Slave1Pirate117

Hunter

Hello everyone! Today I began working on some of the pieces I cut yesterday.

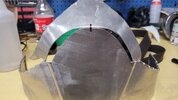

At first I wanted to test the stencil I made and printed on the helmet. I am doing the helmet face different this time so I will make the cut outs AFTER the face is shaped. I cut along the lines with a razor knife to score the aluminum for me to follow after the paper is removed.

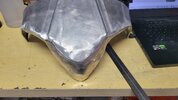

After that, I moved on to some armor parts. The first I did was the kidney plate. I started with the largest bends first.

I then began bending the small tabs

Then it was time to shape it to my waste

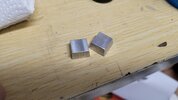

I moved on to the cod piece. The first thing I wanted to do was put the offsets in before bending the hems that way the hems didn't interfere with the bead roller.

A bead roller is a manual or motorized machine the puts beads or offsets in sheet metal. Changing the rollers on the end makes different shapes. In this case I wanted an offset on either side of the central cod piece as it should be. Doing this allows less material while providing the same shape.

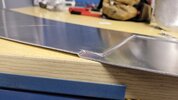

After that I moved on the bending the hems tabs. Btw, the point of the hems is to make the metal look heftier than it is and to provide softer edges that won't cut cloth or skin.

I then started shaping the central cod area to be more bowed out and shaped to my waste.

So I was able to complete these two pieces. I will need to weld all the seams so they look as if they are solid and of course the dents that make it Boba's armor.

Thanks for following along!

At first I wanted to test the stencil I made and printed on the helmet. I am doing the helmet face different this time so I will make the cut outs AFTER the face is shaped. I cut along the lines with a razor knife to score the aluminum for me to follow after the paper is removed.

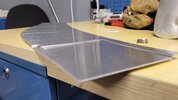

After that, I moved on to some armor parts. The first I did was the kidney plate. I started with the largest bends first.

I then began bending the small tabs

Then it was time to shape it to my waste

I moved on to the cod piece. The first thing I wanted to do was put the offsets in before bending the hems that way the hems didn't interfere with the bead roller.

A bead roller is a manual or motorized machine the puts beads or offsets in sheet metal. Changing the rollers on the end makes different shapes. In this case I wanted an offset on either side of the central cod piece as it should be. Doing this allows less material while providing the same shape.

After that I moved on the bending the hems tabs. Btw, the point of the hems is to make the metal look heftier than it is and to provide softer edges that won't cut cloth or skin.

I then started shaping the central cod area to be more bowed out and shaped to my waste.

So I was able to complete these two pieces. I will need to weld all the seams so they look as if they are solid and of course the dents that make it Boba's armor.

Thanks for following along!