mattman1138

Hunter

Hello All,

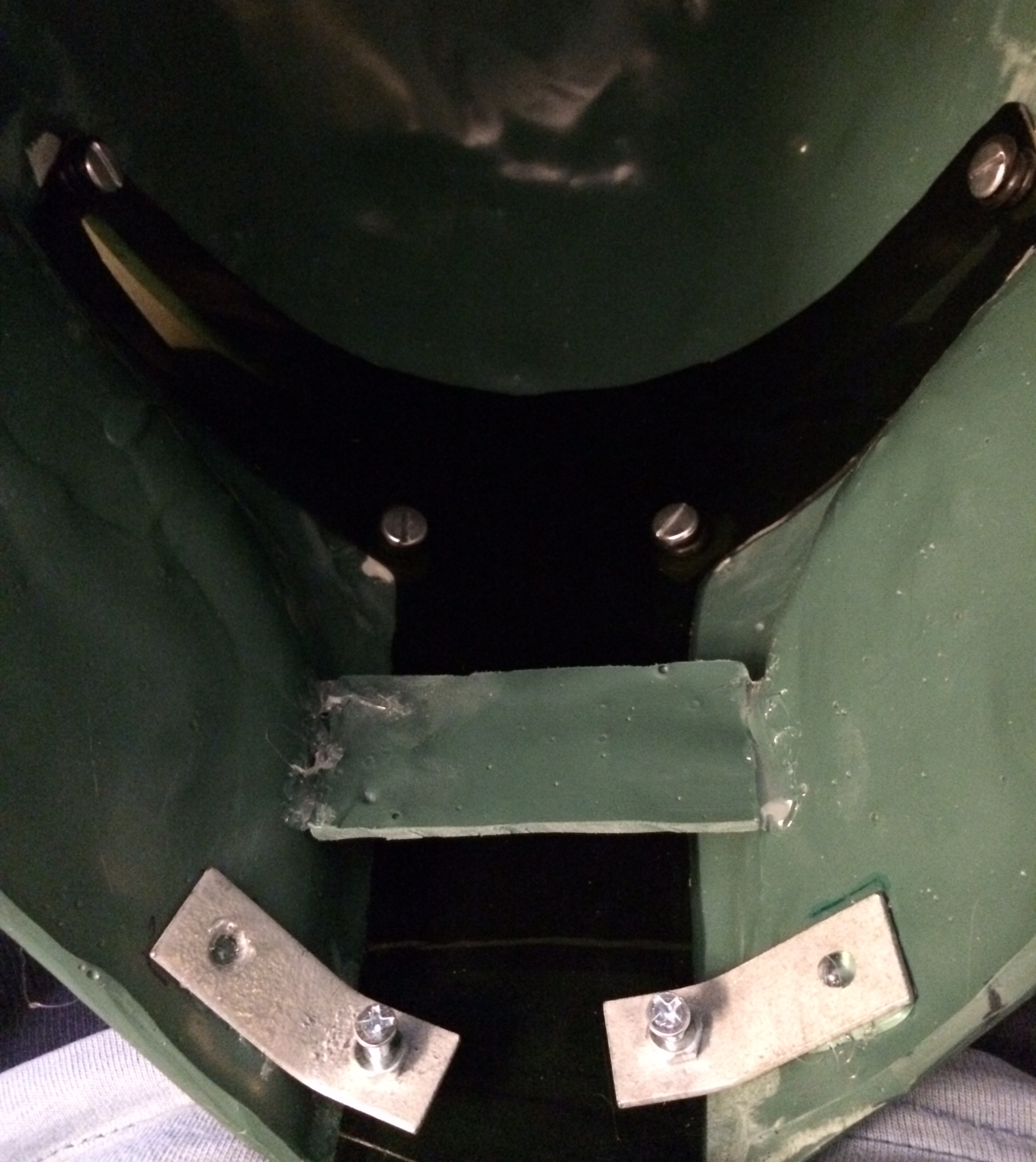

I'm a huge Boba Fan and when I decided to join the 501st, he was the only costume I wanted to do. I just started working on my budget helmet recently received from Animefan. I've never actually done ANY costuming so this is slow going for me. It also doesn't help that I am quite the perfectionist LOL. Luckily I bought a 96 Don Post Helmet back when they were still making them. It's the lowest end Vinyl version but it serves me well by allowing me to test out my techniques for visor installation and painting before I move on to the real deal. So far I've installed a visor in the Post helmet by cutting out the vinyl and using binding posts to anchor the visor down. I wanted it to be replaceable if need be. I also had to glue a piece of the vinyl inside the helmet to help try and keep the helmets shape as best I could. I've now moved on to the Budget bucket. It's been meticulous sanding and filling, but I'm ready to now start working on the visor and installing it. Can't wait to get to painting lol. Just wanted to keep a record here of my progress. Comments and questions are most welcome. Thanks all!

Mattman1138

I'm a huge Boba Fan and when I decided to join the 501st, he was the only costume I wanted to do. I just started working on my budget helmet recently received from Animefan. I've never actually done ANY costuming so this is slow going for me. It also doesn't help that I am quite the perfectionist LOL. Luckily I bought a 96 Don Post Helmet back when they were still making them. It's the lowest end Vinyl version but it serves me well by allowing me to test out my techniques for visor installation and painting before I move on to the real deal. So far I've installed a visor in the Post helmet by cutting out the vinyl and using binding posts to anchor the visor down. I wanted it to be replaceable if need be. I also had to glue a piece of the vinyl inside the helmet to help try and keep the helmets shape as best I could. I've now moved on to the Budget bucket. It's been meticulous sanding and filling, but I'm ready to now start working on the visor and installing it. Can't wait to get to painting lol. Just wanted to keep a record here of my progress. Comments and questions are most welcome. Thanks all!

Mattman1138

Last edited by a moderator: