SPY007

Active Hunter

I am always trying to come up with ways to build my own stuff. It is much more fun and challenging. Here is what I came up with for knee darts.

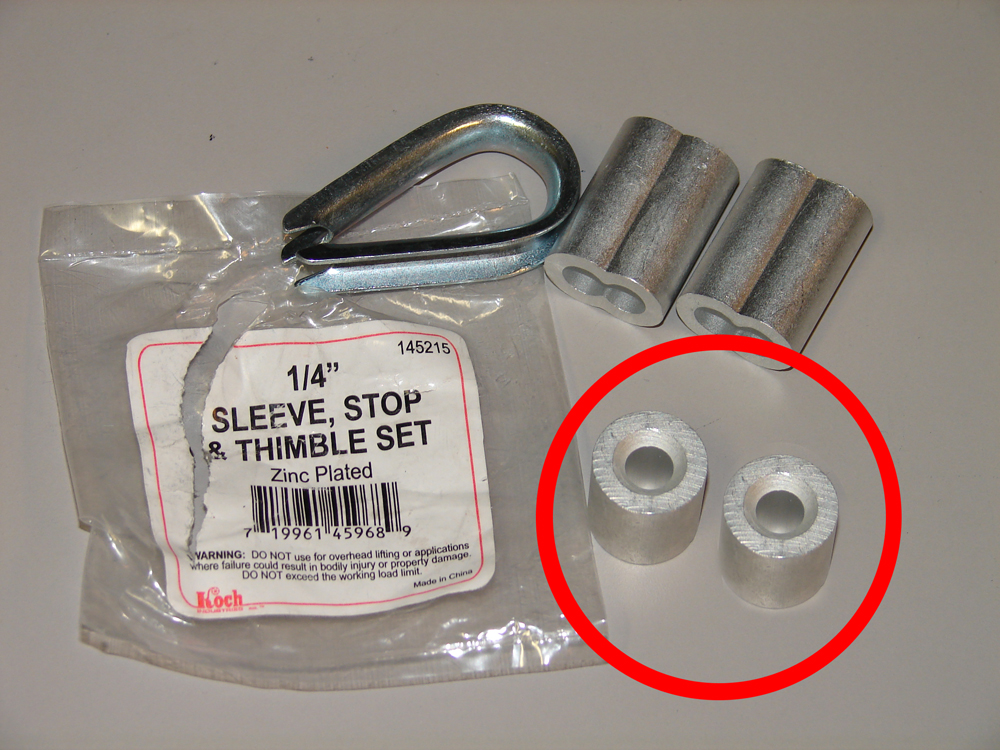

These were made using the WOF blue prints. The cost of materials was only about $5. The materials needed were several sets of “Cable Stops” purchased for 57 cents each at Menards. They are up to $3 a set elsewhere. (The rest of the part in the set were not needed) I also used half inch and three eighth inch aluminum rod purchased at a metal supply shop. I bought 2 feet off each, much more than needed.

Tools needed were a vice, vice grip, hacksaw, table mounted belt sander and drill press, metal files, a thread tapping tool, sand paper, steel wool, two metal spacers and JB Weld.

To make the pointed dart, I simply cut a few inch length off the half inch rod, put it in the drill press like a bit, turned on the drill and ground down a tip with a course file, fine file and sandpaper. Once I was satisfied with the shape and smoothness, I let it spin against some steel wool. I then cut of the excess rod, carefully drilled the hole in the tip and one in the back that was ‘tapped’ with bolt threads.

The other darts were more complicated. I first put the cable stops into a vice – making sure to put the parts that would get discarded in the vice as to leave no tool marks on my needed part. Again, using the WOF blueprints, I cut off the excess. Both cut cable stops needed some leveling on the belt sander.

The shorter, cable stop that became the back ‘ring’, was wrapped in cardboard, squeezed in a vice grip and drilled out with a half in bit on the drill press. The longer cable stop was drilled in the same manner, but one end was drilled just less than half way thru with the half inch bit, while the other end was drilled just less than half way through with a three eighth in bit. A small ridge remained in the middle.

I put a piece of half in rod through the back ring and into the half inch hole on the other cable stop. I laid this over the blue print, marked the half inch rod and cut it to the needed length.

I did the same with the three eight rod in the front. To drill the front holes nicely centered, I dropped a half inch metal spacer over the three eight rod that became the tip. It fit perfectly. I then put a three eight spacer inside the half inch spacer. This made a great drill guide. (Ace Hardware)

These parts were laid on the blue prints to insure they were streight and JB Welded together. I drilled and threaded the back hole, put in a headless bold, then put the bolt on the drill chuck and spun the piece against steel wool. Depending on the smoothness of the rods, some were sanded in the drill press before being cut to the needed lengths. The headless bolt was removed and of course I made three of these dart. Shown are two darts on my fiberglass knee pad that is in need of new paint.

If I did not have all the needed tools or access to them, this would not be a cost effective project. It took most of a Saturday to finish. It may have been easier to buy machined ones, but I am happy with how they turned out.

These were made using the WOF blue prints. The cost of materials was only about $5. The materials needed were several sets of “Cable Stops” purchased for 57 cents each at Menards. They are up to $3 a set elsewhere. (The rest of the part in the set were not needed) I also used half inch and three eighth inch aluminum rod purchased at a metal supply shop. I bought 2 feet off each, much more than needed.

Tools needed were a vice, vice grip, hacksaw, table mounted belt sander and drill press, metal files, a thread tapping tool, sand paper, steel wool, two metal spacers and JB Weld.

To make the pointed dart, I simply cut a few inch length off the half inch rod, put it in the drill press like a bit, turned on the drill and ground down a tip with a course file, fine file and sandpaper. Once I was satisfied with the shape and smoothness, I let it spin against some steel wool. I then cut of the excess rod, carefully drilled the hole in the tip and one in the back that was ‘tapped’ with bolt threads.

The other darts were more complicated. I first put the cable stops into a vice – making sure to put the parts that would get discarded in the vice as to leave no tool marks on my needed part. Again, using the WOF blueprints, I cut off the excess. Both cut cable stops needed some leveling on the belt sander.

The shorter, cable stop that became the back ‘ring’, was wrapped in cardboard, squeezed in a vice grip and drilled out with a half in bit on the drill press. The longer cable stop was drilled in the same manner, but one end was drilled just less than half way thru with the half inch bit, while the other end was drilled just less than half way through with a three eighth in bit. A small ridge remained in the middle.

I put a piece of half in rod through the back ring and into the half inch hole on the other cable stop. I laid this over the blue print, marked the half inch rod and cut it to the needed length.

I did the same with the three eight rod in the front. To drill the front holes nicely centered, I dropped a half inch metal spacer over the three eight rod that became the tip. It fit perfectly. I then put a three eight spacer inside the half inch spacer. This made a great drill guide. (Ace Hardware)

These parts were laid on the blue prints to insure they were streight and JB Welded together. I drilled and threaded the back hole, put in a headless bold, then put the bolt on the drill chuck and spun the piece against steel wool. Depending on the smoothness of the rods, some were sanded in the drill press before being cut to the needed lengths. The headless bolt was removed and of course I made three of these dart. Shown are two darts on my fiberglass knee pad that is in need of new paint.

If I did not have all the needed tools or access to them, this would not be a cost effective project. It took most of a Saturday to finish. It may have been easier to buy machined ones, but I am happy with how they turned out.

Last edited by a moderator: