You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

C6 Clonetrooper tutorial and build from head to toe!

- Thread starter DW Design

- Start date

clonecollector

Well-Known Hunter

I never knew about "fiber glass tape". Can I find it at Walmart? I have a OSCS kit and when I did my forearms I used the excess cutoff behind the back of the seam. I found there were spots where the excess strip had bubbles and didn't adhere. This tape method may just work out better for me when I do my legs and thighs. Thanks!

I've never heard of "fiber glass tape" either but I have used fiberglass cloth to repair cracked areas. I would lay down a thin layer of 2 part epoxy, lay the fiber cloth on it, press it down, and then smear more epoxy over it. Where can we find fiber glass tape? sounds like that way would be easier than what I have done.

clonecollector

Well-Known Hunter

I've layed fiber glass matting down too. This indeed would make it very easy.

clonecollector

Well-Known Hunter

Thanks for the tip Darren. I'll do a search!

faroshuffle

New Hunter

Darren,

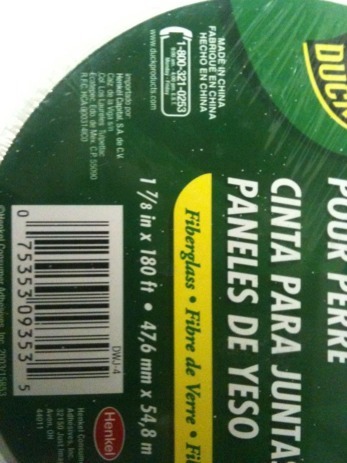

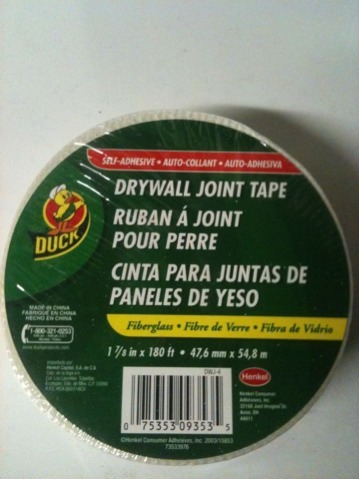

Is this the same type of Fiberglass Tape?

I purchased this in Walmart instead of Tap Plastics.

Is this the same type of Fiberglass Tape?

I purchased this in Walmart instead of Tap Plastics.

darth z

Active Hunter

Darren, the fiberglass tape you use is not sticky at both side, right... So the 2-part epoxy can be easily applied... Faroshuffle's tape is just like most of the scotch tapes with one side sticky and that is most i found locally as well... Which one is better, the sticky-at-one-side one and the one you use... besides, how wide is the tape gonna be...is the 25mm wide one ok or more wider ones are needed...

cheers,

frank

cheers,

frank

faroshuffle

New Hunter

I plan on testing it out this coming weekend...hang in there guys.

MentalMando

New Hunter

Wow you really are putting your blood sweat and tears into these but effort is really paying off.

Keep up the great work.

Keep up the great work.

DW Design

Active Hunter

I am not sure why they call it fiberglass tape. It's not sticky at all. I think it might be used to repair boats? It's just what C6 came up with years ago and it always worked for me.Darren, the fiberglass tape you use is not sticky at both side, right... So the 2-part epoxy can be easily applied... Faroshuffle's tape is just like most of the scotch tapes with one side sticky and that is most i found locally as well... Which one is better, the sticky-at-one-side one and the one you use... besides, how wide is the tape gonna be...is the 25mm wide one ok or more wider ones are needed...

