I wondered about that too. If I compare the angle of the bottom edge in profile it appears to be the same, so the lower back mandible being lower doesn't make sense. I think it must have to do with the camera angles/distance etc. I know for a fact that my camera angle isn't exact to the other one. You can tell when you look at the way the T part of the visor curves back around on the same side of the helmet. Just doesn't quite match up. Oh, well. I tried. But thanks for pointing that out. It also may be that my lid is slightly different in shape on top of the angle being different. I'm prepared to accept that as a possibility. I'm also prepared to leave it as it is LOL.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GB's bucket progress - WOF plans ROCK

- Thread starter Gypsyboy

- Start date

wizardofflight

Well-Known Hunter

Beautiful job!! That is one great looking helmet!

Now it is time to paint it! Have you decided what version you are going to go with?

Can't wait to see it complete.

Alan

P.S. I was surprised at the size myself, But I crossed checked against a number of sources to make sure that I got it the same size as the movie version. For myself I need to print it out at least 107% which make more along the size of the mystry helmet. (big head)

Now it is time to paint it! Have you decided what version you are going to go with?

Can't wait to see it complete.

Alan

P.S. I was surprised at the size myself, But I crossed checked against a number of sources to make sure that I got it the same size as the movie version. For myself I need to print it out at least 107% which make more along the size of the mystry helmet. (big head)

Last edited by a moderator:

SD68

Active Hunter

GB, the work you have done is incredible. I can't believe how close the comparison pics you posted are. The dome shape, the angle of the cheeks, the proportions-everything! You definitely have a winner. A winning paint job will take it to the next level. Good luck and keep us posted.

Thanks guys !!

I'll be going for the Empire paintjob. I just love that cat scratch LOL. I also just find the whole Empire version to be cooler looking.

It occured to me, however, that I haven't made the ear pieces yet. I just started them last night. I expect it'll take me some time to get out and collect up all the different colours I need in the right kinds of paint.

I think I'll make myself a colour chart that shows the actual colours rather than just the paint name and number. That way I can compare the colours in the store even if it's a completely different brand with a name/number of its own.

I'll be going for the Empire paintjob. I just love that cat scratch LOL. I also just find the whole Empire version to be cooler looking.

It occured to me, however, that I haven't made the ear pieces yet. I just started them last night. I expect it'll take me some time to get out and collect up all the different colours I need in the right kinds of paint.

I think I'll make myself a colour chart that shows the actual colours rather than just the paint name and number. That way I can compare the colours in the store even if it's a completely different brand with a name/number of its own.

