Gator Fett

Well-Known Hunter

When I painted my custom aluminum collar and backplate, I also painted my chest armor. I did not take or attempt to share any progress pics, because the masking paint technique has been discussed in various other threads. What I would like to share is my armor attachment method and my final product.

The four chest pieces (right, left, ab & diamond) and the two shoulder bells were made by Durasteel back in the summer of 2002. They are made from 1/8" thick aluminum plate, and as I have stated in other posts, are great pieces of armor. Personally, I like aluminum armor over vac'ed plastic or sintra. It just feels more real.

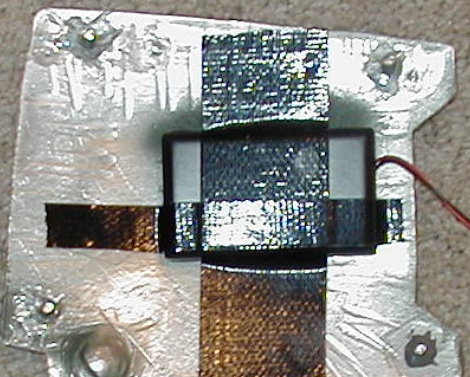

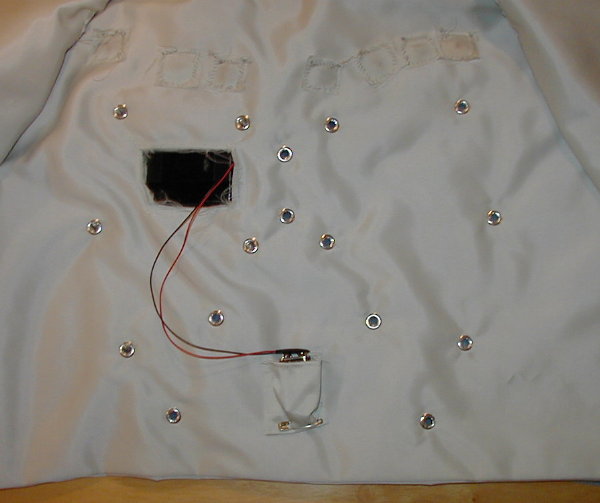

I decided to attach my armor plates with screws and nuts rather than velcro or the magnets I used on my backplate and collar. First I cut the heads off of #8-32 x 5/8" screws. I then drilled small indentations or pits in the back side of the armor in the corners. CAUTION: do not drill through the armor. Using JB Weld, I epoxied the screws into the drill indents. Once the epoxy had dried, I used the screws to locate the grommet holes in the vest. Then I installed the grommets at the screw locations.

Prior to attaching the screws, I used my plates as a template for sintra "washers" which will hold the plates close to the vest material. I drilled holes in the sintra washers at the screw locations, and secured everything together with small metal washers and nuts.

How did I do?

The four chest pieces (right, left, ab & diamond) and the two shoulder bells were made by Durasteel back in the summer of 2002. They are made from 1/8" thick aluminum plate, and as I have stated in other posts, are great pieces of armor. Personally, I like aluminum armor over vac'ed plastic or sintra. It just feels more real.

I decided to attach my armor plates with screws and nuts rather than velcro or the magnets I used on my backplate and collar. First I cut the heads off of #8-32 x 5/8" screws. I then drilled small indentations or pits in the back side of the armor in the corners. CAUTION: do not drill through the armor. Using JB Weld, I epoxied the screws into the drill indents. Once the epoxy had dried, I used the screws to locate the grommet holes in the vest. Then I installed the grommets at the screw locations.

Prior to attaching the screws, I used my plates as a template for sintra "washers" which will hold the plates close to the vest material. I drilled holes in the sintra washers at the screw locations, and secured everything together with small metal washers and nuts.

How did I do?