cheers,

frank

DW Design

Active Hunter

Day 3

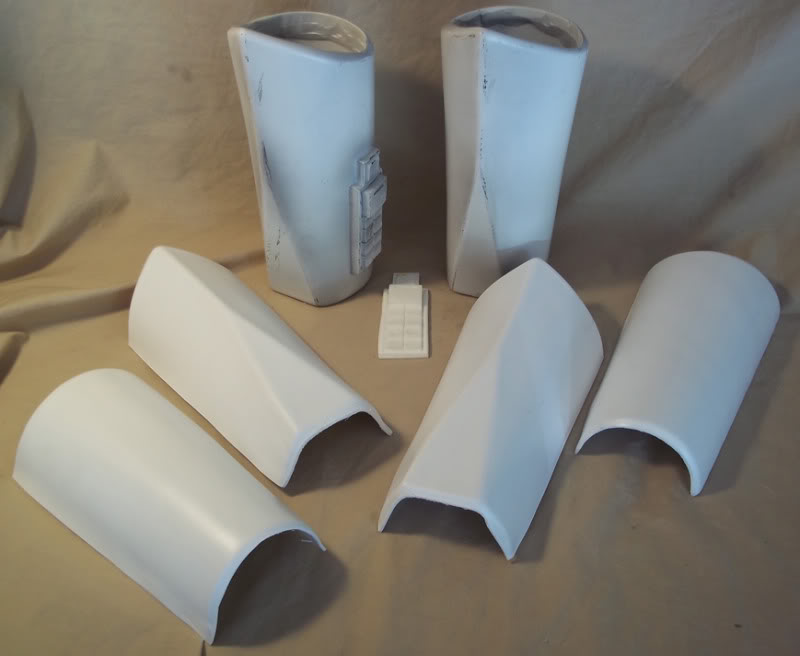

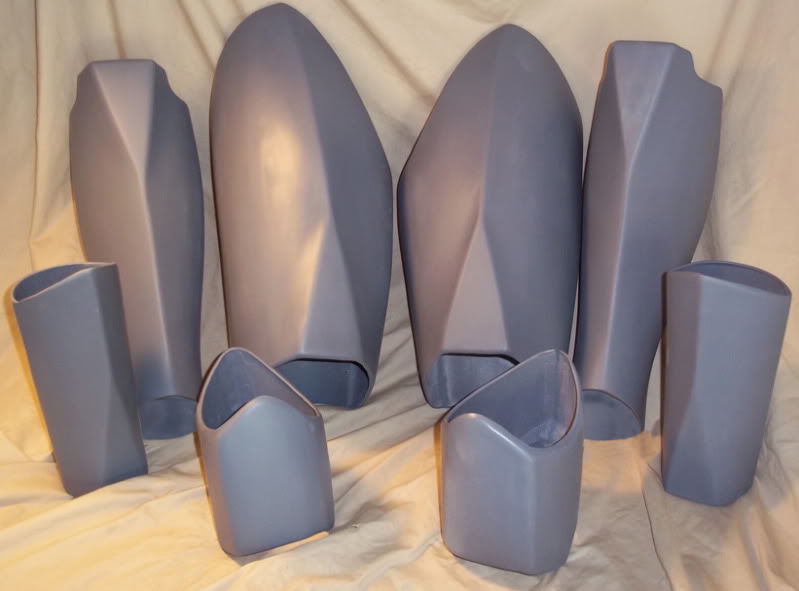

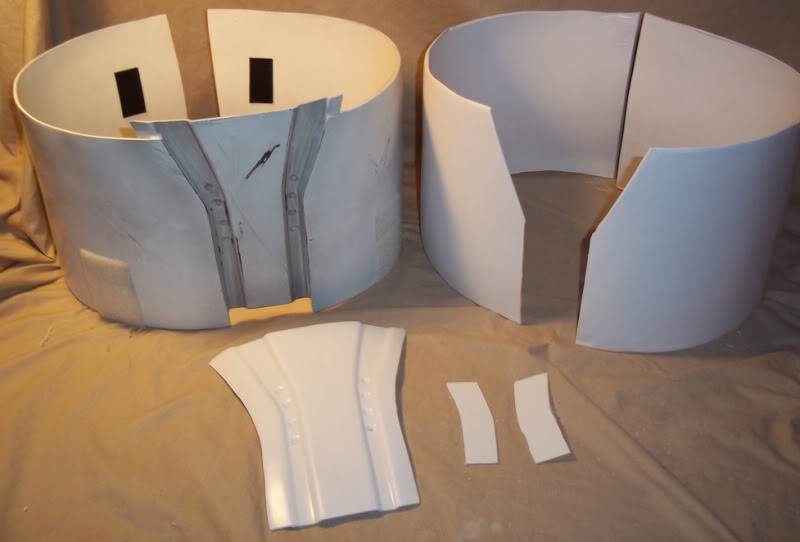

Moving onto the remaining items that need to go seamless we will begin to

work with the thighs, forearms and biceps. Same as the calves we will try to

cut or sand a straight line on one of the two halves. Once one of the two seams

are looking good, tape it up and start on the second side. Use a pencil if need

to help with this process. The photo’s below show a set of unassembled pieces and

a set of finished versions.

