clonecollector

Well-Known Hunter

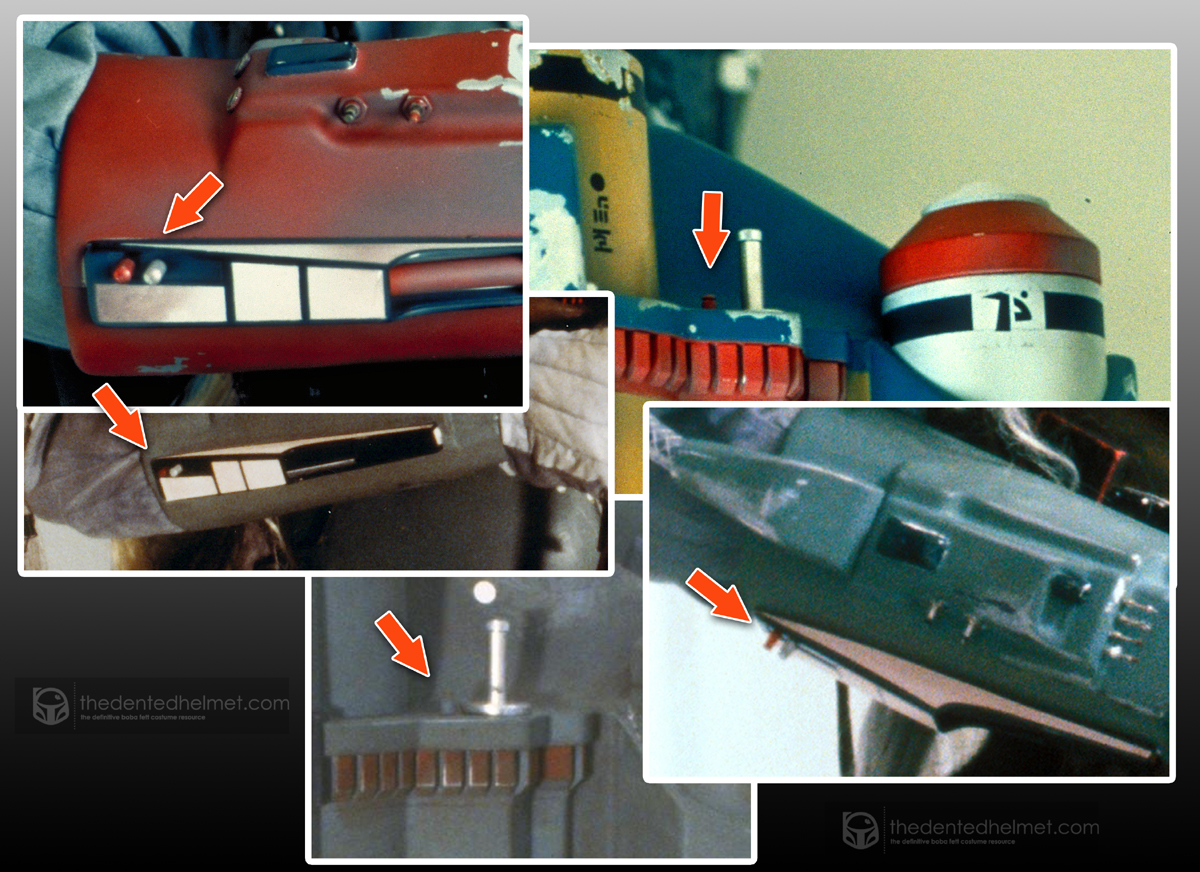

I completely didn't make a connection here with the nubs being the same as the ones on the ESB guantlet... and I never noticed the nub on the ESB jetpack! Wow! Thanks Spidey!

Im sure most of you knew, but these can also be found on the Supertrooper, PrePro1, and ESB Gauntlets and Jetpack...