ToEleven

Active Hunter

For the past several weeks I've been working on a new helmet which I plan to mold and cast. I'm using Rafalfett's V2 templates as a base for the helmet with a few tweaks along the way. I'm not intending for this to be a wearable helmet...inspired somewhat by Terminal Fettler's build from the scratch build sticky.

I hope that maybe some of what I'm doing would be helpful for others who are foolhardy enough to sink their time into scratch building.

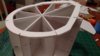

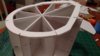

I used rafalworks from 3dwarehouse.com helmet to get my dome base started. This is not actually how the file represents it. I had to separate the dome and slice it in another program.

The base is foam core poster board. You have to trim height from the supports if you want to use this material since it's a bit thicker than the templates allow for. I also use 2mm Sintra/Celtec for the covering.

I hope that maybe some of what I'm doing would be helpful for others who are foolhardy enough to sink their time into scratch building.

I used rafalworks from 3dwarehouse.com helmet to get my dome base started. This is not actually how the file represents it. I had to separate the dome and slice it in another program.

The base is foam core poster board. You have to trim height from the supports if you want to use this material since it's a bit thicker than the templates allow for. I also use 2mm Sintra/Celtec for the covering.