Here is a closer look at the biceps. The back of the biceps are always a little thought

to get to line up. Don't worry, this can be fixed when we add the epoxy and fiberglass tape.

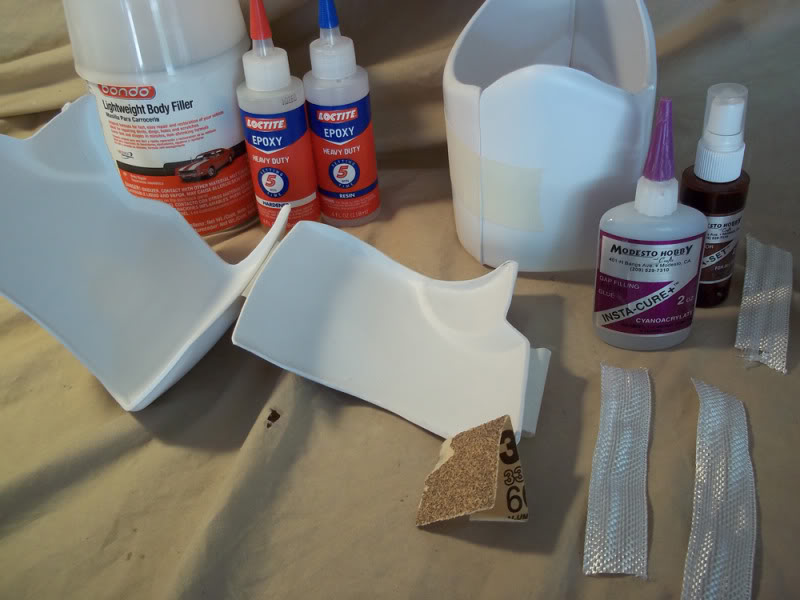

OK, now we have all the seams cut it time to start adding the insta-cure (super glue), epoxy and fiberglass tape.

Use masking or painters tape to tape all the part together. Add super glue to the inside seam.

Use the insta-set spray to help set the insta-cure.

After dried, add the epoxy and fiberglass tape to the inside seam. Then add another coating of epoxy to

the top of the fiberglass tape. Remove the masking or painters tape from the outside and fill in any gaps with epoxy.

Wait about a day and then sand the outside seams. Once seam is sanded add Bondo to outside seam and try to

cleanup and low spots or remaining blemishes. Sand and cleanup as needed. I use a Mouse Sander for this step.

Moving onto the remaining items that need to go seamless we will begin to

work with the thighs, forearms and biceps. Same as the calves we will try to

cut or sand a straight line on one of the two halves. Once one of the two seams

are looking good, tape it up and start on the second side. Use a pencil if need

to help with this process. The photo’s below show a set of unassembled pieces and

a set of finished versions.

Here is a closer look at the biceps. The back of the biceps are always a little thought

to get to line up. Don't worry, this can be fixed when we add the epoxy and fiberglass tape.

OK, now we have all the seams cut it time to start adding the insta-cure (super glue), epoxy and fiberglass tape.

Use masking or painters tape to tape all the part together. Add super glue to the inside seam.

Use the insta-set spray to help set the insta-cure.

After dried, add the epoxy and fiberglass tape to the inside seam. Then add another coating of epoxy to

the top of the fiberglass tape. Remove the masking or painters tape from the outside and fill in any gaps with epoxy.

Wait about a day and then sand the outside seams. Once seam is sanded add Bondo to outside seam and try to

cleanup and low spots or remaining blemishes. Sand and cleanup as needed. I use a Mouse Sander for this step.

