You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Expert eye needed on scratchbuild

- Thread starter goodus10

- Start date

welshwarrior123

Active Hunter

Ive been watching this thread for a while now and im really enjoying following the scratch build. I thought the work you did to fix the dent was superb, looks much better. I really like the nice crisp details youve got on the helmet and the mould youve done looks spot on. Youve got a very good looking lid there in my opinion, do you plan on doing a run?. I look forward to seeing your first pull,

Lewis

Lewis

Thanks guys. I really appreciate your kind words. Thank you for the compliments on the dent. After spending all that time on the dome, it was kind of a tough decision to dig a new hole in the lid but I agree, it does look much better.

I was quite happy with the mould, but there are a fair few airblows unfortunately. As I said in my previous entry, I would do a few things differently next time to make it better. I would be more than happy to do a run of these so I plan to do a new mould once I've repaired my keyslot and I'll get back to you.

I may do a separate thread on moulding if anyone's interested. It seems there have been some requests before on various other threads.

I did a prototype pull a couple of evenings ago, despite the airblows and I'll upload the photos when I get chance.

Thanks for following this guys. It means a lot when you know someone is interested in the stuff that you're doing.

I was quite happy with the mould, but there are a fair few airblows unfortunately. As I said in my previous entry, I would do a few things differently next time to make it better. I would be more than happy to do a run of these so I plan to do a new mould once I've repaired my keyslot and I'll get back to you.

I may do a separate thread on moulding if anyone's interested. It seems there have been some requests before on various other threads.

I did a prototype pull a couple of evenings ago, despite the airblows and I'll upload the photos when I get chance.

Thanks for following this guys. It means a lot when you know someone is interested in the stuff that you're doing.

welshwarrior123

Active Hunter

Mate the pull looks really good. Almost all moulds have imperfections and airbubbles. Nothing a little filler and primer wont fix . I would seriously be interested in one if you do get a run goin. At the moment ive just spent quite a bit on a boba belt, so right now it is out of the question, but I imagine you wont start a run for a bit yet.

. I would seriously be interested in one if you do get a run goin. At the moment ive just spent quite a bit on a boba belt, so right now it is out of the question, but I imagine you wont start a run for a bit yet.

Now go an slap some paint on that lid

great work,

lewis

Now go an slap some paint on that lid

great work,

lewis

Couple of weeks!!!!! that was optimistic. It's been crazy here with one thing and another. Ended up being away for a while. Diploma course taking up most of my time. Changing my job after thirteen years in the same place (So relieved, far less stress). I have revisited my helmet today though, and remade the keyslot on the original and doing some tidying up. Much happier. I will be posting some pics soon once I've tweaked all I want to tweak then I'll do a run through of the moulding process. That seems to be requested quite a lot. I'm no expert but I'll do my best and I hope it helps the ones that haven't attempted it yet! That's about it for now. Back to the real world. Cheers.

welshwarrior123

Active Hunter

Hehe lifes more important than this stuff, hope your new job is goin well. Good to see you starting this back up.

O and pm sent

Welsh

O and pm sent

Welsh

Back on the project at last. Sorry if anyone's been following this and is wondering what's going on. I decided to remould the helmet. I was never happy with the first one. So I'm just gathering some photos together and I'll run through my mould with a couple of tips for any of you guys new to this like me. Hopefully it will help you avoid some of the mistakes I made and save you time, and a fair bit of money (silicone is not cheap). So bear with me a bit longer, I've just run out of materials and I've got an order in. I'm getting there.

Right then. Been busy. Mould number 2. Quick run through of the process and highlighting some mistakes I made previously that I have hopefully now put right. Would like to think this will help some chaps that are new to this too. Sorry if it seems obvious to a lot of you, but I know some of you are a bit nervous about moulding as I was. Any advice for your first mould, especially learning from the mistakes of others, I think is very useful.