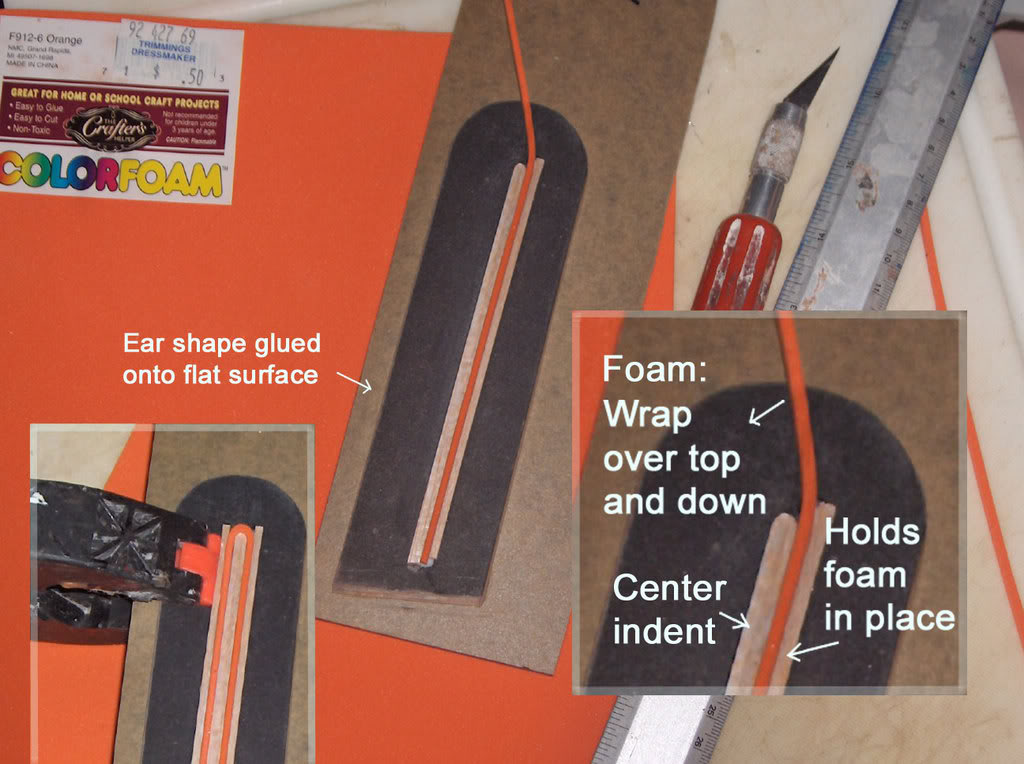

I'm starting with the right ear. It easy. Practice good. Me get smart from this.

The orange foam (which take tight contours much better than paper or card) defines the center slot along the length. It rests against the balsa form in the middle, and is held in place against it with glue and little balsa sticks. The next step will be to make the card stock cap for the sloped edge all around.

The orange foam (which take tight contours much better than paper or card) defines the center slot along the length. It rests against the balsa form in the middle, and is held in place against it with glue and little balsa sticks. The next step will be to make the card stock cap for the sloped edge all around.

GCNgamer128

Sr Hunter

Very cool! Turned out really nice

The dent does look a little high. I think it's *partly* due to the slightly different angle, but I expect it could very well actually be just a tad too high. In that particular photo comparison you can tell, but to just hold the thing and look at it you would probably never know. Heck, I didn't realize it till I looked at it in the pic above LOL.

As for how much... I can't really say at the moment. I would have to consider how much work and material, as well as to what degree of finished I would have to make it. I'm thinking a raw casting would be under a hundred (I would lay up at least 3 layers of f'glass if I was to sell one - I put two on mine, and although it's fairly strong the lower face / mandible area is a little too easy to bend for my liking). Anyway, a finished one would be a lot more work of course. It's hard to say just yet how much, as I haven't finished my own yet.

As for how much... I can't really say at the moment. I would have to consider how much work and material, as well as to what degree of finished I would have to make it. I'm thinking a raw casting would be under a hundred (I would lay up at least 3 layers of f'glass if I was to sell one - I put two on mine, and although it's fairly strong the lower face / mandible area is a little too easy to bend for my liking). Anyway, a finished one would be a lot more work of course. It's hard to say just yet how much, as I haven't finished my own yet.

Ghostsoldier

Active Hunter

I like the way the ear build is going....good idea...

Rob

Rob

Thanks again Rob.

I forgot to mention that I plan to cast my earpieces in resin, which is why I glued the thing down onto a surface to work it and keep it flat. Just in case it doesn't make sense to people why I would do that.

I started putting the sloped cap on last night, but I had to improvise because I lost the sheet of paper with the template for the cap piece. (and my printer is konked out) Dunno what happened to it. Fortunately, I have a wierd natural sense of how to shape things to make them fit, so I essentially guessed at it. Anywho... more to come on this one.

I forgot to mention that I plan to cast my earpieces in resin, which is why I glued the thing down onto a surface to work it and keep it flat. Just in case it doesn't make sense to people why I would do that.

I started putting the sloped cap on last night, but I had to improvise because I lost the sheet of paper with the template for the cap piece. (and my printer is konked out) Dunno what happened to it. Fortunately, I have a wierd natural sense of how to shape things to make them fit, so I essentially guessed at it. Anywho... more to come on this one.

I've been trying to make a visual reference for the colours found on the ESB lid. This is a work in progress, and I expect to have to make some changes, as well as some additions because I don't have the right ear colours yet. I don't really recommend using this as a guide for your lid if you are going for as accurate as possible, because as we all know different printers print colours differently. BUT, I want to make a visual guide for myself so I can go out with the colours in front of me and find what I need from whatever brand of paint happens to be at the paint (hobby) shop. Here's how it looks so far.

I think the left ear colour should actually be the same as the dome - but I could be wrong.

I think the left ear colour should actually be the same as the dome - but I could be wrong.

GrottyFurball

Active Hunter

Very nice work! Just wanted to point out that at the bottom of the channel on the left ear cap is actually rounded and not straight.