DW Design

Active Hunter

Day 4

Sand and prime the seams as needed. You may need to add more Bondo. Another great item to use

is Bondo Glazing and Spot Putty. It good for the smaller holes. The nice thing is ready to use right out of the tube.

No mixing needed. This can be purchased at Wal Mart or any automotive store.

Once your seams are getting close I like to use Dupli-Color Filler Primer. This is a spray primer that I

have only begin to use recently. One of my R2 builder buddy’s suggested it.

It is a kind off expensive but it works great.

It can be found at automotive stores and costs around $8.00 per can.

Once again, keep sanding and priming until you are happy with the seams.

Once finished you should have a pile of parts that look like this.

Sand and prime the seams as needed. You may need to add more Bondo. Another great item to use

is Bondo Glazing and Spot Putty. It good for the smaller holes. The nice thing is ready to use right out of the tube.

No mixing needed. This can be purchased at Wal Mart or any automotive store.

Once your seams are getting close I like to use Dupli-Color Filler Primer. This is a spray primer that I

have only begin to use recently. One of my R2 builder buddy’s suggested it.

It is a kind off expensive but it works great.

It can be found at automotive stores and costs around $8.00 per can.

Once again, keep sanding and priming until you are happy with the seams.

Once finished you should have a pile of parts that look like this.

DW Design

Active Hunter

Day 5

Take the two primered calves and spoons. Round the spoons off with a good size lip around the outside.

I like to use a large lip on the spoons. If you trim too much they will not hold well while trooping.

Trim out the trap door on the calves.

Now place the spoons into position. Draw a cut line for the spoons. Once again, I like to trim my calves

way up. It just more comfortable for me while trooping. You may want to experiment a bit on yours.

Finished trimmed pieces will look something like this.

Take the two primered calves and spoons. Round the spoons off with a good size lip around the outside.

I like to use a large lip on the spoons. If you trim too much they will not hold well while trooping.

Trim out the trap door on the calves.

Now place the spoons into position. Draw a cut line for the spoons. Once again, I like to trim my calves

way up. It just more comfortable for me while trooping. You may want to experiment a bit on yours.

Finished trimmed pieces will look something like this.