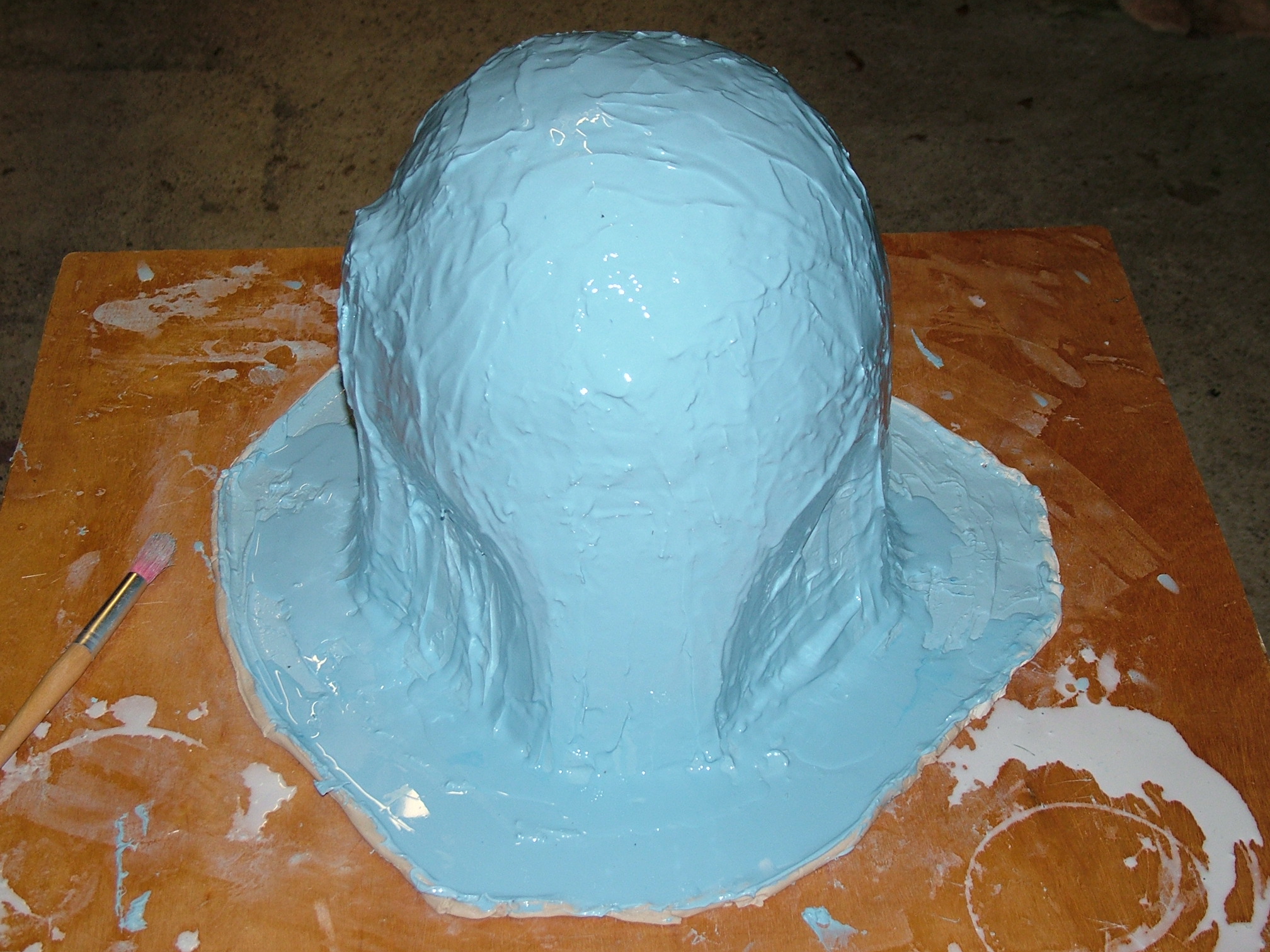

First thing is get your measurements right. Didn't do this on very first attempt and had a disaster. Another thing is the first layer is your detail. Make sure all the air bubbles are gone. Leave the rubber to settle as in the pics. This was after leaving the silicone twenty minutes. Had lots of air bubbles on my first mould so made sure I left it longer this time.