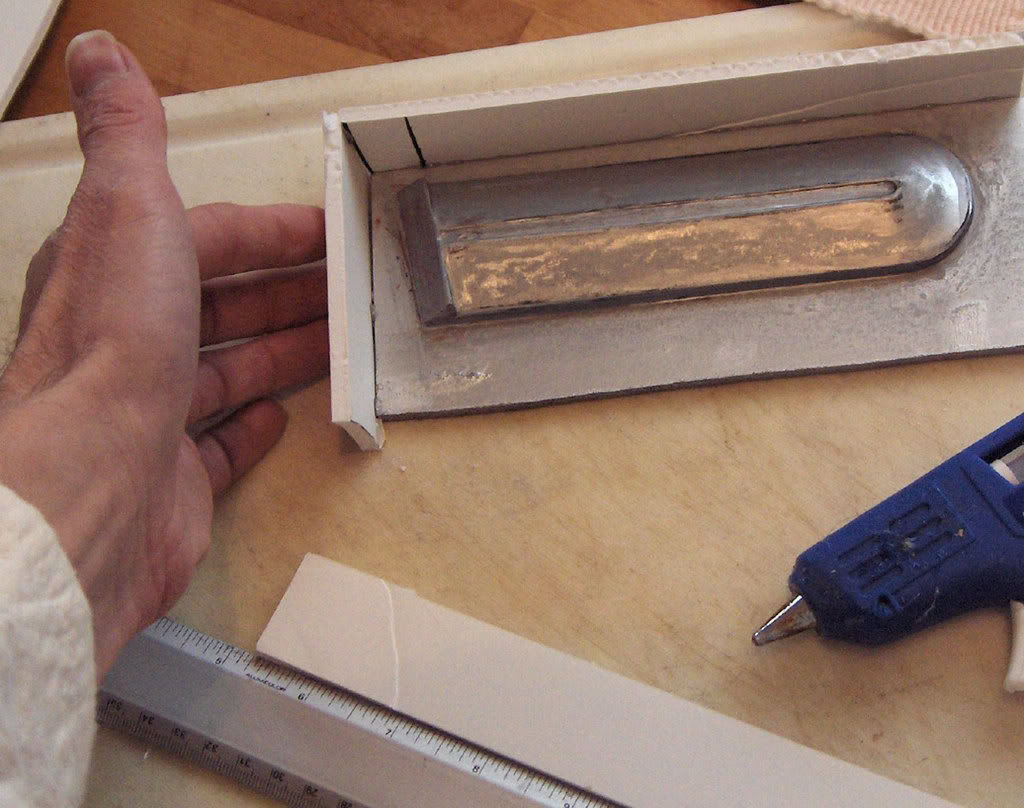

I did more work on the surface of the left earpiece, and built a box around it to make a mold.

You can see above that I fixed a minor detail that was pointed out to me on TDH... the bottom of the center channel is rounded.

OK, so the box is just foamcore hotglued in place.

Then I just mixed my silicone and poured it into the box. I did this slowly, making sure the bubbles were out.

Now I wait.

You can see above that I fixed a minor detail that was pointed out to me on TDH... the bottom of the center channel is rounded.

OK, so the box is just foamcore hotglued in place.

Then I just mixed my silicone and poured it into the box. I did this slowly, making sure the bubbles were out.

Now I wait.

GCNgamer128

Sr Hunter

Very cool

sithlord23

Well-Known Hunter

Awesome thread. Great work bud!

The silicone sat overnight in the box, to be sure it's completely cured, and this morning I released it.

Although I wish I had poured just a little more silicone to make the bottom of the mold a tad thicker it turned out really well. With a slightly thinner bottom than I would like it means I will have to be sure the mold is sitting on a very flat surface before pouring. I would do that anyway, so no big deal.

It's too cold now to do any resin casting (as I have to work outside - no indoor workspace for fumes like that), so it may be a while before I get the ears cast. The alternative is that I get ahold of some kind of resin, or something, that doesn't have noxious fumes.

Although I wish I had poured just a little more silicone to make the bottom of the mold a tad thicker it turned out really well. With a slightly thinner bottom than I would like it means I will have to be sure the mold is sitting on a very flat surface before pouring. I would do that anyway, so no big deal.

It's too cold now to do any resin casting (as I have to work outside - no indoor workspace for fumes like that), so it may be a while before I get the ears cast. The alternative is that I get ahold of some kind of resin, or something, that doesn't have noxious fumes.

Similar threads

- Replies

- 4

- Views

- 866

- Replies

- 4

- Views

- 1,060