DW Design

Active Hunter

Day 6

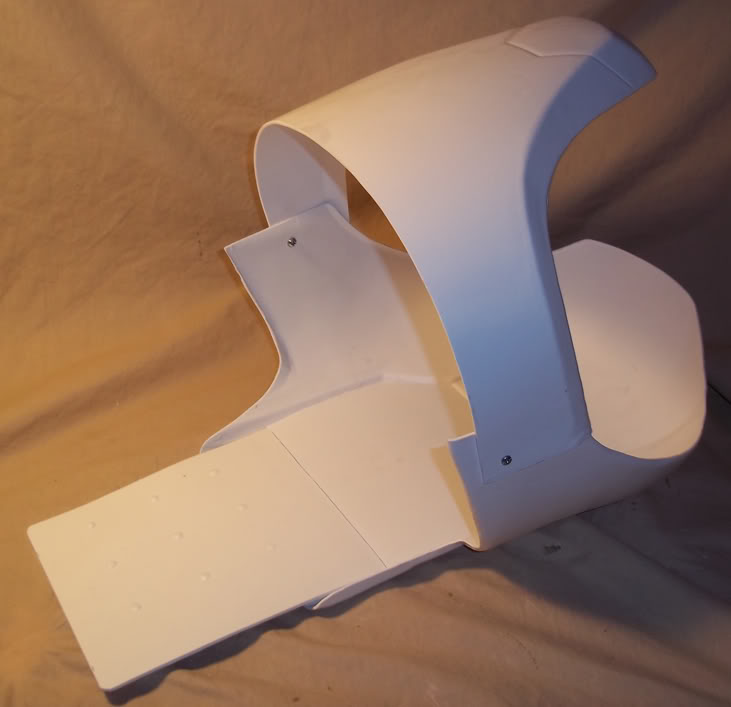

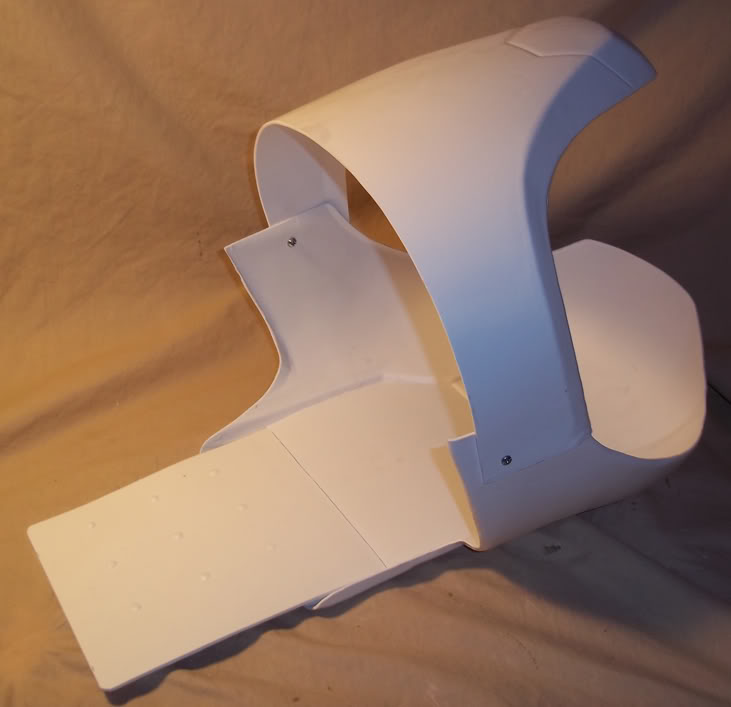

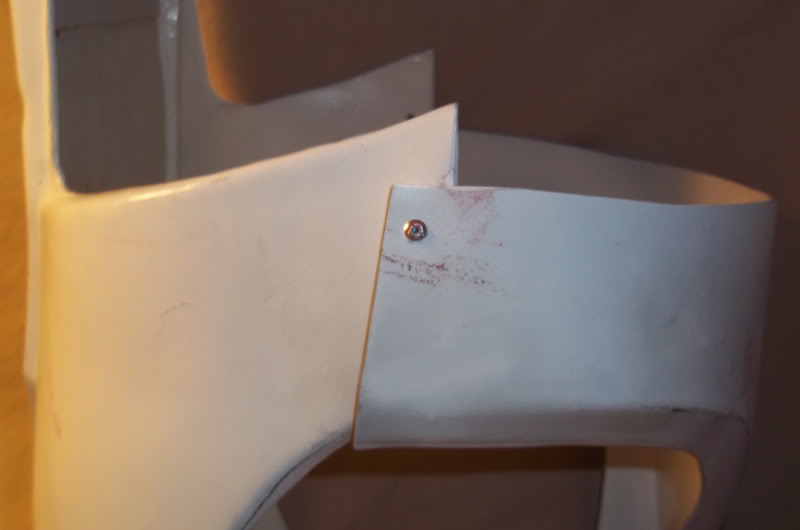

Cod and butt pieces. This piece consists of a vacuformed front and back. It also needs a piece of

plastic. This piece will be glued to the top of the butt area. The only reason for this piece is to keep

the back of the chest from slipping under the cod/butt while wearing the suit.

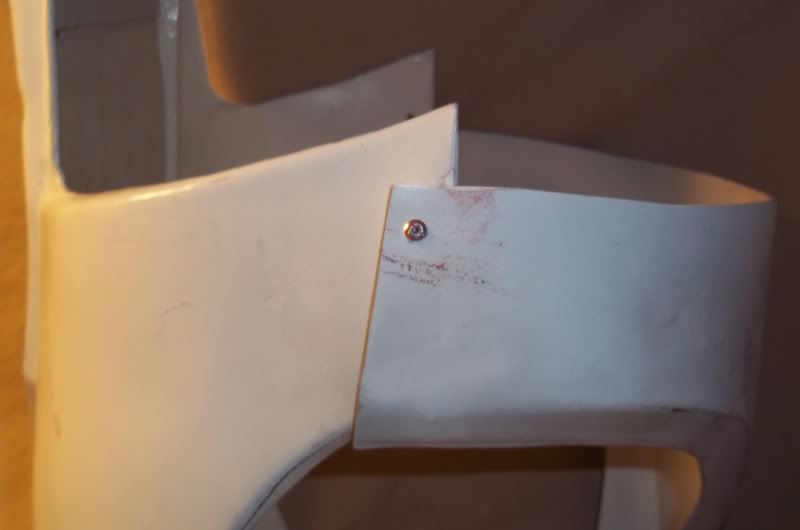

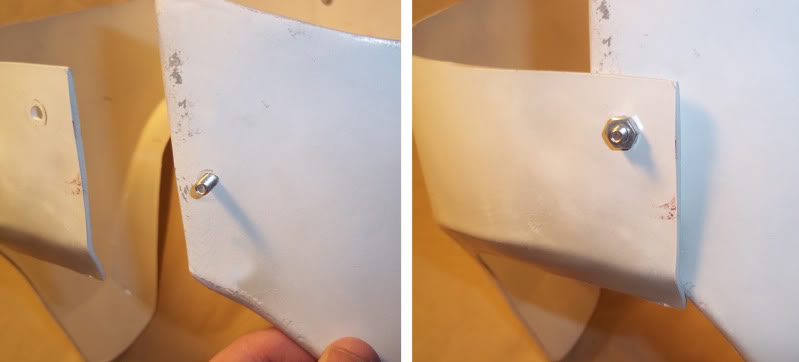

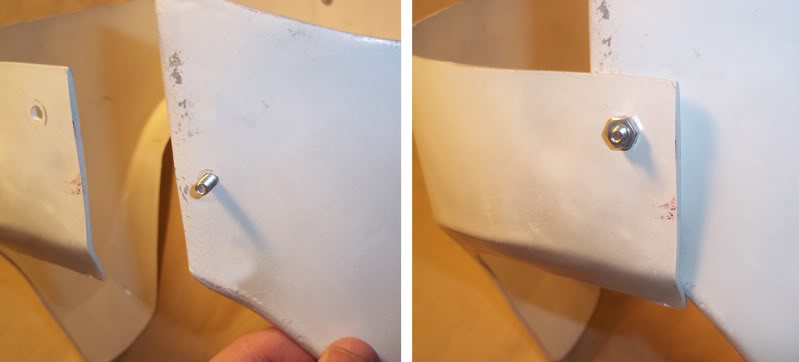

On the finished piece I have the right side connected with a pop rivet and

the left is connected with a nut and screw.

I always cut the front of the cod down. I usually trim about a 1 1/4” off.

Cleanup is always easier with a half round file.

Drill holes in both the front and the back pieces on both sides.

Check position and fit now with the use of screws and nuts.

This should fit snugly on you while wearing your black under suit.

Glue the plastic sheet to the back as shown. Use your epoxy for this.

Round the top edges to help of the glued plastic piece to hlep keep from getting poked while trooping.

Here are some finished photo to help show how it should look once assembled and painted.

Cod and butt pieces. This piece consists of a vacuformed front and back. It also needs a piece of

plastic. This piece will be glued to the top of the butt area. The only reason for this piece is to keep

the back of the chest from slipping under the cod/butt while wearing the suit.

On the finished piece I have the right side connected with a pop rivet and

the left is connected with a nut and screw.

I always cut the front of the cod down. I usually trim about a 1 1/4” off.

Cleanup is always easier with a half round file.

Drill holes in both the front and the back pieces on both sides.

Check position and fit now with the use of screws and nuts.

This should fit snugly on you while wearing your black under suit.

Glue the plastic sheet to the back as shown. Use your epoxy for this.

Round the top edges to help of the glued plastic piece to hlep keep from getting poked while trooping.

Here are some finished photo to help show how it should look once assembled and painted.