After this, brush it on. Made sure to leave a nice wide base this time too.

First thing is get your measurements right. Didn't do this on very first attempt and had a disaster. Another thing is the first layer is your detail. Make sure all the air bubbles are gone. Leave the rubber to settle as in the pics. This was after leaving the silicone twenty minutes. Had lots of air bubbles on my first mould so made sure I left it longer this time.

After this, brush it on. Made sure to leave a nice wide base this time too.

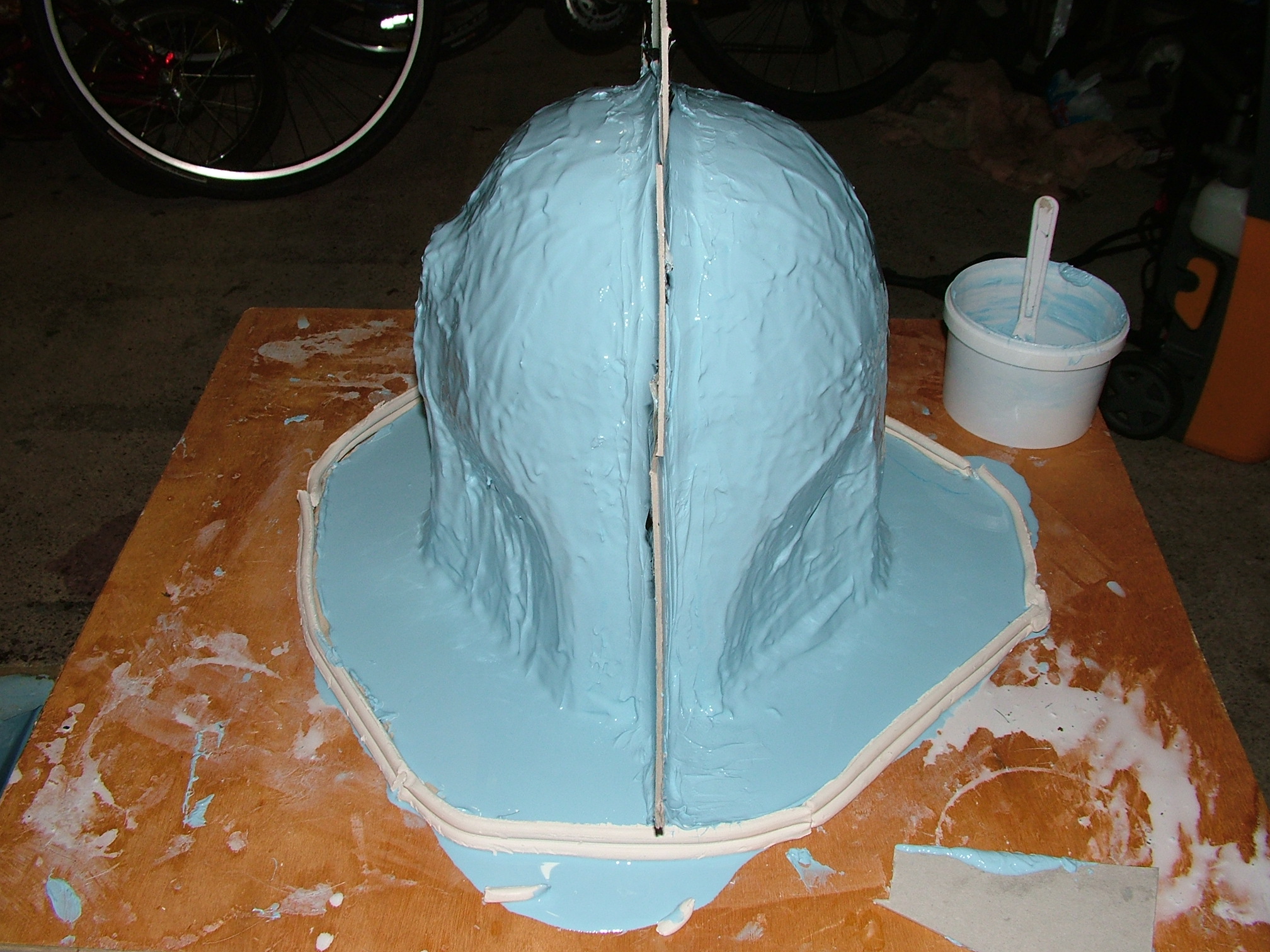

Ok, next stage once the first layer has gone off, is to build up the layers. I was planning on getting a much thicker mould this time so it would hold it's shape in the support cast much better than the one before when I was getting an uneven cast. so decided not to skimp on the rubber! It's expensive stuff, but it's even more of a problem if you find the final result is no good and it's gone to waste.

Mix up your silicone and add the thixotropic agent. This will thicken it up and stop it running off the mould. The first layer has captured the fine detail, now it's a case of thickening it up. It will look quite rough at this stage. Tried to keep it free of undercuts and big uneven lumps as much as possible. Added three layers.

Mix up your silicone and add the thixotropic agent. This will thicken it up and stop it running off the mould. The first layer has captured the fine detail, now it's a case of thickening it up. It will look quite rough at this stage. Tried to keep it free of undercuts and big uneven lumps as much as possible. Added three layers.

