You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Darktrooper Progress Thread 8MAR2011: Getting back to it

- Thread starter tubachris85x

- Start date

tubachris85x

Well-Known Hunter

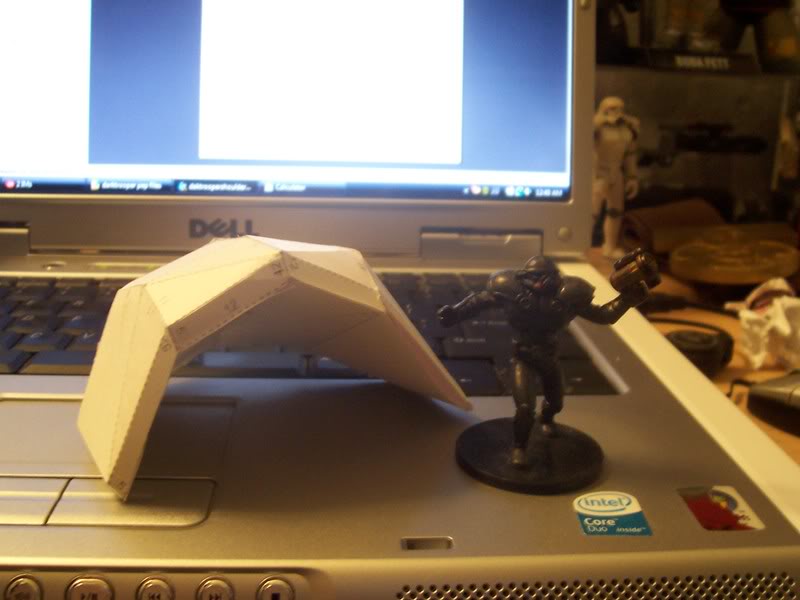

And this is why I'll never be an engineer....This was supposed to be 8 inches tall..turned out to only be about 2 1/2...Man I hate scaling on this program :wtc:

Last edited by a moderator:

tubachris85x

Well-Known Hunter

My first shoulder pad was big enough for my two year old, the second one I built is huge. But the right size.

lol good to see you had good luck the second time around..the first one I ever built was probably the size good enough for a 12 inch figure, but man, scaling on this program is almost hit or miss.

The defult took the 8 inch conversion and made it only 2 1/2, so I did some more math, and it should be about 65 centimeters based on the set scale..which sound's weird, but should work next time out.

Last edited by a moderator:

CombatBaby

Well-Known Hunter

glad to see you at it again!

Last edited by a moderator:

tubachris85x

Well-Known Hunter

I think the top part of the shoulder for me was 27 cm. It is hit or miss, I wish you could just push print and it would spit it out in my size, covered in ABS filled with foam.

If it were only that easy

Last edited by a moderator:

CombatBaby

Well-Known Hunter

If it were only that easy

it does that when you own a 3d printer

Last edited by a moderator:

CombatBaby

Well-Known Hunter

Chris....

i never asked this before..

you're planning to do hybrid suits? vacc'd armor parts and fiberglass helmet?

or are you doing one master helmet and then making vacc bucks later.

vacc'ing that thing would be cheap compared to silicone molding and fiberglassing..

just a thought.. you could make a 3 part dark trooper helmet mold with a set of detail pieces formed on the side.

just tossing ideas out

i never asked this before..

you're planning to do hybrid suits? vacc'd armor parts and fiberglass helmet?

or are you doing one master helmet and then making vacc bucks later.

vacc'ing that thing would be cheap compared to silicone molding and fiberglassing..

just a thought.. you could make a 3 part dark trooper helmet mold with a set of detail pieces formed on the side.

just tossing ideas out

Last edited by a moderator:

tubachris85x

Well-Known Hunter

Well the plan right now is to keep it within my budget. I figure I can always go back and correct things/improve materials later on. I plan to make the helmet mold, and slush cast them in plastic resin. As for the armor itself, right now everything from the shins up to the ab and arm pieces will be ABS plastic. The shoulder, back and chest will be fiberglass as of right now.

Last edited by a moderator:

tubachris85x

Well-Known Hunter

Well not much to report, but I got up early this morning, and finished fiberglassing the chest piece. So that's all nice and sturdy now! However, I soon after passed out and woke up just before the super bowl lol

Going to hopefully be able to do the back armor, but man, there is no clean way of fiberglassing at all

Going to hopefully be able to do the back armor, but man, there is no clean way of fiberglassing at all

Last edited by a moderator:

tubachris85x

Well-Known Hunter

Well the good news is that I was finally able to make the shoulders the right size and it fits me perfect.