DW Design

Active Hunter

Day 7

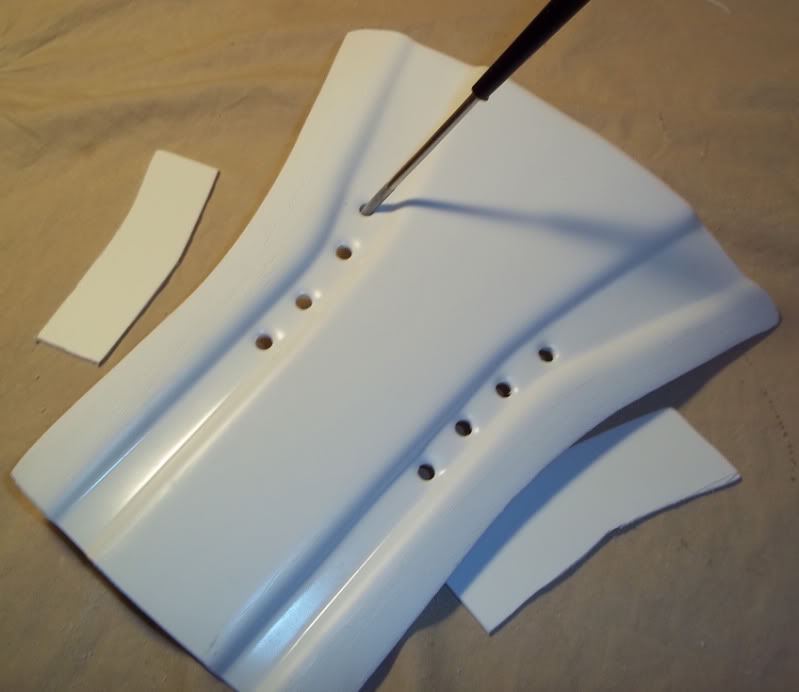

The stomach section consists of two different sides and a center piece. I also try to include extra

plastic to put behind the holes in the center section. It's not necessary to drill out these hole but

I prefer the depth that this gives the piece. Below is a photo of the kit pieces along with a finished version.

Use a drill to punch out the holes then clean up with a small file. I don’t add the extra plastic pieces

to the part until I am finished priming the final completed piece.

The center stomach section needs to be raised up higher than the two side pieces.

This is so you don't see any black under suit while trooping.

It help with the contour of the chest piece which curves up in this area. You will have to mark and cut a new trim line for this.

Using the epoxy glue this center section to the two side pieces. You should only do one section at a time

and allow to dry completely before moving onto the other half. I like to use large clips to hold the pieces

into place. Sorry, I forgot to take a photo here.

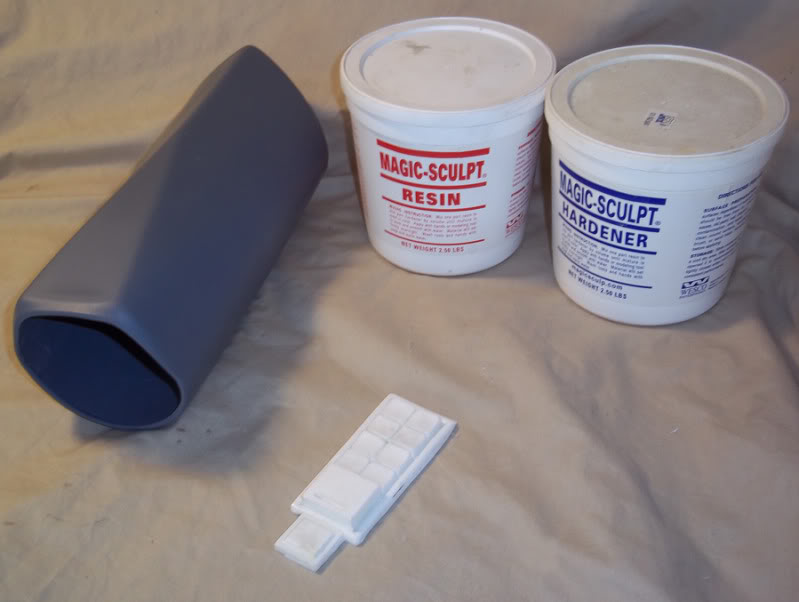

Once the center piece is good and dry we will now add the magic sculpt to the seam. Bondo will also work

here. I prefer the magic sculpt because it takes longer to set and can be sculpted with water while its still soft.