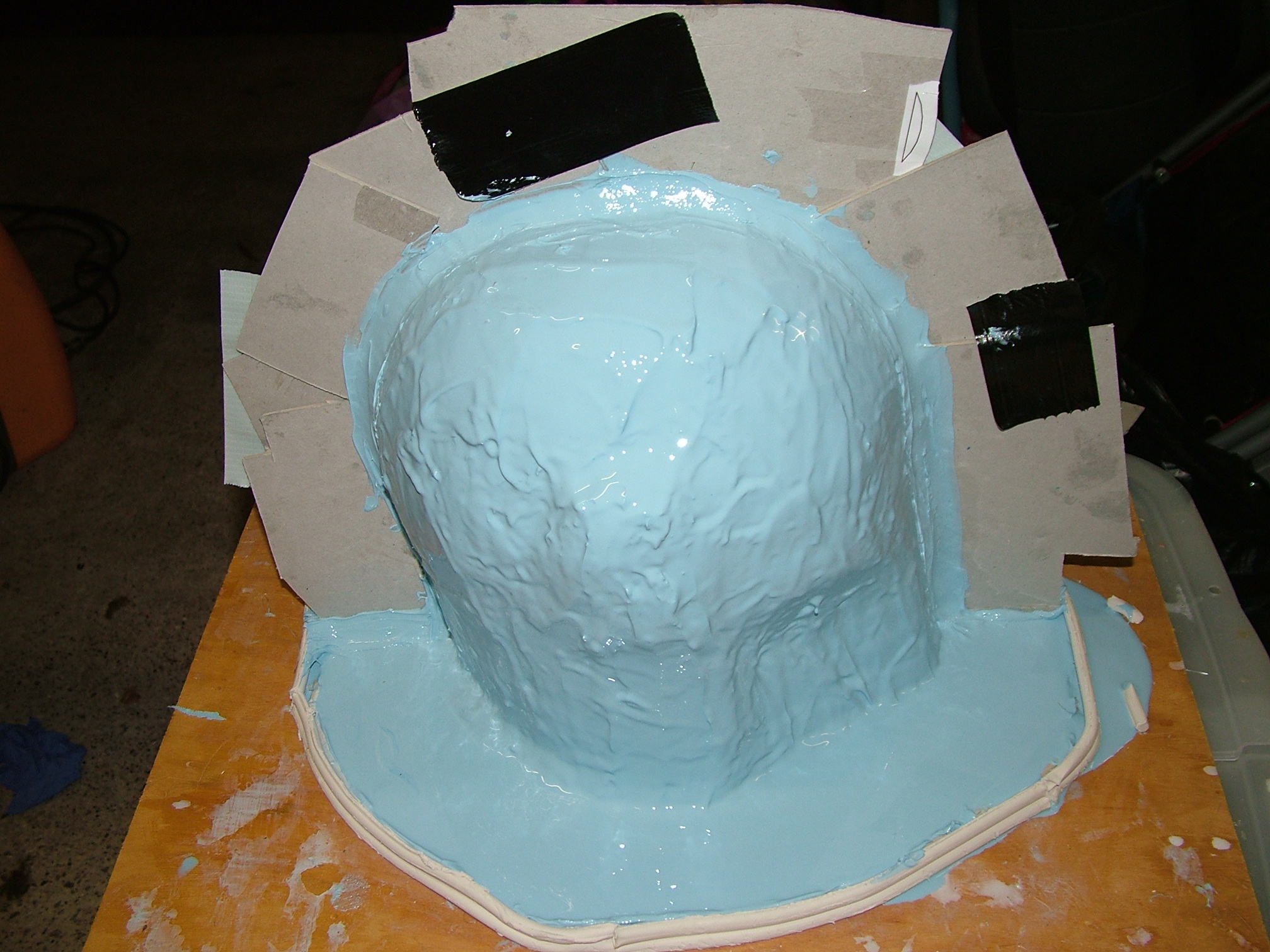

Next stage, after I was happy with the mould thickness, was to add the fin and key for the support cast. Did this by placing some cardboard offcuts around the midline and then run a bead of thixo'd silicone to hold it in place both sides.

After this I added some beads of silicone down the sides of the mould to act as a key, so it will sit accurately in the support cast. It was still quite uneven at this stage so I added thin layer of unthickened silicone to smooth out some of the irregularities. The smoother the rubber, the better it will sit in the support cast.

After this I added some beads of silicone down the sides of the mould to act as a key, so it will sit accurately in the support cast. It was still quite uneven at this stage so I added thin layer of unthickened silicone to smooth out some of the irregularities. The smoother the rubber, the better it will sit in the support cast.

Mould done, support cast next. Smelly bit. Wear an aspirator.