The bad news, is what I had feared earlier, that my chest piece is too big. Yep, I just wasted alot of fiberglass

-TC

The bad news, is what I had feared earlier, that my chest piece is too big. Yep, I just wasted alot of fiberglass

-TC

Last edited by a moderator:

CombatBaby

Well-Known Hunter

Well the good news is that I was finally able to make the shoulders the right size and it fits me perfect.

The bad news, is what I had feared earlier, that my chest piece is too big. Yep, I just wasted alot of fiberglass

-TC

What do you mean by 'too big' Chris?

Is it a seam issue? or does it expand too far past the side of the chest so that it doesn't have a proper curve.

This by sound silly....but have you tried the idea of scoring and cracking it to the right shape? (only if you've been using fiberglass weave, not bondo)

you might be able to correct your curve and then smooth it out again

just trying to help you salvage your work

Last edited by a moderator:

tubachris85x

Well-Known Hunter

What do you mean by 'too big' Chris?

Is it a seam issue? or does it expand too far past the side of the chest so that it doesn't have a proper curve.

This by sound silly....but have you tried the idea of scoring and cracking it to the right shape? (only if you've been using fiberglass weave, not bondo)

you might be able to correct your curve and then smooth it out again

just trying to help you salvage your work

This is what I've actually been thinking about, the scoring/cracking thing. My first mistake was that when I fiberglassed the upper chest (the larger flat section) I made it completly flat-it is supposed to bend down the center. So what I'm thinking is cutting a straight line down the center (not cutting all the way through) so that I can bend it the way it's sopposed to be. From that, I'll re-fiberglass it as it sits in the proper shape.

As for the sides..I'm going to have to trim them if I want to be able to salvage them. When the center is shaped after I score it, it should theoretically push the upper portion of the chest closer to each other (in a sense) and I'll be able to use it. But right now, until I can get that bend back into the center, it won't look right. One more thing to add-if you notic, the 3d chest/back has along the edges of the piece, a "wall" to appear thick I guess, but I'm going to be cutting those off to make it appear as the thickness of regular vac-formed armor.

So yea...

Jangojedi-Unfortunatly, I'll only be using this piece as the final chest. I'll be bondoing it, and scuplting the rest of the details via bondo. I really wish I could afford to mold the pieces, but it's just not at this time. I'll update you as soon as I can about the arm molds.

Thanks guys

-TC

Last edited by a moderator:

GCNgamer128

Sr Hunter

I say vac it. Fiberglassing means it will only fit one specific body type.

Last edited by a moderator:

I definitely agree with GCN, however if it is not in the budget, FG is very cheap. If all you want to do is a one time version. I have made many things out of FG and then pulled a lighter weight and flexible copy. The major problem, that everyone know with that is it will crack and chip everytime you handle it.

Hey Chris I will post some more pics here later today.

Hey Chris I will post some more pics here later today.

Last edited by a moderator:

Ijaat Ka rta

Hunter

I've been watching this thread from the start and I must say this is really impresive. There is not way I would have been able to accoplish this in any way shape or form. Keep up the good work!

Last edited by a moderator:

tubachris85x

Well-Known Hunter

The only cheap way I know of to vac-form this would only result in a one time cast, because I can't see it lasting for more then one, maybe two.

:/ If I can talk to my guy whos going to be forming my arm pieces, but even then, I don't think his vac-former would even be large enough for the chest. The way he does his bucks, is that after he sculpts it, he fills the interior of the buck, and the outside with this really dense foam, from smoothon I think, and sands the excess, molds it, and then makes a solid cast in a high strength resin

The foam itself goes for about $90, then pluse the silicone, could be about $150, just for the one mold...so yea..

:/ If I can talk to my guy whos going to be forming my arm pieces, but even then, I don't think his vac-former would even be large enough for the chest. The way he does his bucks, is that after he sculpts it, he fills the interior of the buck, and the outside with this really dense foam, from smoothon I think, and sands the excess, molds it, and then makes a solid cast in a high strength resin

The foam itself goes for about $90, then pluse the silicone, could be about $150, just for the one mold...so yea..

Last edited by a moderator:

Similar threads

- Replies

- 1

- Views

- 1,576

- Replies

- 2

- Views

- 1,485

- Replies

- 0

- Views

- 5,005

- Replies

- 4

- Views

- 6,262

Similar threads

- Replies

- 1

- Views

- 1,576

- Replies

- 0

- Views

- 5,005