wasn't sure how to approach, so I'm glad it is working out WAY better than I anticipated!

DeathProof

Active Hunter

Nice!

We ended up gluing the wrinkles in an accordion fashion. Loads of fun... love the colour of those pants too!

love the colour of those pants too!

We ended up gluing the wrinkles in an accordion fashion. Loads of fun...

alvomedia

Hunter

Just a quick update on the progress of the Boushh build. The spikes/studs for the sleeves/gloves came in the mail yesterday, and I've been excited to get these on so this piece of the costume can go into the "finished" box. This is a pretty straight forward process. I did reinforce the back of the material with some leather, just so the spikes wouldn't tear through. The leather was attached with some leather glue/contact cement. Again, this adhesive should stay flexible with a strong bond.

After the leather was put on, it was just a matter of marking out where the spikes would go then cutting small hole and screwing them on. Very easy. Now I just need to find the right pair of gloves.

After the leather was put on, it was just a matter of marking out where the spikes would go then cutting small hole and screwing them on. Very easy. Now I just need to find the right pair of gloves.

Marycontrary

New Hunter

Great build. Am so enjoying seeing your progress.

Sent from my iPad

Sent from my iPad

alvomedia

Hunter

Great build. Am so enjoying seeing your progress.

Sent from my iPad

Thanks so much!

alvomedia

Hunter

Another quick post. Tunic = DONE

All I had to do here was add some velcro to keep things secure, and sew some slits/holes for my armor attachments. I've got some straps that attach to the armor that keep the armor from slipping back, and the straps are meant to be hidden beneath the tunic. Hence, the slits/holes just below the shoulders.

As far as other soft parts, I think I am about 75-85% done. The only really big item I have left for soft parts is the pants, and I'm just waiting on a good time to use my friends leather sewing machine.

Also, I need a belt. Especially the belt buckle. I've seen the 3D printed ones, but I'm not sure I want to pay out that kind of money for such a small part.

And I'm still searching for the large cup thingy that is attached to the bandolier.

I realise that I've been quite thorough on this build/posts, almost to the point of overkill. But I'm a pretty visual person, so when I'm trying to find out how to do something I love seeing pictures. So this is the kind of build thread that helps me along on builds, and hopefully it will be useful to others!

All I had to do here was add some velcro to keep things secure, and sew some slits/holes for my armor attachments. I've got some straps that attach to the armor that keep the armor from slipping back, and the straps are meant to be hidden beneath the tunic. Hence, the slits/holes just below the shoulders.

As far as other soft parts, I think I am about 75-85% done. The only really big item I have left for soft parts is the pants, and I'm just waiting on a good time to use my friends leather sewing machine.

Also, I need a belt. Especially the belt buckle. I've seen the 3D printed ones, but I'm not sure I want to pay out that kind of money for such a small part.

And I'm still searching for the large cup thingy that is attached to the bandolier.

I realise that I've been quite thorough on this build/posts, almost to the point of overkill. But I'm a pretty visual person, so when I'm trying to find out how to do something I love seeing pictures. So this is the kind of build thread that helps me along on builds, and hopefully it will be useful to others!

alvomedia

Hunter

alvomedia

Hunter

Working on the helmet now, so this will be home for the next 7 to 10 days.

The kit is one of Todd's (Sandman on TDH). This is a really great kit, clean casts. This is I think the 6th paint up I've done of Todd's Boushh helmets, and they are always great to work with. The kit comes with all the necessary pieces for greeblies and lenses. I've been working on it all afternoon but at this point there isn't anything to show. I always spend the first few hours sanding and prepping the helmet. There are some seams that usually need some TLC, but honestly there isn't much to do on this beautiful bucket. I spend a lot of time sanding because then the paint/primer just takes to the helmet nicer. So I start with about a 220 grit and work my way up to a finer paper to keep things nice and smooth. I always wear coveralls at this stage, because that resin dust just gets everywhere.

I'll probably cut out the lens holes next, which is also a messy process. Lots of prep before I can get to paint. Goggles and dust mask are a good idea for that. I'll probably have a lot of posts for the next 2 weeks. Be prepared.

The kit is one of Todd's (Sandman on TDH). This is a really great kit, clean casts. This is I think the 6th paint up I've done of Todd's Boushh helmets, and they are always great to work with. The kit comes with all the necessary pieces for greeblies and lenses. I've been working on it all afternoon but at this point there isn't anything to show. I always spend the first few hours sanding and prepping the helmet. There are some seams that usually need some TLC, but honestly there isn't much to do on this beautiful bucket. I spend a lot of time sanding because then the paint/primer just takes to the helmet nicer. So I start with about a 220 grit and work my way up to a finer paper to keep things nice and smooth. I always wear coveralls at this stage, because that resin dust just gets everywhere.

I'll probably cut out the lens holes next, which is also a messy process. Lots of prep before I can get to paint. Goggles and dust mask are a good idea for that. I'll probably have a lot of posts for the next 2 weeks. Be prepared.

alvomedia

Hunter

Cut the lens holes this morning. This is usually my least favorite part of the build. It is a little bit tedious, as you have to really take care when you are cutting with the dremel and sanding. If there is any advice I can give here, it is to take your time and do it right.