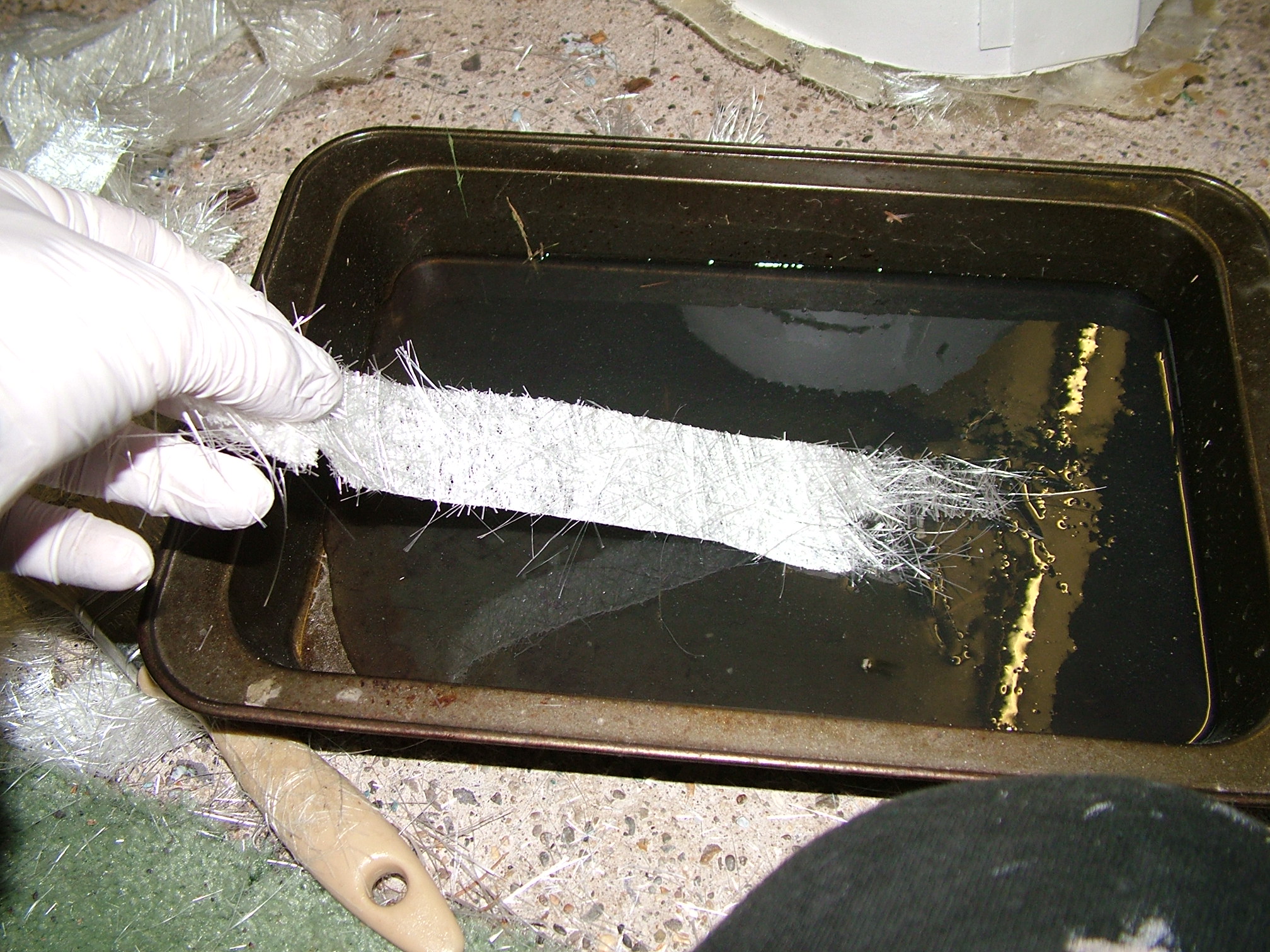

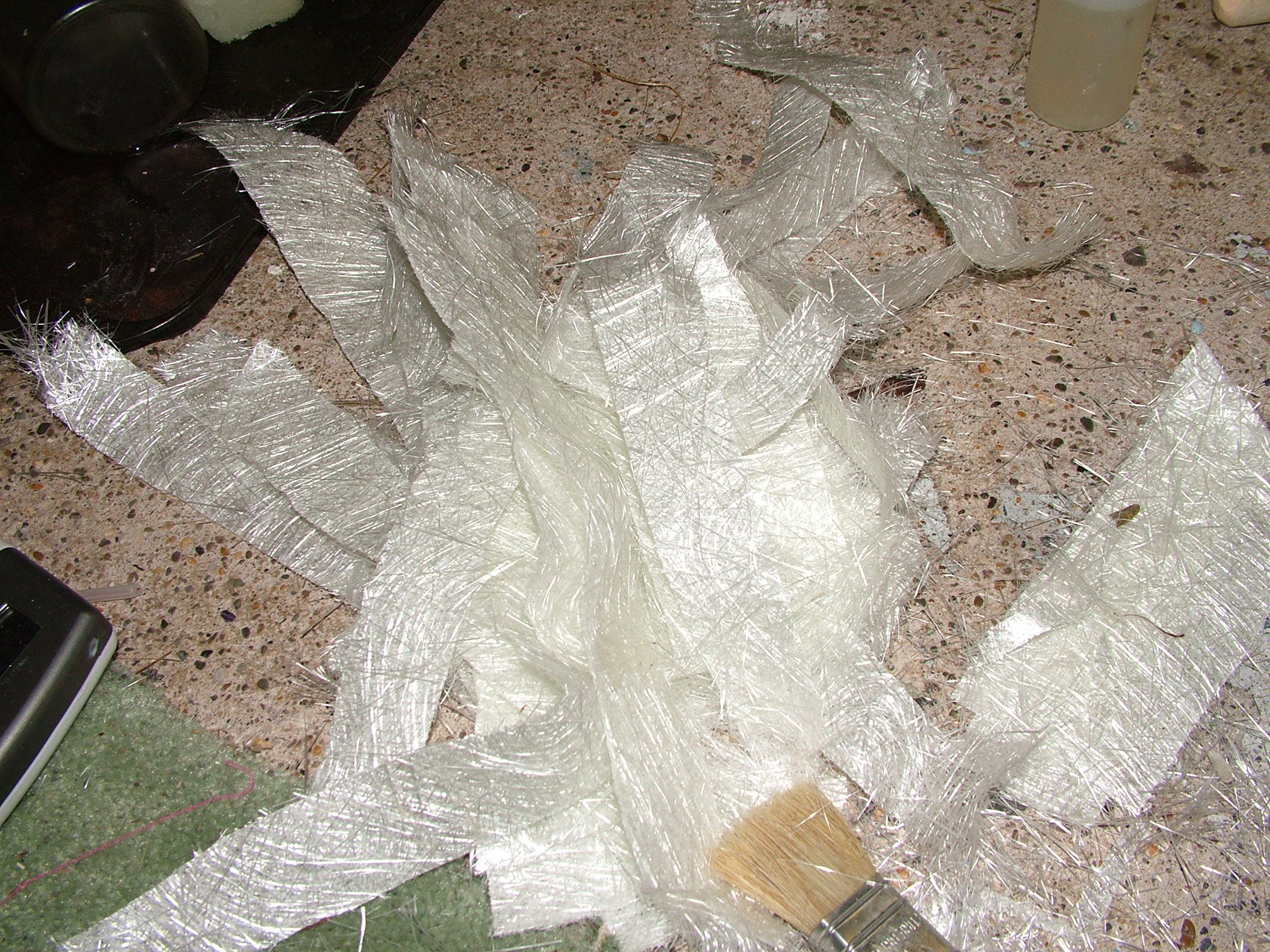

Don your rubber gloves and cut up some matting. prepare your resin and I found it useful in a tray. Wet your matting and lay on one side of the mould and fully cover that side. Any dry bits of matting then use a brush to make sure its all wetted with resin.

After it has hardened then remove the cardboard and place some silver foil as a separator. Repeat with resin and matting on this side. I added another layer in some of the thinner areas after this but this isn't on the photos.

Don your rubber gloves and cut up some matting. prepare your resin and I found it useful in a tray. Wet your matting and lay on one side of the mould and fully cover that side. Any dry bits of matting then use a brush to make sure its all wetted with resin.

After it has hardened then remove the cardboard and place some silver foil as a separator. Repeat with resin and matting on this side. I added another layer in some of the thinner areas after this but this isn't on the photos.

Lookin good brother! I love doing this stuff also! What brand/ version of silicone rubber are you using? I use rebound 25 from smooth on and have found it excellent. Ive pulled over 20 Vader buckets from a mold made of that stuff and its still going strong. The mix ratio is 1:1 so its easier to mix as well. I am actully doing a run of Fett buckets in the new year. It was also made from scratch like yours. Excellent work brother!

Then it's a case of demoulding the thing. That was a sweaty, sweary half an hour. Silicone sticks very well to anything with a grain ie. wood. I'd placed mine on plywood. Wow.

I did try to save my original, but as the mould was so much thicker and the support cast was so much stronger, it did not come off so well as you can see by the pics. Retrievable I think but I was a bit upset after all that work getting it as good as I could. However, I now had a fine mould to make as many lids as I wanted!!!!

I must admit I was quite pleased with my efforts. now to cast a bucket!

I did try to save my original, but as the mould was so much thicker and the support cast was so much stronger, it did not come off so well as you can see by the pics. Retrievable I think but I was a bit upset after all that work getting it as good as I could. However, I now had a fine mould to make as many lids as I wanted!!!!

I must admit I was quite pleased with my efforts. now to cast a bucket!

Similar threads

- Replies

- 4

- Views

- 1,054