The magic sculpt will need to dry overnight. Once dried you can sand as needed. Once sanded, primer the piece.

Use epoxy to glue the small pieces to the back side. Your piece should now look something like the last photo attached.

The stomach section consists of two different sides and a center piece. I also try to include extra

plastic to put behind the holes in the center section. It's not necessary to drill out these hole but

I prefer the depth that this gives the piece. Below is a photo of the kit pieces along with a finished version.

Use a drill to punch out the holes then clean up with a small file. I don’t add the extra plastic pieces

to the part until I am finished priming the final completed piece.

The center stomach section needs to be raised up higher than the two side pieces.

This is so you don't see any black under suit while trooping.

It help with the contour of the chest piece which curves up in this area. You will have to mark and cut a new trim line for this.

Using the epoxy glue this center section to the two side pieces. You should only do one section at a time

and allow to dry completely before moving onto the other half. I like to use large clips to hold the pieces

into place. Sorry, I forgot to take a photo here.

Once the center piece is good and dry we will now add the magic sculpt to the seam. Bondo will also work

here. I prefer the magic sculpt because it takes longer to set and can be sculpted with water while its still soft.

The magic sculpt will need to dry overnight. Once dried you can sand as needed. Once sanded, primer the piece.

Use epoxy to glue the small pieces to the back side. Your piece should now look something like the last photo attached.

DW Design

Active Hunter

Day 8

Today we are going to work with several different pieces for the suit. The shoulder bells, hand backs and finish

working on the right forearm.

The shoulder bells are fairly straight forward. Cut and sand the edge to get ready for the primer.

The hand back are the same, cut and sand as needed.

Now we are going to add the resin compad to the right forearm. Place the resin piece approximately 3/4”

up from the front along the inside seam. Add the magic sculpt and cleanup as needed.

Allow the magic sculpt to dry then sand and primer as needed.

Well at this point we should have more than half of the parts trimmed,assembled and primered.

We have worked on the calves with spoons, thighs, cod and butt, stomach, shoulder bells, biceps, forearms and hand backs.

This should leave the knees, belt, thermal detonator, chest and back, and elbows.

Today we are going to work with several different pieces for the suit. The shoulder bells, hand backs and finish

working on the right forearm.

The shoulder bells are fairly straight forward. Cut and sand the edge to get ready for the primer.

The hand back are the same, cut and sand as needed.

Now we are going to add the resin compad to the right forearm. Place the resin piece approximately 3/4”

up from the front along the inside seam. Add the magic sculpt and cleanup as needed.

Allow the magic sculpt to dry then sand and primer as needed.

Well at this point we should have more than half of the parts trimmed,assembled and primered.

We have worked on the calves with spoons, thighs, cod and butt, stomach, shoulder bells, biceps, forearms and hand backs.

This should leave the knees, belt, thermal detonator, chest and back, and elbows.

clonecollector

Well-Known Hunter

Day 6

Cod and butt pieces. This piece consists of a vacuformed front and back. It also needs a piece of

plastic. This piece will be glued to the top of the butt area. The only reason for this piece is to keep

the back of the chest from slipping under the cod/butt while wearing the suit.

On the finished piece I have the right side connected with a pop rivet and

the left is connected with a nut and screw.

I always cut the front of the cod down. I usually trim about a 1 1/4” off.

Cleanup is always easier with a half round file.

Drill holes in both the front and the back pieces on both sides.

Check position and fit now with the use of screws and nuts.

This should fit snugly on you while wearing your black under suit.

Glue the plastic sheet to the back as shown. Use your epoxy for this.

Round the top edges to help of the glued plastic piece to hlep keep from getting poked while trooping.

Here are some finished photo to help show how it should look once assembled and painted.

I'd like to see how this turns out. I'm using snaps on the OSCS set I'm currently working on but I'm afraid they will come aparts

Similar threads

- Replies

- 0

- Views

- 32

- Replies

- 14

- Views

- 2,514

- Replies

- 1

- Views

- 1,576

Similar threads

- Replies

- 14

- Views

- 2,514

- Replies

- 1

- Views

- 1,576