I always start with the top lens hole. I usually mark it in first, about 1/8"-3/16" in from the edge. I use a cutting wheel to get the bulk of it out first, leaving room to sand it down to a more precise and clean edge. The actual lens needs to be trimmed down too, usually. Also, the inside needs sanding. You will need to create a lip/edge for the lens to sit flush against. This is where some patience will really come in handy. Keep putting the lens in to make sure your fit is good. It is tricky, given where you have to get your tools in, but if you do it right it will look great in the end.

The bottom lens hole is a bit easier. Again, the bulk is cut out with dremel. For this I use an 80 grit sand paper on the inside to prepare it for the lens. If you can run your sand paper along both edges where the lens sits (like shown in the picture) I have found that this will get you a near perfect fit. Previously I had used a dremel tool with a sanding drum to try and get a good fit. It worked okay with that method, but it was far more tedious. After you get a good fit with the 80 grit, clean it up with something finer like 220 or 320.

I also cut out a slot on the snout, where I will be installing a fan on the inside. I will have to drill some holes in the tusk piece that covers the snout to create an opportunity for some air-flow.

Not finished with the messy bits yet. Still need to draw and cut in the battle scars (which is my favorite part!) and trim the "hood" that goes on the top of the helmet.

But I think I'll do the ear greeblies next. I'll post again later today with more progress.

I always start with the top lens hole. I usually mark it in first, about 1/8"-3/16" in from the edge. I use a cutting wheel to get the bulk of it out first, leaving room to sand it down to a more precise and clean edge. The actual lens needs to be trimmed down too, usually. Also, the inside needs sanding. You will need to create a lip/edge for the lens to sit flush against. This is where some patience will really come in handy. Keep putting the lens in to make sure your fit is good. It is tricky, given where you have to get your tools in, but if you do it right it will look great in the end.

The bottom lens hole is a bit easier. Again, the bulk is cut out with dremel. For this I use an 80 grit sand paper on the inside to prepare it for the lens. If you can run your sand paper along both edges where the lens sits (like shown in the picture) I have found that this will get you a near perfect fit. Previously I had used a dremel tool with a sanding drum to try and get a good fit. It worked okay with that method, but it was far more tedious. After you get a good fit with the 80 grit, clean it up with something finer like 220 or 320.

I also cut out a slot on the snout, where I will be installing a fan on the inside. I will have to drill some holes in the tusk piece that covers the snout to create an opportunity for some air-flow.

Not finished with the messy bits yet. Still need to draw and cut in the battle scars (which is my favorite part!) and trim the "hood" that goes on the top of the helmet.

But I think I'll do the ear greeblies next. I'll post again later today with more progress.

alvomedia

Hunter

I like to get this part of the helmet build finished in one day, just because of the mess it makes.

For the next part I assembled the ear greeblies with some CA glue. You need to drill two holes in the helmet for the "L" shaped cylinder pieces to go into. It helps to dry fit everything before you commit with any glue. The other holes that were drilled are for air flow. As air is sucked into the helmet VIA the fan located in the snout of the helmet, the air will also need somewhere to vent to create good air flow. Putting some vents hidden under the ear pieces will help with air flow, and maybe even help with being able to hear a bit better. We'll see.

I like to add some putty to the ear pieces as well. To the "L" shaped piece going into the helmet, helps give it a fused/welded look. And on the rest of it just for strength, really.

Now for the messiest part of all. Trimming and fitting the hood. I've got a template for the hood, so it makes it relatively easy to trim to roughly the right shape. Again, a dremel tool, some patience and constant dry fitting should get you a good fit in the end.

I'll add the battle scars later this evening, and finish everything off by sanding with a very fine grit to get as smooth a finish as possible.

For the next part I assembled the ear greeblies with some CA glue. You need to drill two holes in the helmet for the "L" shaped cylinder pieces to go into. It helps to dry fit everything before you commit with any glue. The other holes that were drilled are for air flow. As air is sucked into the helmet VIA the fan located in the snout of the helmet, the air will also need somewhere to vent to create good air flow. Putting some vents hidden under the ear pieces will help with air flow, and maybe even help with being able to hear a bit better. We'll see.

I like to add some putty to the ear pieces as well. To the "L" shaped piece going into the helmet, helps give it a fused/welded look. And on the rest of it just for strength, really.

Now for the messiest part of all. Trimming and fitting the hood. I've got a template for the hood, so it makes it relatively easy to trim to roughly the right shape. Again, a dremel tool, some patience and constant dry fitting should get you a good fit in the end.

I'll add the battle scars later this evening, and finish everything off by sanding with a very fine grit to get as smooth a finish as possible.

Similar threads

- Replies

- 0

- Views

- 265

- Replies

- 9

- Views

- 864

- Replies

- 1

- Views

- 957

- Replies

- 7

- Views

- 5,976